A kind of environment-friendly fluorine-modified styrene-acrylic emulsion coating used in winter and preparation method thereof

A technology of styrene-acrylic emulsion and fluorine modification, which is applied in coating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

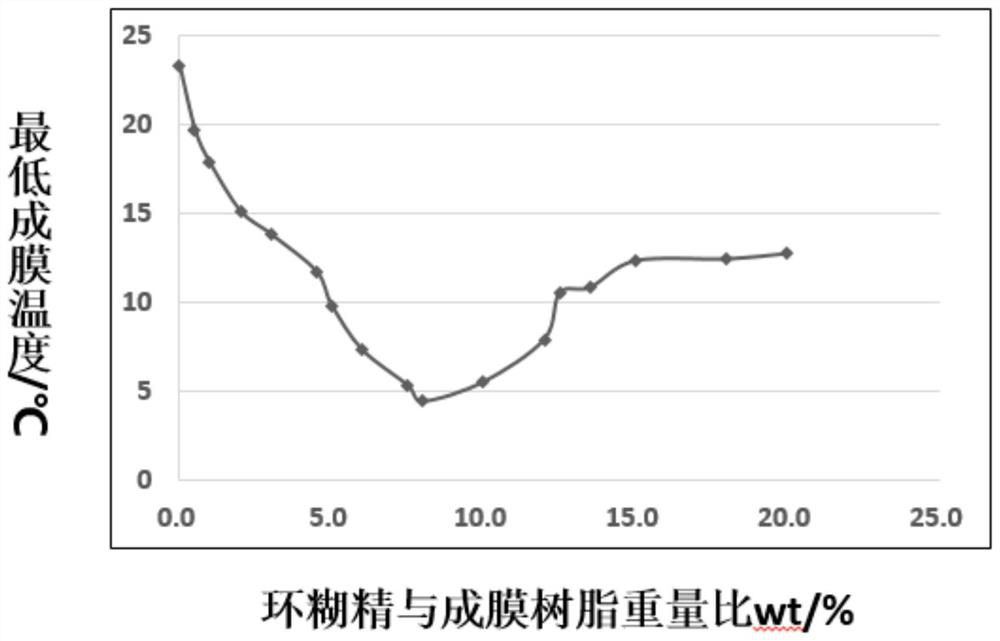

Image

Examples

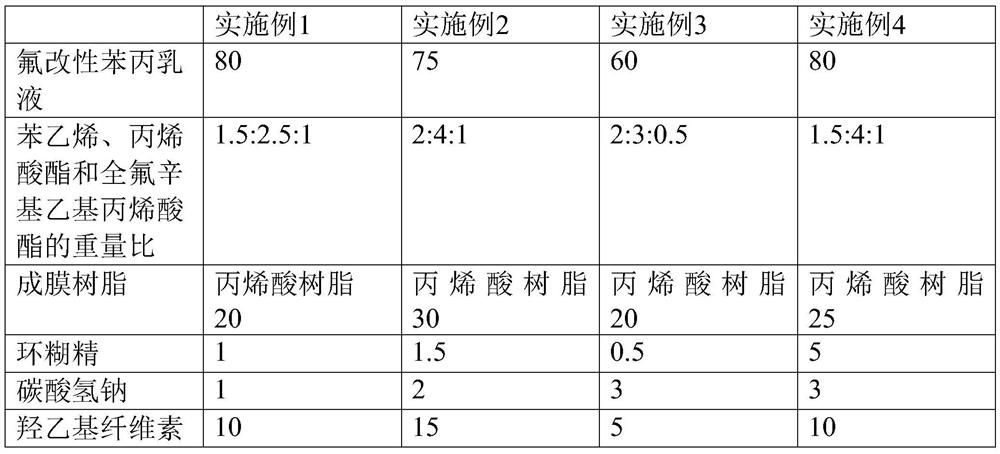

Embodiment 1-4

[0031] The fluorine-modified styrene-acrylic coatings of Examples 1-4 were prepared according to the following steps.

[0032] (1) Under the stirring condition of 1000 rpm, add emulsifier, leveling agent, drier, dispersant, defoamer, stabilizer to the water, stir for 20-30 minutes and then reduce the stirring speed to obtain a slurry, spare;

[0033] (2) Add fluorine-modified styrene-acrylic emulsion to the slurry obtained in step (1) successively under the stirring condition of 1000 rpm, film-forming resin, cyclodextrin, sodium bicarbonate, hydroxyethyl cellulose, and pH adjustment agent to adjust the pH value to 8-9 to obtain a slurry;

[0034] The fluorine-modified styrene-acrylic emulsion is obtained by emulsion copolymerization of styrene, acrylate and perfluorooctyl ethyl acrylate in a weight ratio of (1-3):(2-5):(0.5-2);

[0035] (3) Add diatomaceous earth, talcum powder, and heavy calcium carbonate to the slurry obtained in step (2) under stirring conditions of 500 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com