Livestock manure-based organic fertilizer and processing method thereof

A technology of livestock and poultry manure and processing methods, applied in the direction of organic fertilizers, organic fertilizer preparation, inorganic fertilizers, etc., can solve the problems that nutrients cannot be well utilized, the absorption rate of crops is not high, and the preparation methods are complicated. To achieve the effect of recycling, reducing the carbon-nitrogen ratio, and solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

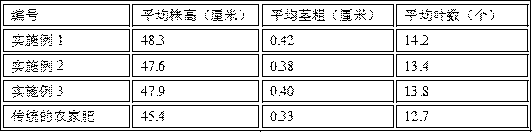

Examples

Embodiment 1

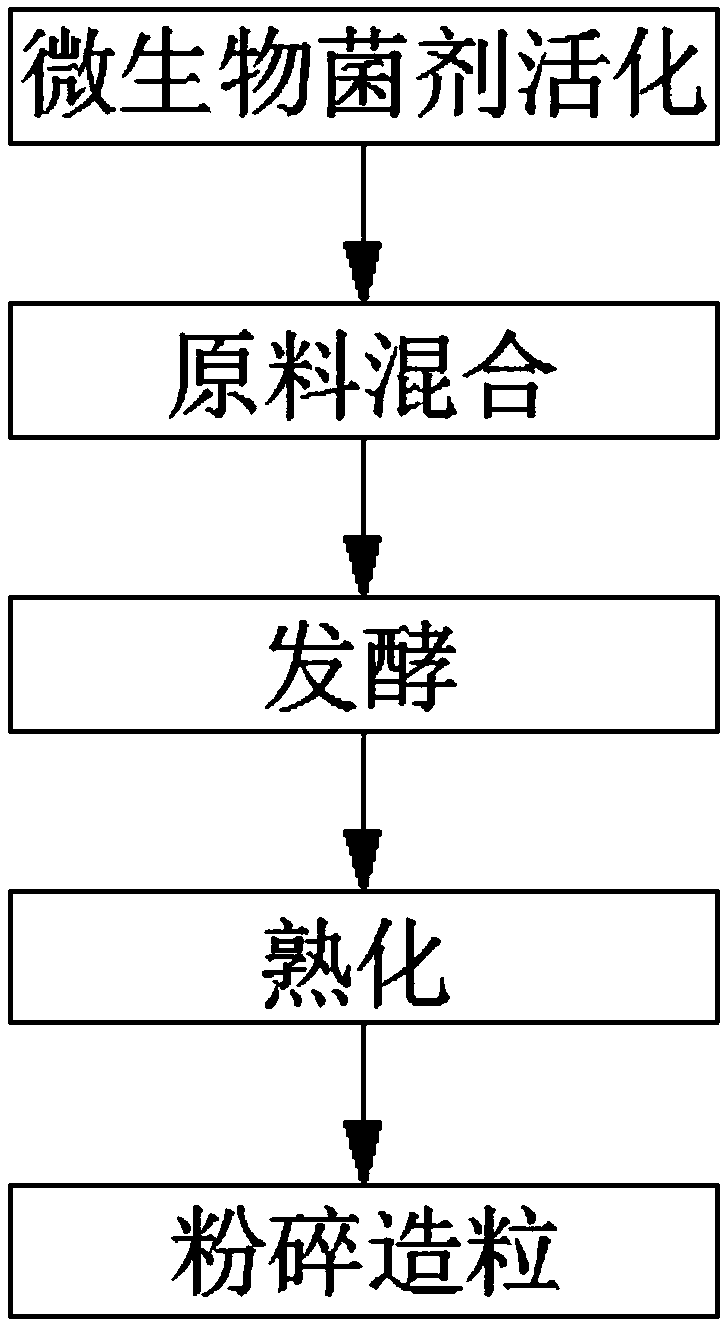

[0026] The processing method of the organic fertilizer based on livestock and poultry manure comprises the steps:

[0027] S1: Microbial agent activation: Stir the microbial agent, urea, molasses and water evenly, and let it stand for 13 hours. The amount of water used is 35 times the amount of the microbial agent;

[0028] S2: Mixing of raw materials: Mix livestock and poultry manure, bran, lime, silt, bentonite, inorganic nutrients and trace elements evenly, add the activated microbial agent in step S1, stir evenly, and then perform moisture detection to control the water content at 48%-58%, the method of adding the microbial agent is, in the process of stirring, use the spray device to spray evenly, the method of moisture detection is, the raw material is like mud when grasped by hand, and it can be loose when thrown on the ground;

[0029] S3: Fermentation: The mixed raw materials are distributed to the fermentation tank by belt conveyor and automatic distribution machine ...

Embodiment 2

[0034] The processing method of the organic fertilizer based on livestock and poultry manure comprises the steps:

[0035] S1: Microbial agent activation: Stir the microbial agent, urea, molasses and water evenly, and let it stand for 14 hours. The amount of water used is 40 times the amount of the microbial agent;

[0036] S2: Mixing of raw materials: Mix livestock and poultry manure, bran, lime, silt, bentonite, inorganic nutrients and trace elements evenly, add the activated microbial agent in step S1, stir evenly, and then perform moisture detection to control the water content at 48%-58%, the method of adding the microbial agent is, in the process of stirring, use the spray device to spray evenly, the method of moisture detection is, the raw material is like mud when grasped by hand, and it can be loose when thrown on the ground;

[0037] S3: Fermentation: The mixed raw materials are distributed to the fermentation tank by belt conveyor and automatic distribution machine ...

Embodiment 3

[0042] The processing method of the organic fertilizer based on livestock and poultry manure comprises the steps:

[0043] S1: Microbial agent activation: Stir the microbial agent, urea, molasses and water evenly, and let it stand for 12 hours. The amount of water used is 30 times the amount of the microbial agent;

[0044] S2: Mixing of raw materials: Mix livestock and poultry manure, bran, lime, silt, bentonite, inorganic nutrients and trace elements evenly, add the activated microbial agent in step S1, stir evenly, and then perform moisture detection to control the water content at 48%-58%, the method of adding the microbial agent is, in the process of stirring, use the spray device to spray evenly, the method of moisture detection is, the raw material is like mud when grasped by hand, and it can be loose when thrown on the ground;

[0045] S3: Fermentation: The mixed raw materials are distributed to the fermentation tank by belt conveyor and automatic distribution machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com