Method for preparing high-strength anti-radiation resin composite material

A resin composite material and radiation protection technology, which is applied in the field of radiation protection material preparation, can solve the problems of poor radiation protection performance, easy falling off of metal components, and easy breakage, etc., and achieves the effect of improving radiation protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

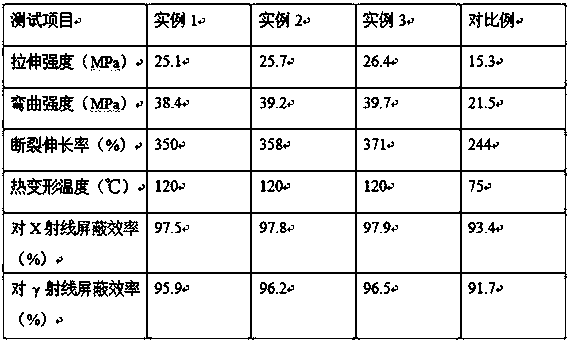

Examples

example 1

[0023]Put the rice husk and straw into the steam explosion tank at a mass ratio of 1:3, and deliver water vapor at a temperature of 260°C to the steam explosion tank until the pressure in the tank rises to 3MPa, seal the steam explosion tank, and let it stand at constant temperature and pressure After 30 minutes, open the mouth of the steam explosion tank, pour the product in the tank into a beaker, and cool naturally to room temperature to obtain the steam explosion product; pour 8% hydrochloric acid into the above beaker to impregnate the steam explosion product, and let it stand at room temperature After 30min, filter to obtain the filter cake, wash the filter cake with distilled water for 3 times to obtain the reaction product, in parts by weight, weigh 7 parts of the reaction product, 2 parts of citric acid crystal particles and 19 parts of chlorinated acid with a mass fraction of 10%. The sodium solution is put into a three-necked flask, and the three-necked flask is plac...

example 2

[0025] Put the rice husk and straw into the steam explosion tank at a mass ratio of 1:3, transport water vapor at a temperature of 270°C to the steam explosion tank, until the pressure in the tank rises to 4MPa, seal the steam explosion tank, and let it stand at constant temperature and pressure After 35 minutes, open the mouth of the steam explosion tank, pour the product in the tank into a beaker, and cool naturally to room temperature to obtain the steam explosion product; pour 9% hydrochloric acid into the above beaker to impregnate the steam explosion product, and let it stand at room temperature Filter cake after 35min, wash the filter cake with distilled water 4 times and make the reaction product, by weight, take 8 parts of reaction product, 2 parts of citric acid crystal particles and 20 parts of chlorinated acid with a mass fraction of 13%. The sodium solution is put into a three-necked flask, and the three-necked flask is placed in an ultrasonic oscillator and ultras...

example 3

[0027] Put the rice husk and straw into the steam explosion tank at a mass ratio of 1:3, and deliver water vapor at a temperature of 280°C to the steam explosion tank until the pressure in the tank rises to 5MPa, seal the steam explosion tank, and let it stand at constant temperature and pressure After 40 minutes, open the mouth of the steam explosion tank, pour the product in the tank into a beaker, and cool naturally to room temperature to obtain the steam explosion product; pour 10% hydrochloric acid into the above beaker to impregnate the steam explosion product, and let it stand at room temperature Filter cake after 40min, wash the filter cake with distilled water 5 times and make the reaction product, by weight, take 9 parts of reaction product, 3 parts of citric acid crystal particles and 22 parts of chlorinated acid with a mass fraction of 15%. The sodium solution is put into a three-necked flask, and the three-necked flask is placed in an ultrasonic oscillator and ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com