An efficient and environmentally friendly concrete preparation equipment

A kind of concrete and environmental protection technology, which is applied in the direction of clay preparation device, mixing operation control, mixing operation control device, etc., can solve the problems of explosion hazard of concrete mixing tank, insufficient mixing of concrete materials, long mixing time, etc., so as to shorten the mixing time, Reduced energy consumption and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

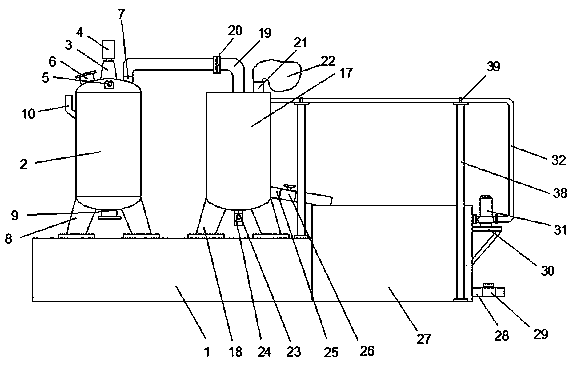

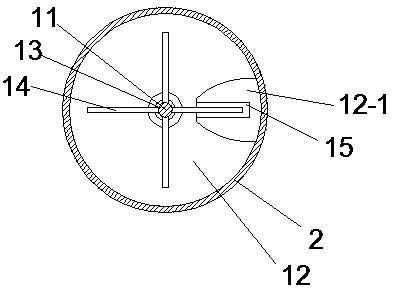

[0025] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention. The fixed connection, fixed arrangement, and fixed structure mentioned in this embodiment are all well-known technologies known to those skilled in the art, such as one-time concrete pouring, welding, and the like.

[0026] The induced draft fan mentioned in the present invention is adopted by Wuxi Xingao Machinery Equipment Co., Ltd., and the model is FC6-48A type dust exhaust centrifugal fan; the mentioned circulating water pump is manufactured by Shanghai Hongxing Pump Industry. Manufacturing Co., Ltd., the model is 40SG15-50 vertical pipeline pump; the induced draft fan, circulating wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com