Surface modified polyarylether bone implant material containing phthalazinone biphenyl structure and preparation method thereof

A naphthalenone biphenyl and surface modification technology, which is used in pharmaceutical formulations, coatings, pharmaceutical sciences, etc., can solve the problems of poor surface coating stability, affecting the life of PEEK implants, and low biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The preparation method of PPEK and PPENK used in the following is the same as that of 'Wang Mingjing. Research on a new type of polyarylether eye with phthalazinone biphenyl structure [D]. Dalian: Dalian University of Technology, 2007'; the preparation of PPBES and PPBESK used in the following The method is the same as that of 'Xiao Lihong. Synthesis and properties of multi-component copolyaryl ethers containing heterogeneous biphenyl structure [D]. Dalian: Dalian University of Technology, 2008'. The physical and chemical properties of PPEK, PPEK, PPBES, and PPBESK used below are shown in Table 1:

[0066] Table 1 Physicochemical properties of PPEK, PPENK, PPBES, PPBESK

[0067]

[0068] The structural formula of PPENK is as follows:

[0069]

Embodiment 1

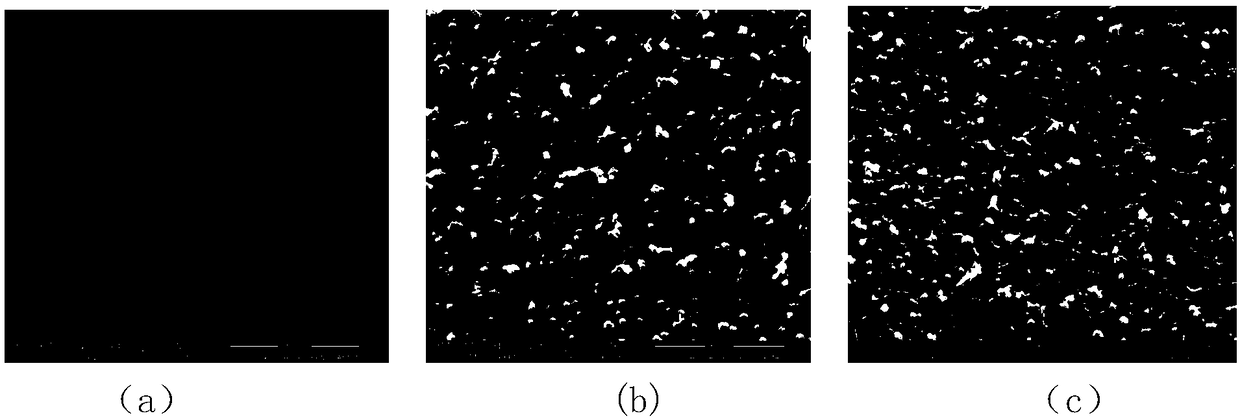

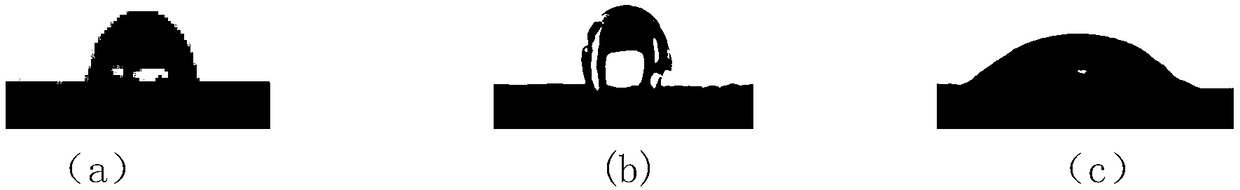

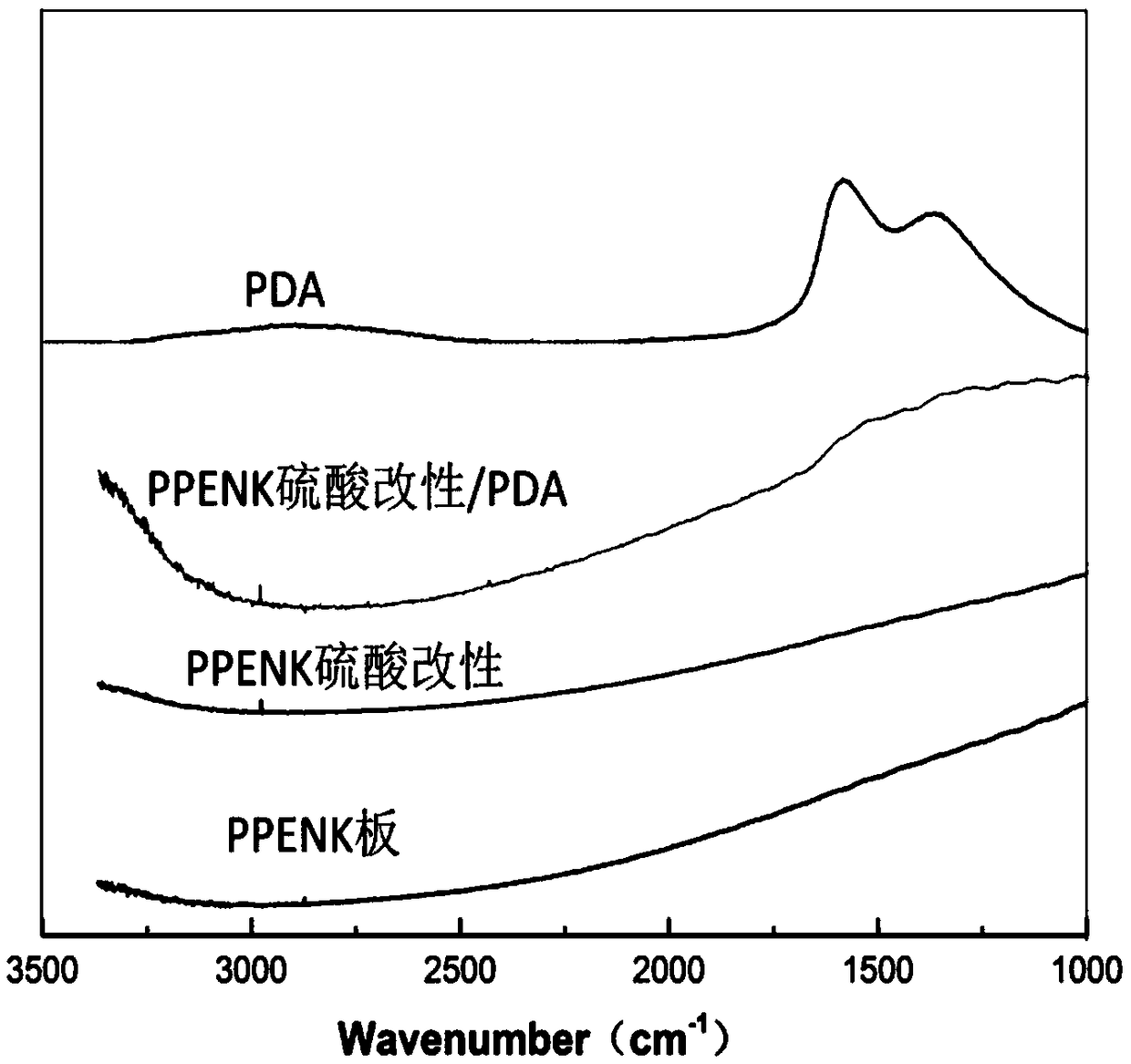

[0071] The first step is to prepare the three-dimensional surface of the PPENK sheet

[0072] Sonicate the PPENK sheet by immersing it in acetone for 10 minutes, immersing it in ethanol for 10 minutes, and immersing it in ultrapure water for 10 minutes. At room temperature (22-25°C), immerse about 0.13g of PPENK slices in concentrated sulfuric acid with a concentration of 96%. After 3 minutes, quickly take out the PPENK slices and place them in a mixture of ice and water at about 4°C for 30 minutes. Washed twice with deionized water, put into blast oven to dry after washing, and obtain PPENK sheet after three-dimensional surface modification.

[0073]In the second step, a polydopamine layer is deposited on the three-dimensional surface of the polyarylether ketone (PPENK) material by dopamine self-polymerization.

[0074] Tris aqueous solution was used as a buffer solution to prepare 10 mL of a dopamine solution with a concentration of 2 mg / mL, and the pH value was adjusted to...

Embodiment 2

[0077] The biomimetic mineralization modification of polydopamine-modified PPENK sheets with a three-dimensional surface was performed on bone-like apatite for 2 days, and the rest of the steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com