Acid cyanide-free electrogalvanizing technique with LHE (low-hydrogen embrittlement)

A process method, electro-galvanizing technology, applied in the field of galvanizing process, can solve the problems affecting the progress of batch product production tasks, limited production capacity of cyanide galvanizing, operators and environmental hazards, and achieve low cost and strong corrosion resistance , the effect of good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

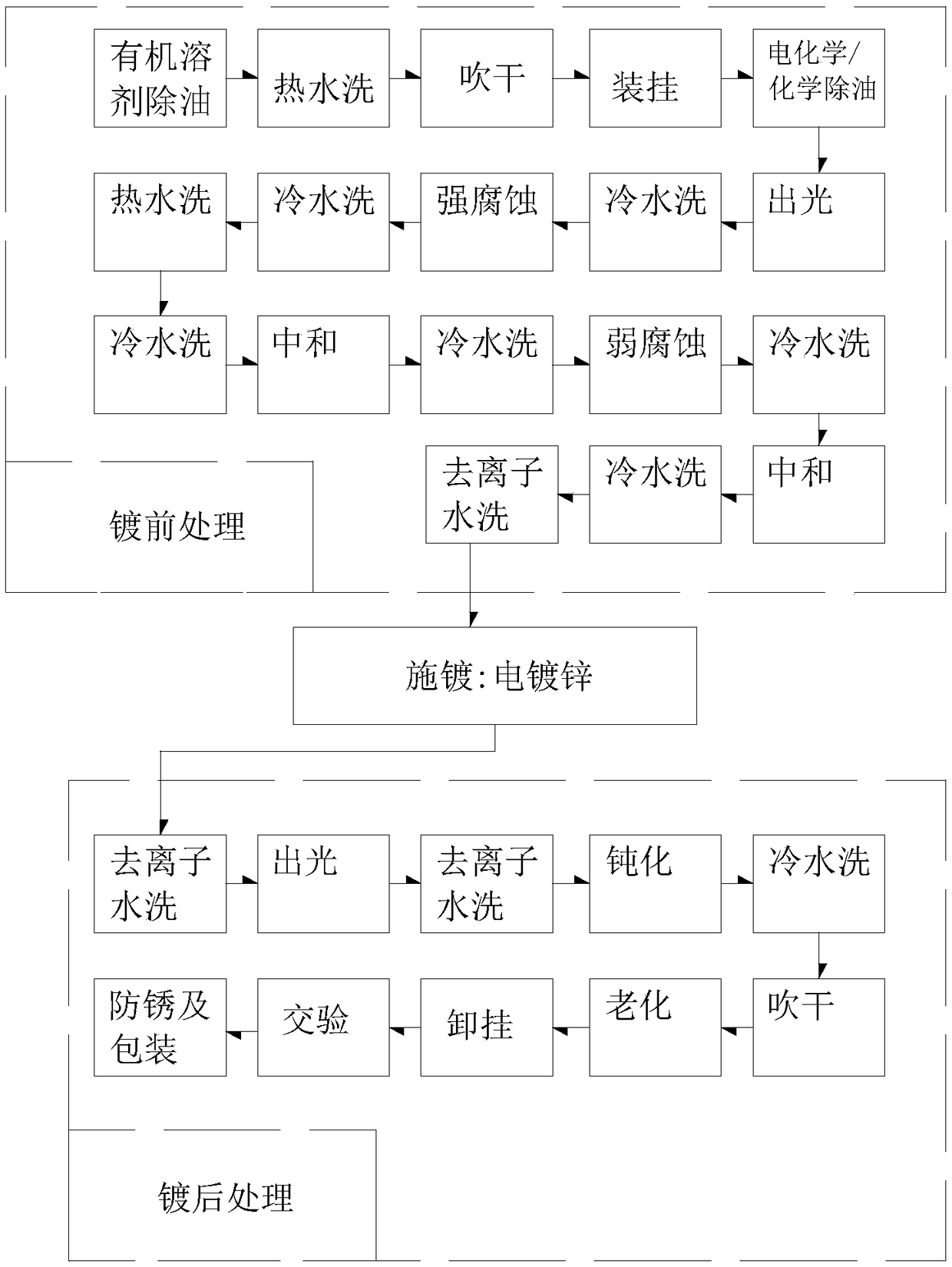

Image

Examples

Embodiment 1

[0058] Example 1: Galvanized saddle washer (D·Zn12)

[0059] 1) Organic solvent degreasing: soak the parts in a container filled with gasoline, scrub with absorbent cotton, then dry or place to dry;

[0060] 2) Wash in hot water

[0061] 3) blow dry

[0062] 4) Mounting and hanging: Bind and mount the parts through φ1 copper wire to ensure reliable mounting and hanging, and there is an even gap between each two pieces;

[0063] 5) Chemical degreasing: Carry out chemical degreasing treatment on the parts through alkaline degreasing solution, the degreasing temperature is 60-80°C, and the degreasing time is 6-8min; (due to the relatively high hardness of the parts, only chemical degreasing is performed) , the degreasing quality is checked by the water film continuous method, and the continuous time is not less than 30 seconds.

[0064] 6) Wash in hot water

[0065] 7) Wash in cold water

[0066] 8) Weak corrosion: put the parts into a weak acid solution for etching and acti...

Embodiment 2

[0083] Embodiment 2: Galvanized treatment of guide table (D·Zn25)

[0084] 1) Organic solvent degreasing: soak the parts in a container filled with gasoline, scrub with absorbent cotton, and then place them to dry;

[0085] 2) Wash in hot water

[0086] 3) blow dry

[0087] 4) Hanging,

[0088] 5) Electrochemical degreasing: degreasing through the cathode first, the current density is 5-10A / dm 2 , time 5-8min, then anode degreasing, current density 5-10A / dm 2 , the time is 1-2min, the degreasing temperature is 60-80°C, the degreasing quality is checked by the water film continuous method, and the continuous time is not less than 30 seconds to be qualified;

[0089] 6) Wash in hot water

[0090] 7) Wash in cold water

[0091] 8) Weak corrosion: put the parts into a weak acid solution for etching and activation treatment, the temperature of the bath solution is 10-35°C, and the time is 0.5-1min.

[0092] 9) Wash in cold water

[0093] 10) Neutralization: neutralize the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com