Granulation system with thermal protection function

A thermal protection and functional technology, applied in the field of granulation system with thermal protection function, can solve the chemical corrosion of granulator, high temperature erosion of granulator, failure to control the thickness and shape of slag shell formation, etc. problems, to achieve the effect of simple and easy installation, help thermal protection, and increase the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

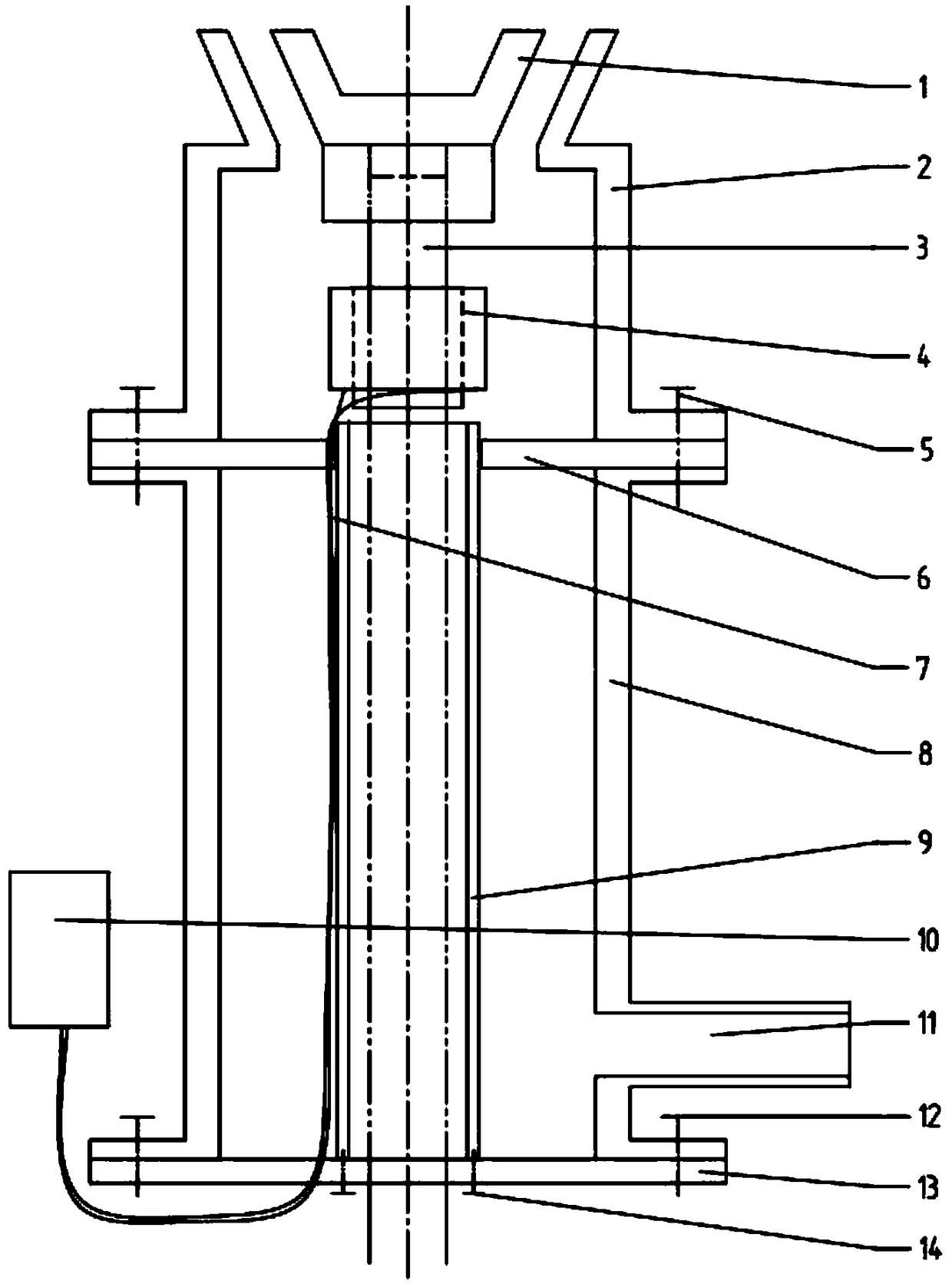

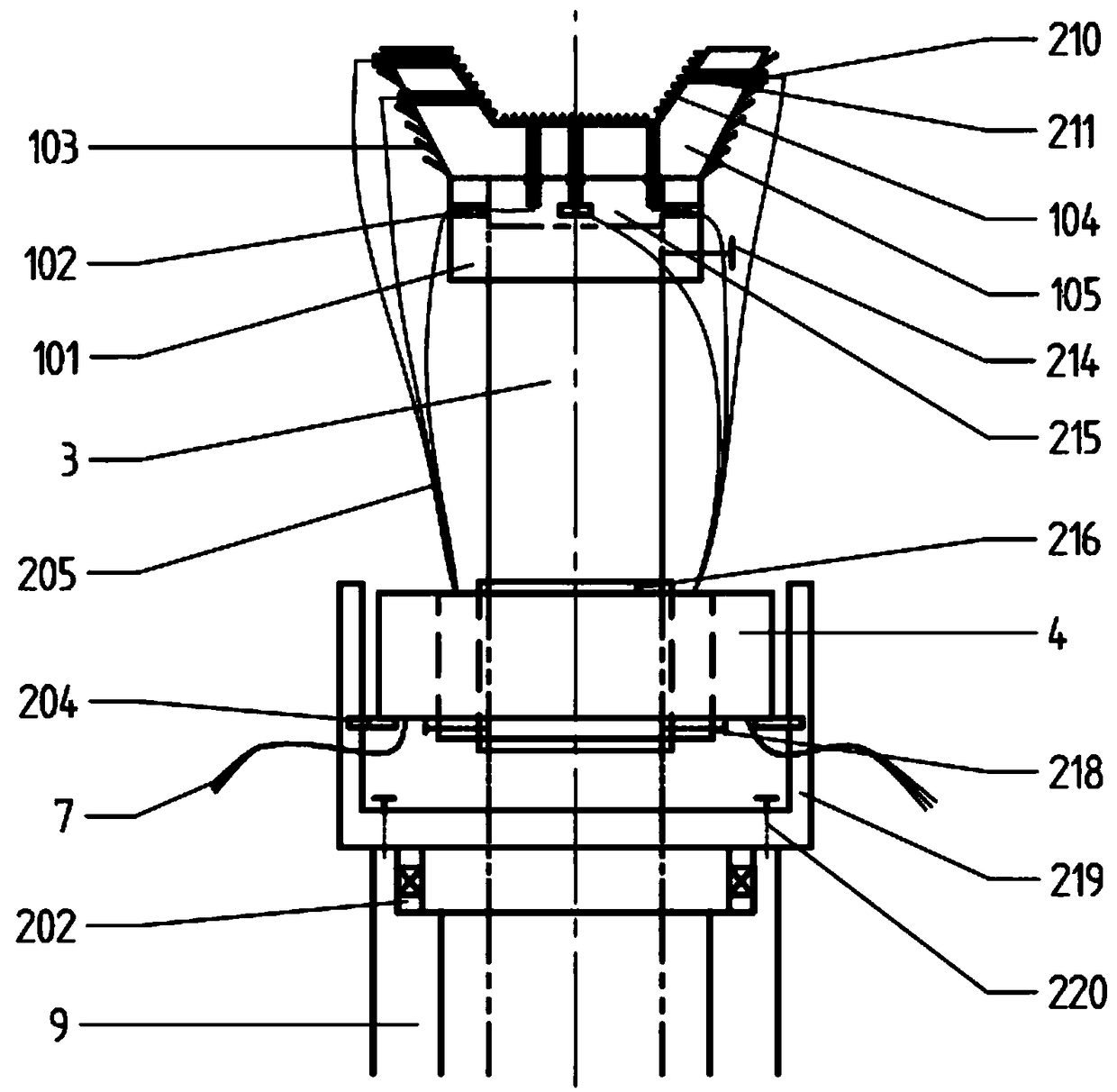

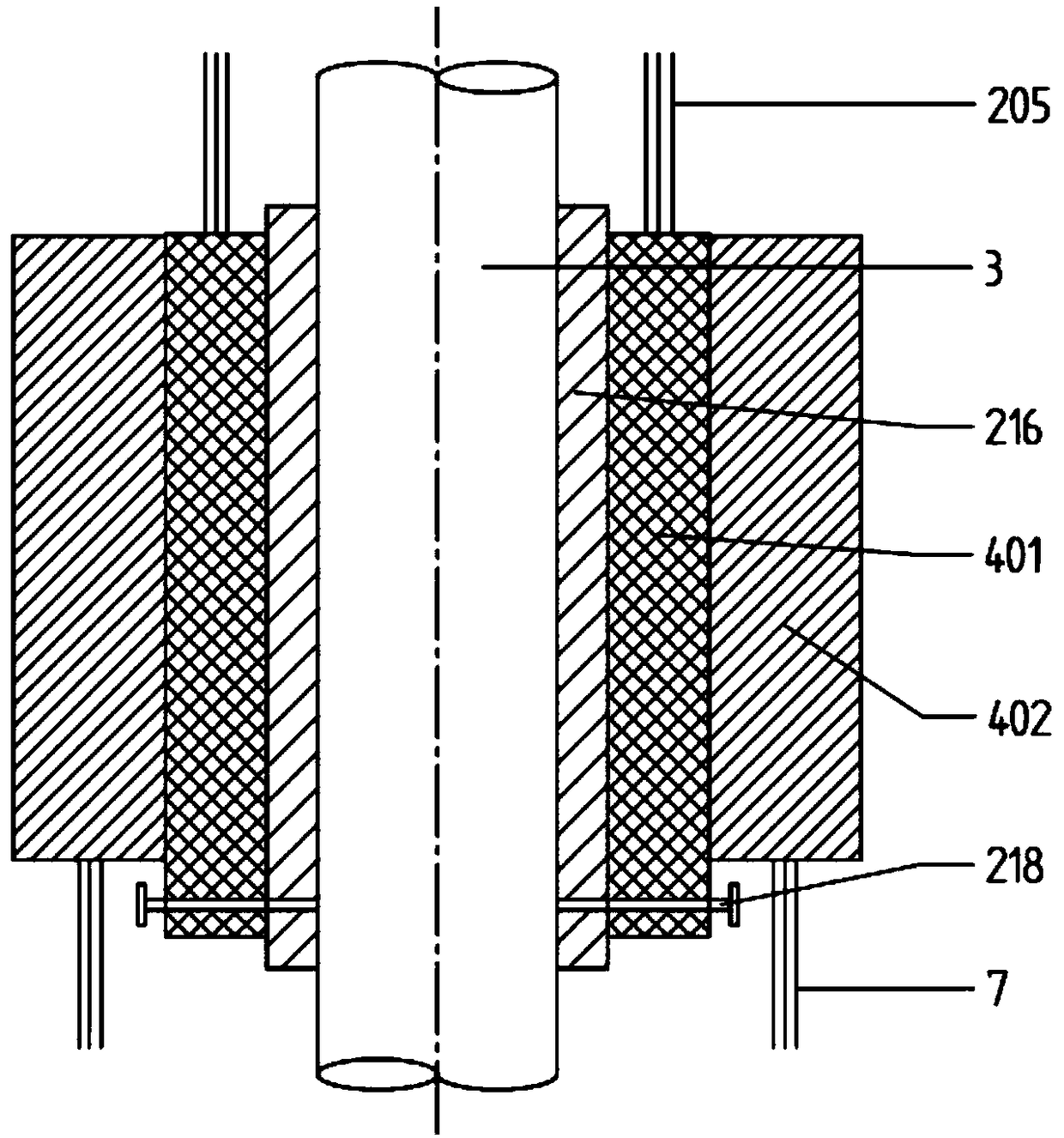

[0026] see Figure 1 to Figure 4 , a granulation system with heat protection function, comprising a rotating shaft 3, an auxiliary cooling air supply unit, a temperature monitoring unit and a granulator 1; the granulator 1 is fixed on the top of the rotating shaft 3; it is characterized in that:

[0027] The auxiliary cooling air supply unit provides cooling air for the temperature monitoring unit and the granulator 1; the auxiliary cooling air supply unit includes air cylinders 2, 8 and air inlet ducts 11; the air ducts are connected to the fan through the air inlet ducts 11; The temperature monitoring unit and the granulator 1 are arranged in the air duct;

[0028] The temperature monitoring unit includes a plurality of thermocouples 210, through-aperture conductive slip rings 4, anti-rotation plates 204 and anti-rotation devices 219; a plurality of thermocouples 210 are arranged in the granulator 1, and the granulator 1 A number of thermocouple mounting holes are provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com