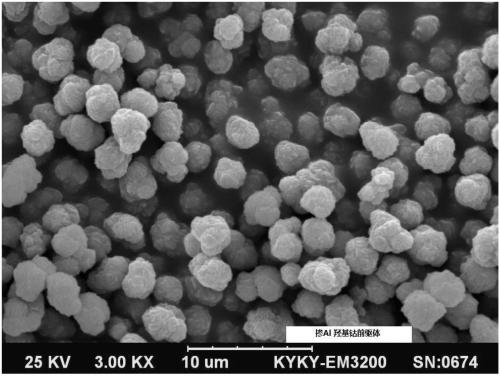

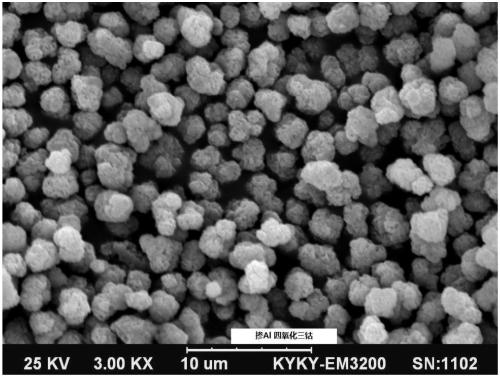

Preparation method of small-particle-size uniform-aluminum-doped spherical tricobalt tetraoxide

A technology with small particle size of cobalt tetroxide, which is applied in cobalt oxide/cobalt hydroxide, electrochemical generators, structural parts, etc., and can solve the problems of poor sphericity, small tap density, and low tap density of doped cobalt tetroxide, etc. Achieve the effects of narrow laser particle size distribution, guaranteed response time, and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. To 15M 3 Pour high-concentration cobalt sulfate into the preparation tank, add water to prepare a cobalt salt solution with a metal ion concentration of 80g / L, weigh 20.4kg aluminum sulfate octadecanoate and 12kg complexing agent disodium EDTA and add it to the cobalt sulfate solution. The mass ratio of ions, EDTA and cobalt ions is 0.0014:0.01:1 to obtain a cobalt-aluminum mixed salt complex solution.

[0024] 2. Inject 2.5M into the reactor 3 Use pure water as the bottom liquid, turn on the stirring, raise the temperature to 75°C, blow in air, and the air flow rate is 30m 3 / h, adding a small amount of sodium hydroxide solution with a concentration of 160g / L to adjust the pH to 10.9;

[0025] 3. Add the cobalt-aluminum mixed salt complex solution configured in step 1 and the sodium hydroxide solution with a concentration of 160g / L into the reaction kettle at the same time under stirring, and the flow rate of the cobalt-aluminum mixed salt complex solution is 150L...

Embodiment 2

[0030] 1. To 15M 3 Pour high-concentration cobalt chloride into the preparation tank, add water to prepare a cobalt salt solution with a metal ion concentration of 100g / L, weigh 92.5kg of aluminum chloride hexahydrate and 18kg of complexing agent disodium EDTA and add them to the cobalt chloride solution , the mass ratio of aluminum ions, EDTA and cobalt ions is 0.007:0.012:1 to obtain a cobalt-aluminum mixed salt complex solution.

[0031] 2. Inject 2.5M into the reactor 3 Pure water is used as the bottom liquid, start stirring, heat up to 80°C, blow in air, the air flow rate is 38m 3 / h, adding a small amount of sodium hydroxide solution with a concentration of 280g / L to adjust the pH to 10.6;

[0032] 3. Under stirring, add the cobalt-aluminum mixed salt complex solution configured in step 1 and the sodium hydroxide solution with a concentration of 280g / L into the reaction kettle at the same time for precipitation reaction, and the flow rate of the cobalt-aluminum mixed s...

Embodiment 3

[0037] 1. To 15M 3 Pour high-concentration cobalt nitrate into the preparation tank, add water to prepare a cobalt salt solution with a metal ion concentration of 120g / L, weigh 350.1kg of aluminum sulfate nonahydrate and 12kg of complexing agent disodium EDTA and add them to the cobalt nitrate solution, and the aluminum ions , The mass ratio of EDTA to cobalt ions is 0.014:0.015:1 to obtain a cobalt-aluminum mixed salt complex solution.

[0038] 2. Inject 2.5M into the reactor 3 Use pure water as the bottom liquid, turn on the stirring, raise the temperature to 85°C, blow in air, and the air flow rate is 42m 3 / h, adding a small amount of sodium hydroxide solution with a concentration of 400g / L to adjust the pH to 10.3;

[0039] 3. Under stirring, add the cobalt-aluminum mixed salt complex solution configured in step 1 and the sodium hydroxide solution with a concentration of 400g / L into the reaction kettle at the same time for precipitation reaction, and the flow rate of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com