Mucus type sealing agent doped with graded particles and preparation and using method thereof

A technology of particulate matter and sealing agent, which is applied in chemical instruments and methods, earthwork drilling, sealing/isolation, etc. It can solve problems such as failure to seal, new cracks that cannot be effectively sealed, cost of plugging technology, poor effect, etc. , to achieve the effect of improving sealing performance, increasing effective sealing time and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

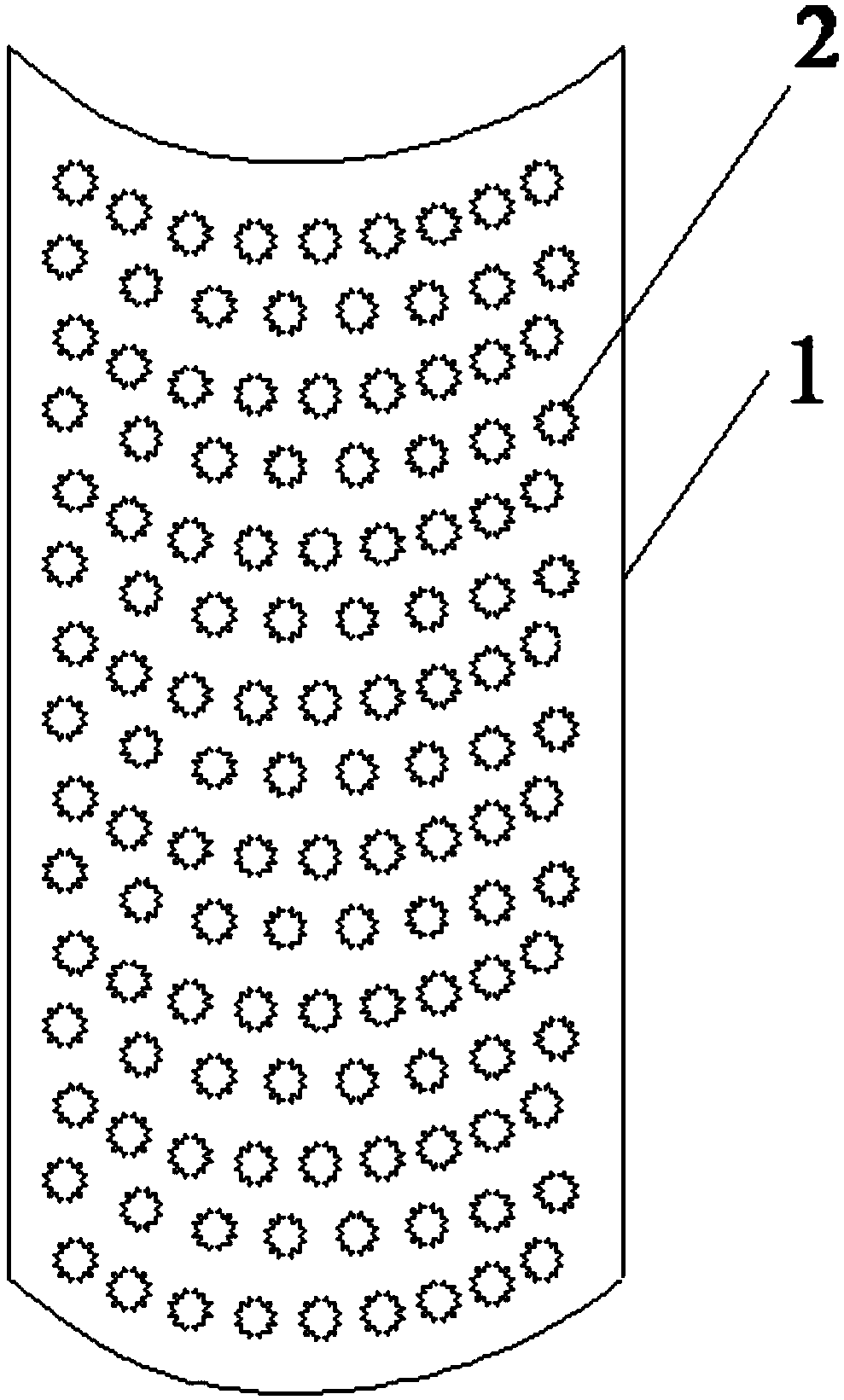

Image

Examples

Embodiment 1

[0024] A mucus type pore sealing agent mixed with graded particles, which is composed of the following components by weight: 5 parts of sodium carboxymethyl cellulose, 1 part of sodium polyacrylate, 2 parts of gelatin, 8 parts of graded granular talc, 0.05 parts of coconut oil fatty acid diethanolamide, 160 parts of water;

[0025] Among them, the mass ratio of the particle size of the graded particles is 5 to 3 mm: 3 to 1 mm: 1 to 0.4 mm: less than 0.4 mm=3:5:6:6.

[0026] First, weigh the warm water, sodium carboxymethyl cellulose, sodium polyacrylate, graded granular talcum powder, coconut oil fatty acid diethanolamide at about 50℃ according to the amount of material; then pour the warm water into the grouting tank, and then add the weighing The rest of the material is good, then stir with a stirrer for 1.5 minutes so that there is no large block of sodium carboxymethyl cellulose powder in the grouting barrel, and finally grouting under pressure, the slurry penetrates in the fis...

Embodiment 2

[0031] A mucus type pore sealing agent mixed with graded particles, composed of the following components by weight: 4 parts of hydroxyethyl cellulose, 1.5 parts of sodium polyacrylate, 2 parts of gelatin, 7 parts of graded granular calcium carbonate powder, 0.05 parts of coconut oil fatty acid diethanolamide, 140 parts of water;

[0032] Among them, the mass ratio of the particle size of the graded particles is 5 to 3 mm: 3 to 1 mm: 1 to 0.4 mm: less than 0.4 mm=2.4:5:6.3:6.3.

[0033] The preparation and use method is the same as in Example 1.

[0034] The plugging agent of this embodiment is suitable for the situation where the cracks in the surrounding rock of the borehole are poorly developed and the borehole diameter is small.

Embodiment 3

[0036] A mucus type pore sealing agent mixed with graded particles, which is composed of the following components by weight: 6 parts of hydroxyethyl methylcellulose, 2 parts of sodium polyacrylate, 2 parts of gelatin, and 9 parts of graded rock powder , 0.04 parts of non-ionic polyacrylamide, 180 parts of water;

[0037] Among them, the mass ratio of the particle size of the graded particles is 5 to 3 mm: 3 to 1 mm: 1 to 0.4 mm: less than 0.4 mm=3.3:5.3:6:5.4.

[0038] The preparation and use method is the same as in Example 1.

[0039] The plugging agent of this embodiment is suitable for situations where the surrounding rock fractures of the borehole are well developed and the borehole diameter is relatively large.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com