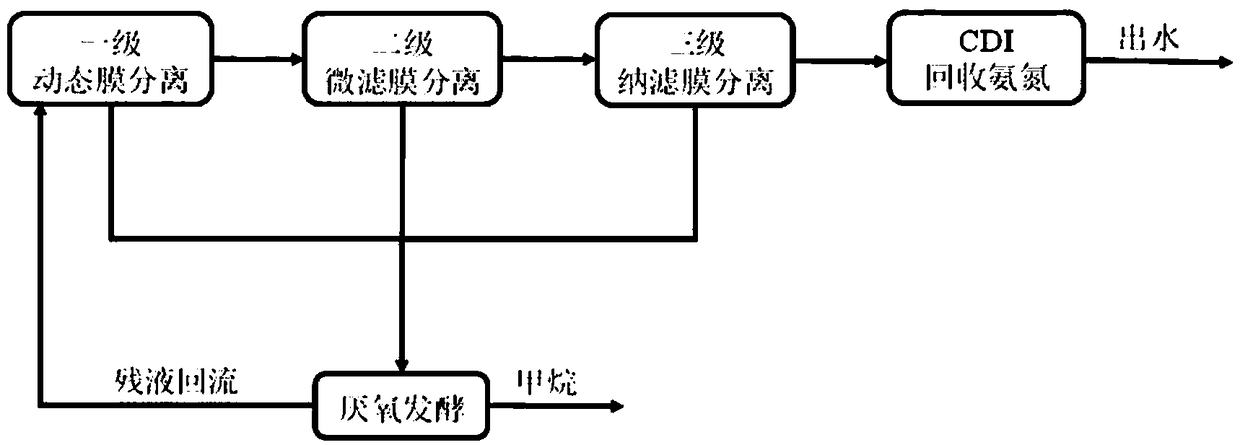

Sewage disposal and energy recovery method based on three-stage membrane separation technology

A technology for sewage treatment and energy recovery, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of easy clogging of separation membrane, limited treatment effect and high treatment load , to achieve the effect of realizing reuse, realizing efficient utilization, and reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for sewage treatment and energy recovery based on three-stage membrane separation technology, comprising the steps of:

[0023] (1) The raw sewage (average COD is 396.8mg / L, ammonia nitrogen concentration is 44.83mg / L) is sequentially passed through the first-stage dynamic membrane reactor, the second-stage microfiltration membrane reactor and the third-stage nanofiltration membrane reactor for solid-liquid separation. Separation, wherein, the first-stage dynamic membrane reactor uses 250-mesh polyester mesh with a thickness of 0.8mm as the base membrane, and after the sewage enters the first-stage dynamic membrane reactor, 50mg / L polyferric chloride is used as a coagulant to assist the coagulation and sedimentation of organic matter; the second-stage microfiltration membrane reactor uses PVDF microfiltration membrane with a pore size of 0.22 μm as the base membrane, and the sewage is automatically dosed after entering the second-stage microfiltration membrane ...

Embodiment 2

[0026] A method for sewage treatment and energy recovery based on three-stage membrane separation technology, comprising the steps of:

[0027] (1) The raw sewage (average COD is 396.8mg / L, ammonia nitrogen concentration is 44.83mg / L) is sequentially passed through the first-stage dynamic membrane reactor, the second-stage microfiltration membrane reactor and the third-stage nanofiltration membrane reactor for solid-liquid separation. Separation, wherein, the first-stage dynamic membrane reactor uses 800-mesh polyester mesh with a thickness of 0.8mm as the base membrane, and after the sewage enters the first-stage dynamic membrane reactor, 50mg / L polymerized ferric chloride is used as a coagulant to assist the coagulation and sedimentation of organic matter; the second-stage microfiltration membrane reactor uses a PVDF microfiltration membrane with a pore size of 0.50 μm as the base membrane, and the sewage is automatically dosed after entering the second-stage microfiltration...

Embodiment 3

[0030] A method for sewage treatment and energy recovery based on three-stage membrane separation technology, comprising the steps of:

[0031](1) The raw sewage (average COD is 396.8mg / L, ammonia nitrogen concentration is 44.83mg / L) is sequentially passed through the first-stage dynamic membrane reactor, the second-stage microfiltration membrane reactor and the third-stage nanofiltration membrane reactor for solid-liquid separation. Separation, wherein, the first-stage dynamic membrane reactor uses 450-mesh polyester mesh with a thickness of 0.8mm as the base membrane, and after the sewage enters the first-stage dynamic membrane reactor, 50mg / L polymerized ferric chloride is used as a coagulant to assist the coagulation and sedimentation of organic matter; the second-stage microfiltration membrane reactor uses a PVDF microfiltration membrane with a pore size of 0.11 μm as the base membrane, and the sewage is automatically dosed after entering the second-stage microfiltration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com