Stainless steel slag dry magnetic separation device and process

A dry magnetic separation, stainless steel technology, applied in the field of metallurgy and mineral engineering, can solve the problems of tailings pond secondary pollution, long wet process, high production cost, shorten the production process, expand desulfurization efficiency, improve The effect of metal recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

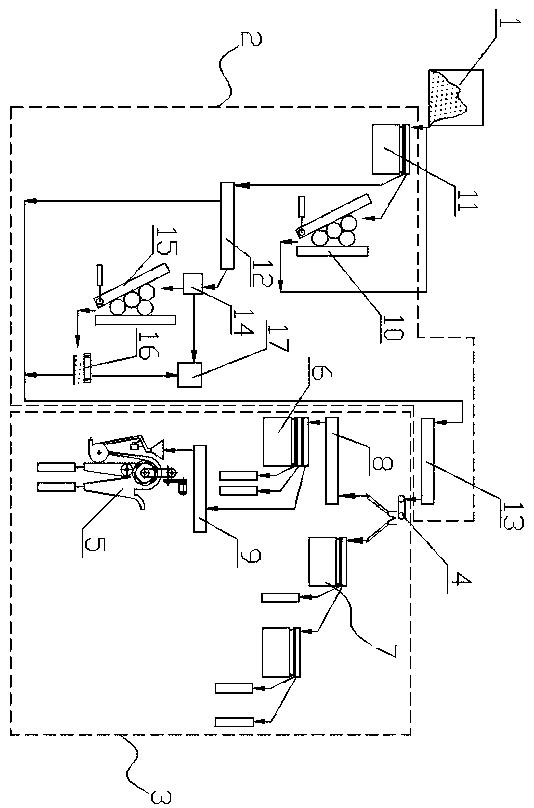

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0044] Such as figure 1 As shown, a dry type magnetic separation device for stainless steel slag includes a raw material bin 1 and a steel scrap collection device 17, and also includes a crushing and screening device 2 arranged under the raw material bin 1 and a magnetic separation device 3 communicated with the crushing and screening device 2. The magnetic separation device 3 includes a magnetic separation unit, a screening mechanism and an abrasive mechanism, the magnetic separation unit includes a dry drum magnetic separator 4 and a dry magnetic separator 5, and the screening mechanism includes a screening machine 6 and a vibrating screen group 7 , the abrasive mechanism includes a dry coarse grinding ball mill 8 and a dry fine grinding ball mill 9, a dry drum magnetic separator 4 is set under the crushing and screening device 2, and the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com