Topology shape design method for partition machining track on curved surface based on vector field

A technology of processing trajectory and design method, applied in metal processing equipment, comprehensive factory control, manufacturing tools, etc., to achieve the effect of improving stability

Active Publication Date: 2019-02-19

DALIAN UNIV OF TECH

View PDF6 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

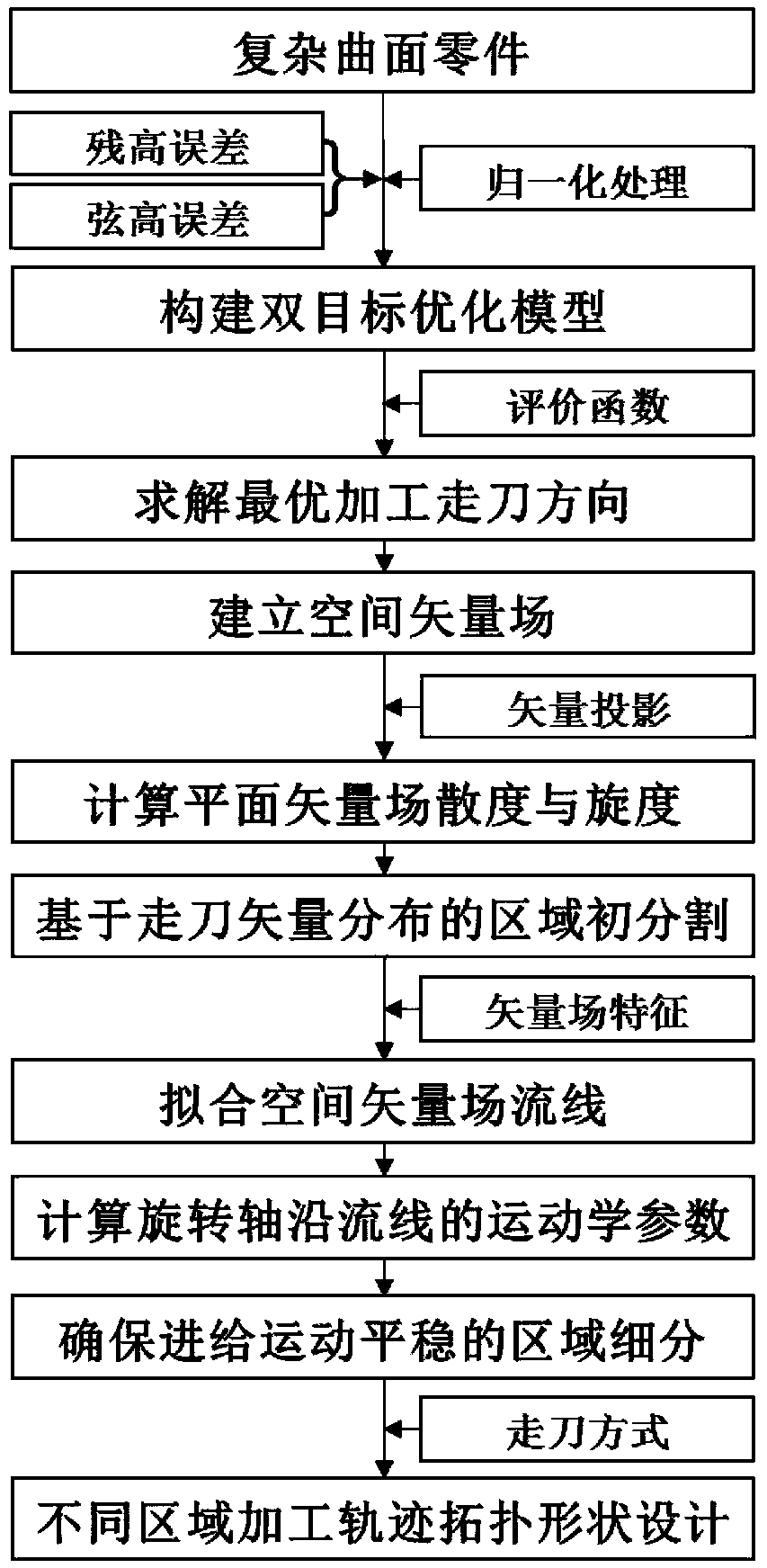

This method aims at the problems of local error out-of-tolerance and significant cutting vibration caused by the lack of comprehensive consideration of the tool-feeding mode and feed motion stability in the processing area division and trajectory planning in the process of partitioning complex curved surfaces. The tool-feed vector field of error cooperative constraints realizes the initial segmentation of the processing area based on the distribution of the tool-feed vector and the subdivision of the processing area to ensure the smooth feed motion. According to the partition results, the topological shape design of the complex surface parts partition machining trajectory is finally completed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

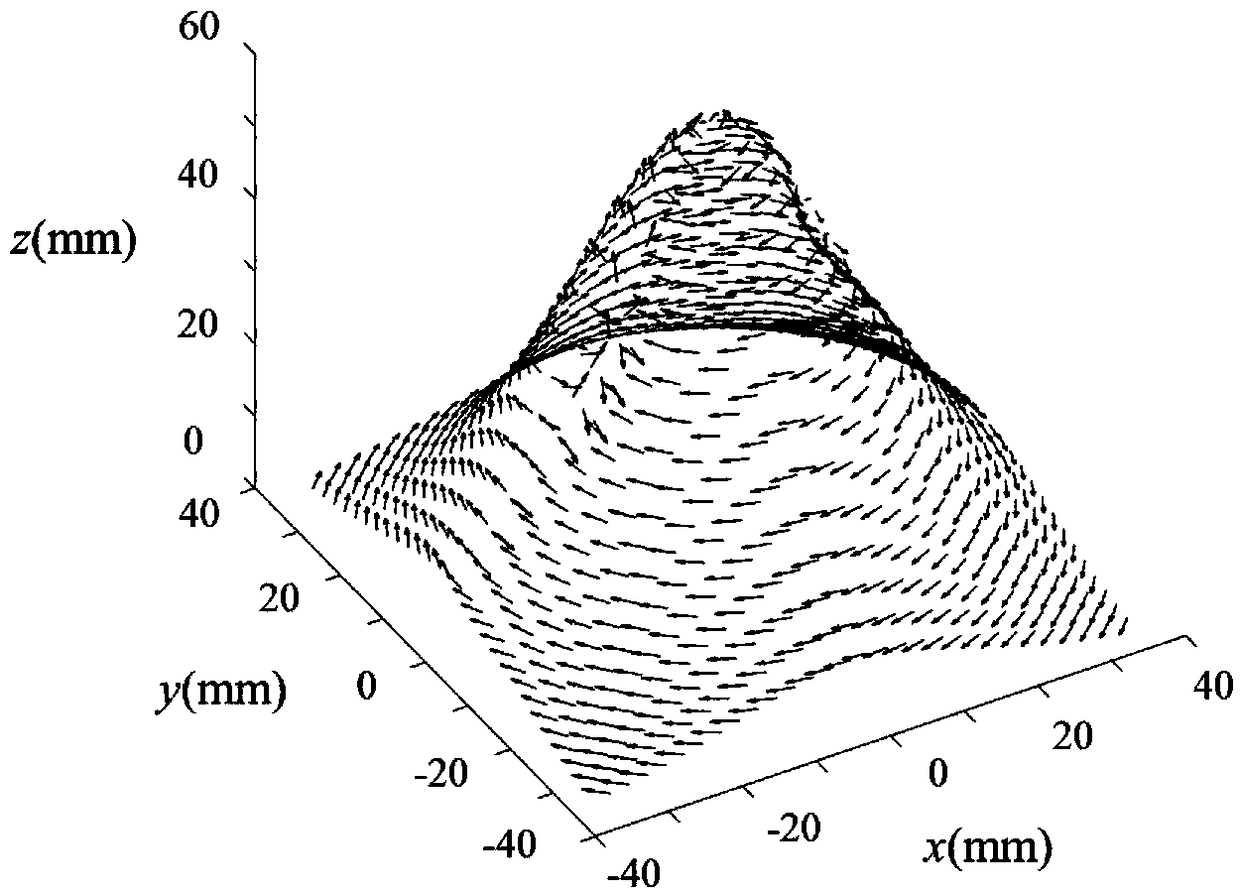

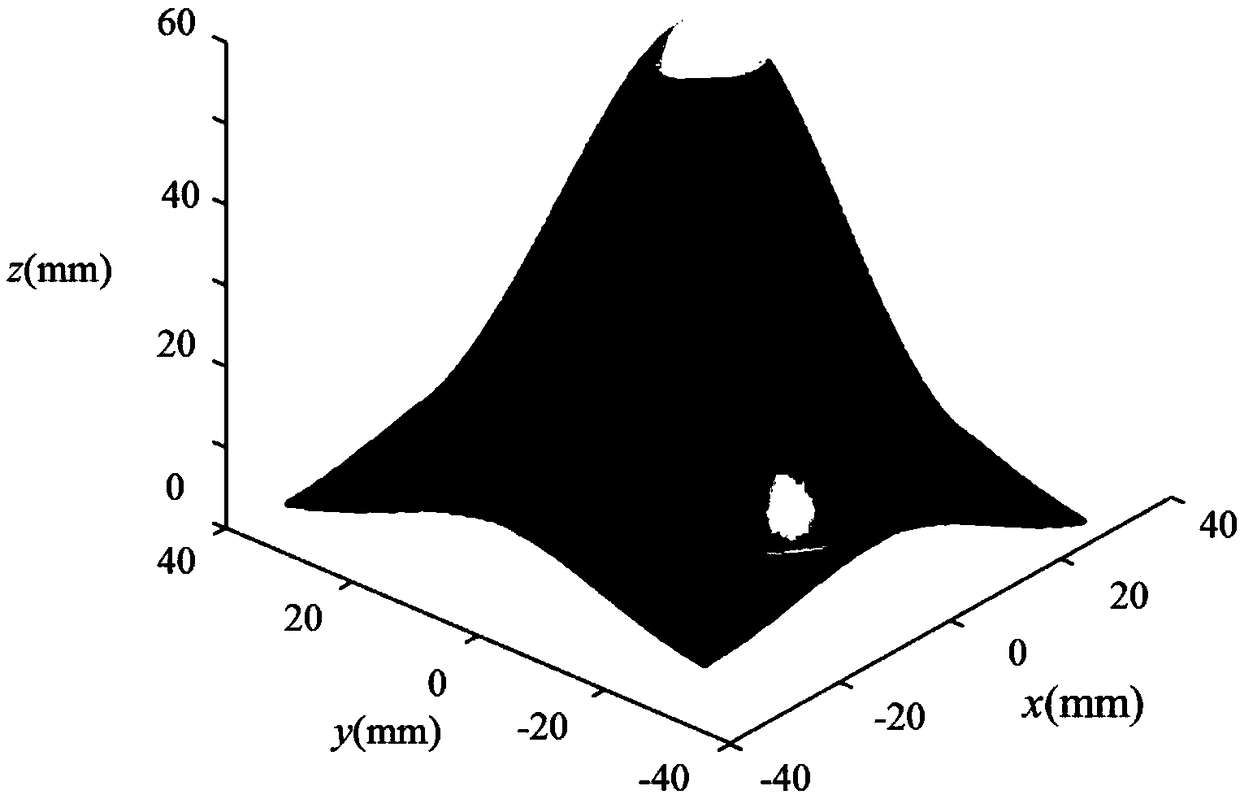

The invention discloses Topology shape design method for partition machining track on curved surface based on vector field, and belongs to the technical field of high precision and high efficient milling machining of complex curved parts, and relates to a topology shape design method for partition machining track on curved surface based on vector field. The method comprises the steps of: establishing a feeding vector field with a cooperation constraint of a chord height error and a residual error, constructing a normalized dual target optimization model with two types of error, solving optimalfeeding direction of each point through an evaluation function, and establishing a space vector field; calculating a divergence and a rotation of a plane vector field after projection, and realizinginitial segmentation of the machining region according to whether the divergence and the rotation of the plane vector field are zero or not; analyzing different vector field features, fitting spatialvector field streamlines, calculating motion parameters of feeding motions of a machine tool rotating shaft along deformation lines, and completing machining region partition according to whether theparameters are mutated or not; and realizing the topology shape design of partition machining track on curved surface in combination with a feeding mode. The topology shape design method for the partition machining track on the curved surface based on the vector field is suitable for complex curved surface partition machining, can reduce machining errors, and improves motion smoothness of feeding.

Description

technical field The invention belongs to the technical field of high-precision and high-efficiency milling processing of complex curved surface parts, and relates to a vector field-based method for designing the topological shape of curved surface partition processing tracks. Background technique At present, the development of aerospace, energy power, automobile and ship and other fields puts forward extremely high requirements on the machining accuracy of complex curved surface parts. The traditional method of unified process global machining is less applicable, which may easily lead to uneven error distribution and local out-of-tolerance , it is difficult to apply to high-precision machining of complex curved surface parts. In order to meet the processing requirements of such parts, the partition processing method is often used to divide the complex surface into multiple processing areas, and carry out appropriate processing trajectory and processing technology planning fo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G05B19/19B23C3/00

CPCG05B19/19B23C3/00G05B2219/35167G05B2219/37355G05B19/4166G05B19/402

Inventor 马建伟贾振元鲁晓姜文文赵孝轩刘巍司立坤

Owner DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com