High-temperature-resistant artificial crystal forming die steel material and preparation method thereof

A technology for artificial crystal and forming molds, applied in the direction of improving process efficiency, etc., can solve the problems of artificial crystal forming molds such as short service life, low product surface finish, low heat fatigue resistance, etc., and achieve the effect of eliminating internal defects and forging through Good, small self-diffusion coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to better explain the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with specific examples. The following examples are only illustrative technical solutions of the present invention, and do not limit the present invention in any form .

[0043] The following table 1 is the mass percentage list of the chemical components contained in the mold steel materials of various embodiments of the present invention;

[0044] Table 2 below is a list of values of various process parameters in the production methods of steel plates in various embodiments of the present invention.

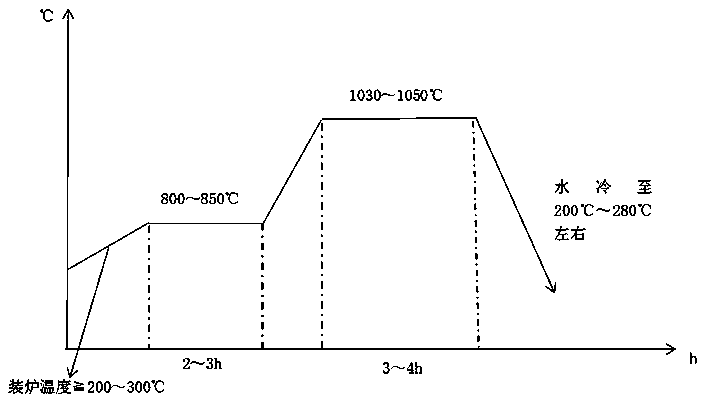

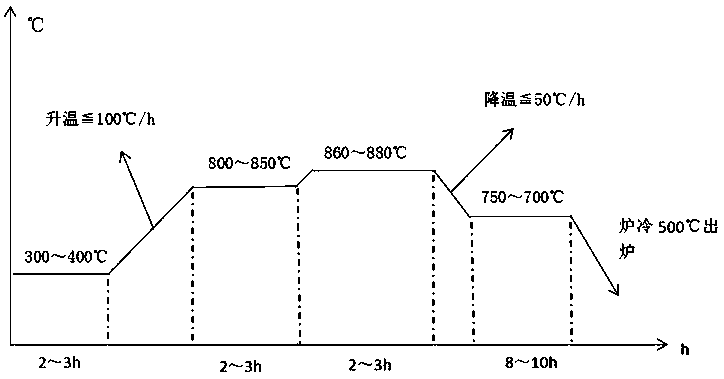

[0045] A kind of preparation method of high temperature resistant artificial crystal molding die steel material of the present invention, comprises the following steps:

[0046] (1) Ingredients: use 50% new iron material, 20% returned iron scrap material, and 30% returned iron block material. There mus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com