Dispersible flocculant, preparation method and application thereof

A flocculant and dispersive technology, applied in the field of dispersive flocculant and its preparation, can solve the problems of reducing the apparent viscosity of the dispersion system and forming gel, so as to improve the solubility and relative molecular weight, and reduce the excessive heat of reaction , Reduce the effect of cross-linking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

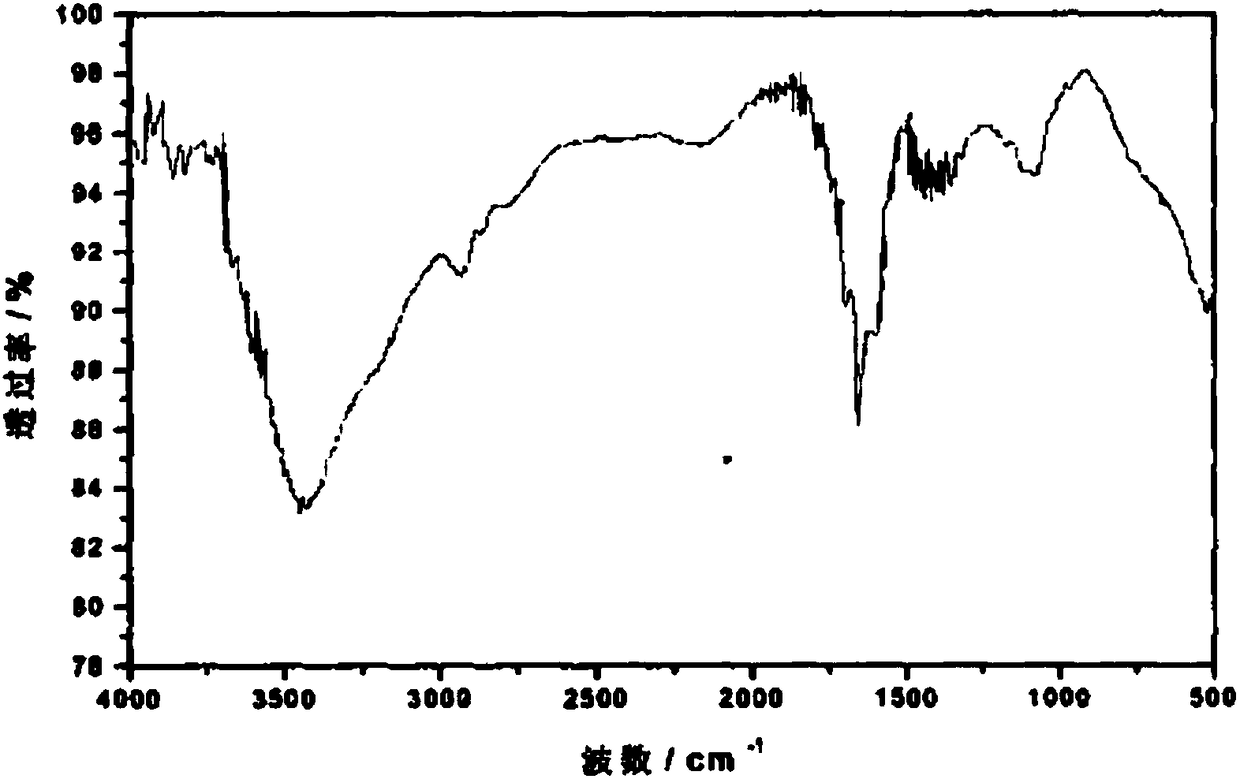

Image

Examples

Embodiment 1

[0033] 1. Using the water dispersion polymerization method, add acrylamide (AM) monomer and dimethyl diallyl ammonium chloride (DMDAAC ) monomer, polydimethyldiallylammonium chloride (PDMDAAC) as a dispersant, inorganic salt (NH 4 ) 2 SO 4 and NaCl, make it dissolve completely with deionized water, and ensure that the mass percentage of AM monomer and DMDAAC monomer in the final reaction system is 18%, and n(DMDAAC):n(AM)=15: 85 (mol / mol) (i.e. the ratio of the amount of substance of DMDAAC monomer and AM monomer is 15:85); The mass percentage that dispersant PDMDAAC accounts for the sum of AM monomer and DMDAAC monomer is 3.5%; (NH 4 ) 2 SO 4 The mass percentage in the final reaction system is 20%; the mass percentage of NaCl in the final reaction system is 0.5%, the resulting solution is placed in a 55°C constant temperature water bath and stirred, and the pH value of the reaction system is adjusted to be equal to 6 , after 20 minutes of deoxygenation by nitrogen gas, t...

Embodiment 2

[0038] Except changing the mass percent of AM monomer and DMDAAC monomer and in the final reaction system is 15%, repeat the step of embodiment 1, the relative molecular mass that obtains the CPAM polymkeric substance in the CPAM dispersion is 1.29 * 10 7 , the apparent viscosity of the system is 318.19mPa·s.

Embodiment 3

[0040] In addition to changing n(DMDAAC):n(AM)=20:80 (mol / mol) in the reaction system (i.e. the ratio of the amount of substance of DMDAAC monomer and AM monomer is 20:80), repeat the process of Example 1 step, the result is that the relative molecular mass of the CPAM polymer in the CPAM dispersion is 1.31×10 7 , the apparent viscosity of the system is 325.5mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com