Multilayer straw substrate for rice hole tray dry nursery seedling and preparation method and application thereof

A technology for dry seedling raising and straw is applied to the field of multilayer substrates for dry seedling raising in rice plug trays and the field of preparation thereof, which can solve the problems of low utilization rate of straw and low seedling rate of rice seeds, and achieve excellent mechanical properties and strong mechanical properties. , the effect of neat emergence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

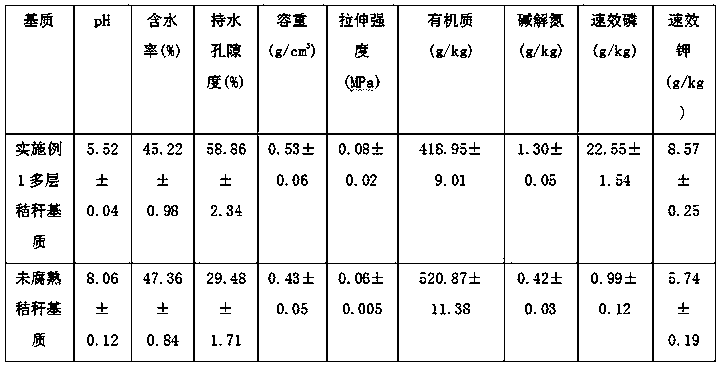

Embodiment 1

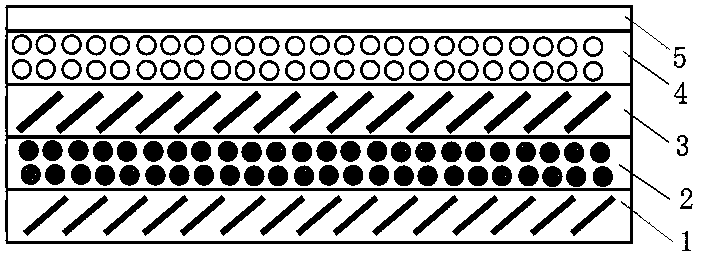

[0035] 1. Preparation of multilayer straw substrate

[0036] 1) The recovered crop stalks adjust the moisture content to 25%. After the straws are rubbed and crushed, they are prepared into short fiber straws with an average length of 2cm and long fiber straws with an average length of 6cm, for use;

[0037] 2) Mix the long straw fibers and short straw fibers obtained in step 1) with 1% cow dung water, and add 150 kg of cow dung water for every 75 kg of stalk fibers. The moisture content of the selected cow dung water is controlled at about 55%. ; The fully mixed materials are filled into a fermentation tank with a mechanical vent at the bottom for fermentation. 15kg of cow dung water with a concentration of 1% is replenished every day, and the pile is turned over every 7 days. When the fermentation is 20 days and 40 days, they are added separately 10kg long straw fiber or short straw fiber, turn the pile fully and evenly each time, keep the temperature error of each part of the fe...

Embodiment 2

[0056] Example 2 Preparation of multi-layer straw substrate

[0057] 1) The recovered crop stalks adjust the moisture content to 55%. After the straws are rubbed and crushed, they are prepared into short fiber straws with an average length of 3cm and long fiber straws with an average length of 5cm, for use;

[0058] 2) Mix the long straw fibers and short straw fibers obtained in step 1) with the sheep manure water with a concentration of 3%, and add 150kg of sheep manure water for every 75kg of straw fibers. The moisture content of the selected cow manure water is controlled at about 60%. ; The fully mixed materials are filled into a fermentation tank with a mechanical vent at the bottom for fermentation. 15kg of sheep dung water with a concentration of 3% is added every day, and the pile is turned over every 7 days. When the fermentation is 20 days and 40 days, they are added separately 10kg long straw fiber or short straw fiber, turn the pile fully and evenly each time, keep the ...

Embodiment 3

[0069] 1) The recovered crop stalks adjust the moisture content to 75%. After the straws are rubbed and crushed, they are prepared into short fiber straws with an average length of 4cm and long fiber straws with an average length of 8cm, for use;

[0070] 2) Mix the long straw fiber and short straw fiber obtained in step 1) with 5% pig manure water, and add 150kg pig manure water for every 75kg of straw fiber. The moisture content of the selected pig manure water should be controlled at about 75%. ; The fully mixed materials are filled into a fermentation tank with a mechanical vent at the bottom to carry out the fermentation process. 15kg of pig manure water with a concentration of 5% is added every day, and the pile is turned over every 7 days. When the fermentation is 20 days and 40 days, they are added separately 10kg long straw fiber or short straw fiber, turn the pile fully and evenly each time, keep the temperature error of each part of the fermentation tank within 5℃ after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com