Sewage reuse purification system

A purification system and sewage purification technology, applied in water/sewage treatment, heating water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of limited water use range and insufficient cleanliness, and achieve improved scrubbing effect, Improvement of reuse rate and effect of impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as figure 1 , figure 2 As shown, a sewage reuse purification system includes a sewage purification device and a controller, and the sewage purification device includes a settling chamber 1 and a purification chamber 2;

[0039] The inside of the settling chamber 1 is provided with a filter chamber 3, the filter chamber 3 is provided with a first water inlet 4, the first water inlet 4 is provided with a sewage pipe 5, and the sewage pipe 5 runs through the top of the settling chamber 1 and is connected to the first water inlet 4, The side wall of the filter chamber 3 is provided with evenly distributed filter holes 6, the settling chamber 1 is connected to the inside of the filter chamber 3 through the filter holes 6, and a water outlet 7 is arranged below the settling chamber 1, and a water outlet pipe 8 is arranged on the water outlet 7. The other end of the water pipe 8 is connected to the clean room 2;

[0040] The upper part of the side wall of the purificat...

Embodiment 2

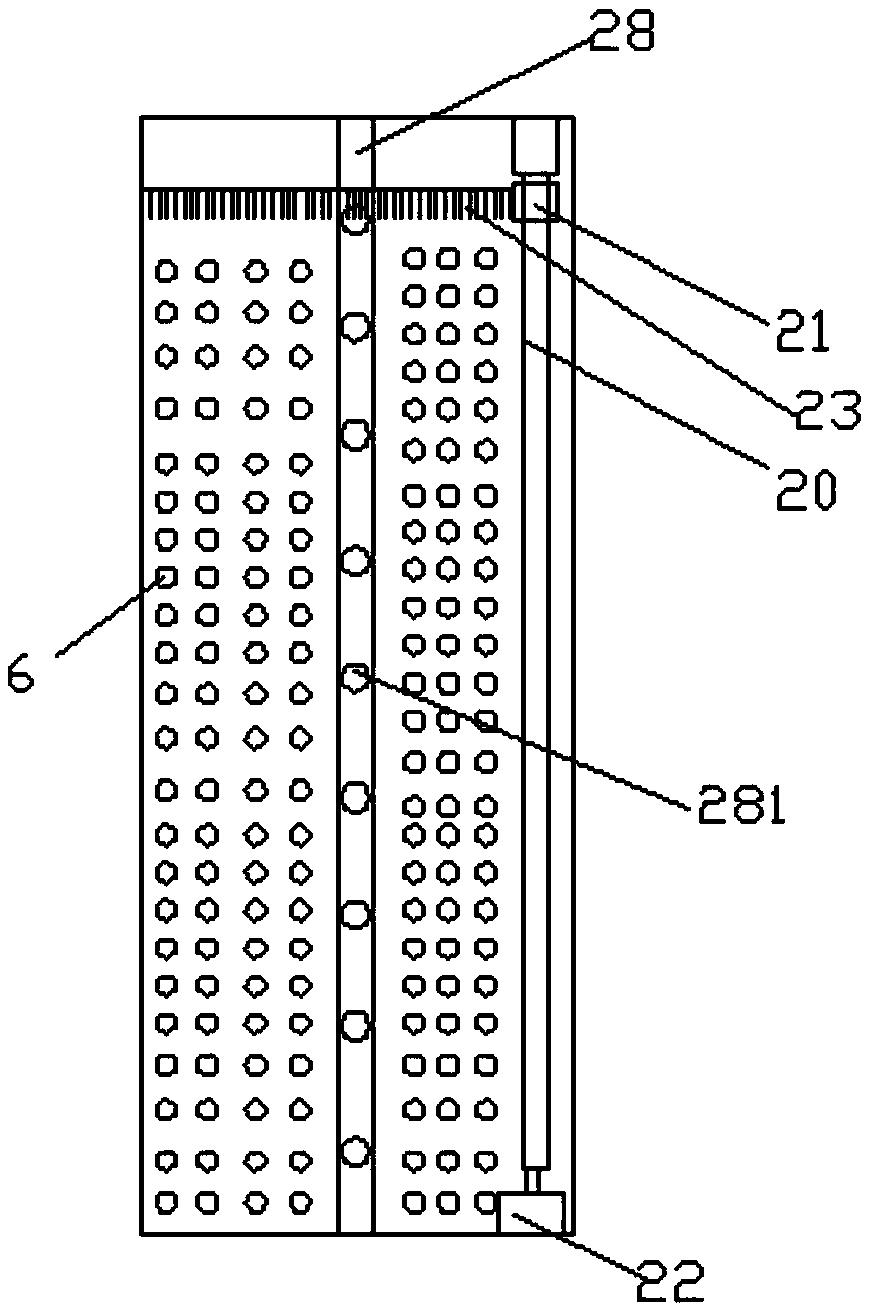

[0045] On the basis of the above examples, if image 3 As shown, both side walls of the filter chamber 3 are provided with a linear drive rod 20, a slide block 21 is arranged on the linear drive rod, and one end of the linear drive rod 20 is connected with a micro-motor 22, and the slide block 21 is provided with a dirt brush 23 , the linear drive rod 20 runs under the drive of the micro motor 22 to drive the dirt brush 23 to reciprocate, and the micro motor 22 is connected with the controller.

[0046] Filter chamber 3 sidewalls and bottom inner layer are provided with cleaning pipe 28, and cleaning pipe 28 is provided with spray hole 281, and filter chamber 3 is provided with the small hole corresponding to the size of water spray hole 281, and cleaning pipe 28 outside is provided with one deck. For reverse filter geotextiles, a first water pump 29 is provided in the settling chamber 1, and one end of the cleaning pipe 28 is connected to the first water pump 29; the first wa...

Embodiment 3

[0051] Such as figure 1 As shown, the impurity chamber 15 is separated with a side filter plate 30, and the filter plate 30 is provided with evenly distributed small holes. The filter plate 30 and the bottom of the impurity chamber 15 form a water storage chamber 51, and a second water pump is arranged in the water storage chamber 31. 31, the second water pump 31 is provided with a circulating water pipe 32, the circulating water pipe 32 passes through the bottom of the impurity chamber 15, and runs through the side wall of the settling chamber 1 to communicate with the settling chamber 3, and the circulating water pipe 32 is provided with an electromagnetic control valve 19;

[0052] One side of the impurity chamber 15 is provided with an impurity removal port 33, and the filter plate 30 is arranged obliquely in the impurity chamber 15, and the lower end is set at the impurity removal port 33;

[0053] The oblique filter plate 30 can be beneficial to get rid of the sediment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com