5G antenna stannous electroplating process

A tin electroplating and stannous electroplating technology, applied in jewelry and other directions, can solve the problems of failing to meet the requirements of 5G antenna tin plating, poor crystallinity of the coating, low bonding force, etc., to achieve good coating coverage, fine coating crystallization, and bonding good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

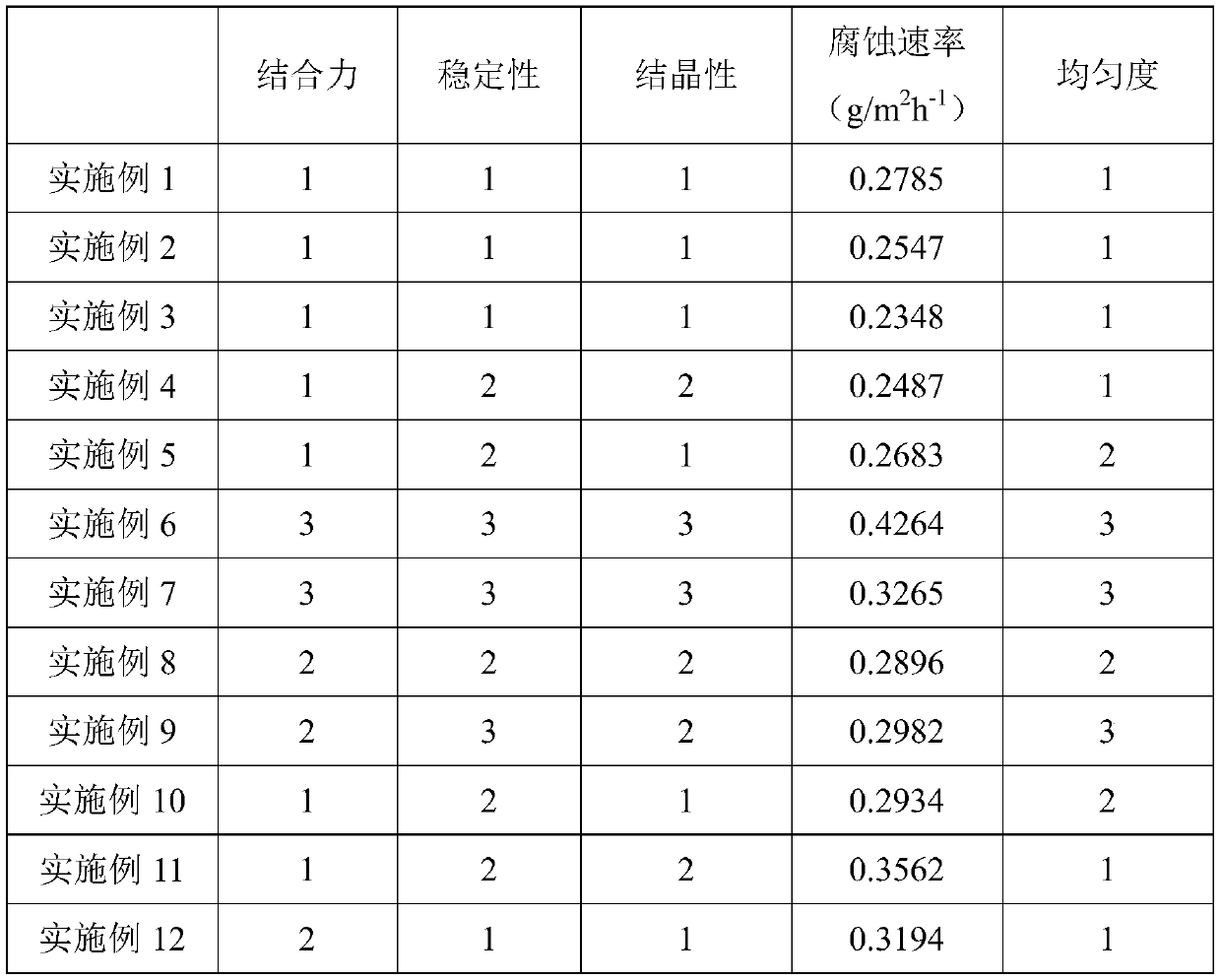

Examples

preparation example Construction

[0082] In one embodiment, the preparation method of the stannous electroplating additive comprises the steps of: first uniformly mixing polyether, hydroquinone, benzenesulfonic acid, and water in proportion, and then slowly adding an inorganic acid under stirring conditions, Mix evenly to obtain the stannous electroplating additive.

[0083] In one embodiment, the preparation method of the stannous electroplating solution comprises the steps of: mixing the stannous salt and distilled water uniformly, adding the stannous electroplating additive and stirring uniformly, then slowly adding sulfuric acid under stirring conditions, mixing uniformly, That is, the stannous electroplating solution is obtained.

[0084] The second aspect of the present invention provides a tin-plated 5G antenna, which is prepared by the above tin-tin electroplating process.

Embodiment 1

[0089] Embodiment 1 provides a 5G antenna tinous electroplating process, including the following steps:

[0090] S1: prepare stannous electroplating solution;

[0091] S2: Pour the tin-tin electroplating solution in S1 into the electroplating tank, use the copper-plated 5G antenna as the cathode, and use the carbon electrode as the anode, and the current density at the cathode is 30mA / cm 2 Lower electroplating;

[0092] The electroplating temperature of the S2 step is 20°C;

[0093] The electroplating time of the S2 step is 30min;

[0094] In parts by weight, the stannous electroplating solution in the S1 step includes: 20 parts of stannous salt, 280 parts of sulfuric acid, 10 parts of stannous electroplating additive, and 900 parts of distilled water;

[0095] The stannous salt is stannous sulfate;

[0096] Described sulfuric acid is the sulfuric acid that concentration is 98wt%;

[0097]In terms of mass percentage, the stannous electroplating additive includes: polyethe...

Embodiment 2

[0104] Embodiment 2 provides a 5G antenna tinous electroplating process, including the following steps:

[0105] S1: prepare stannous electroplating solution;

[0106] S2: Pour the stannous electroplating solution in S1 into the electroplating tank, use the copper-plated 5G antenna as the cathode, and use the carbon electrode as the anode, and the current density at the cathode is 70mA / cm 2 Lower electroplating;

[0107] The electroplating temperature of the S2 step is 30°C;

[0108] The electroplating time of described S2 step is 50min;

[0109] In parts by weight, the stannous electroplating solution of the S1 step comprises: 30 parts of stannous salt, 320 parts of sulfuric acid, 20 parts of stannous electroplating additives, and 1100 parts of distilled water;

[0110] The stannous salt is stannous sulfate;

[0111] Described sulfuric acid is the sulfuric acid that concentration is 98wt%;

[0112] In terms of mass percentage, the stannous electroplating additive include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com