Flame-retardant broadband high-power composite absorbing material

A composite wave-absorbing material and wide-band technology, which is applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of low flame retardancy, poor aesthetics of darkrooms, and difficult to exceed 40%. , to achieve the effect of solving labor-intensive and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Manufacture of absorbing material base material and housing triangular plate

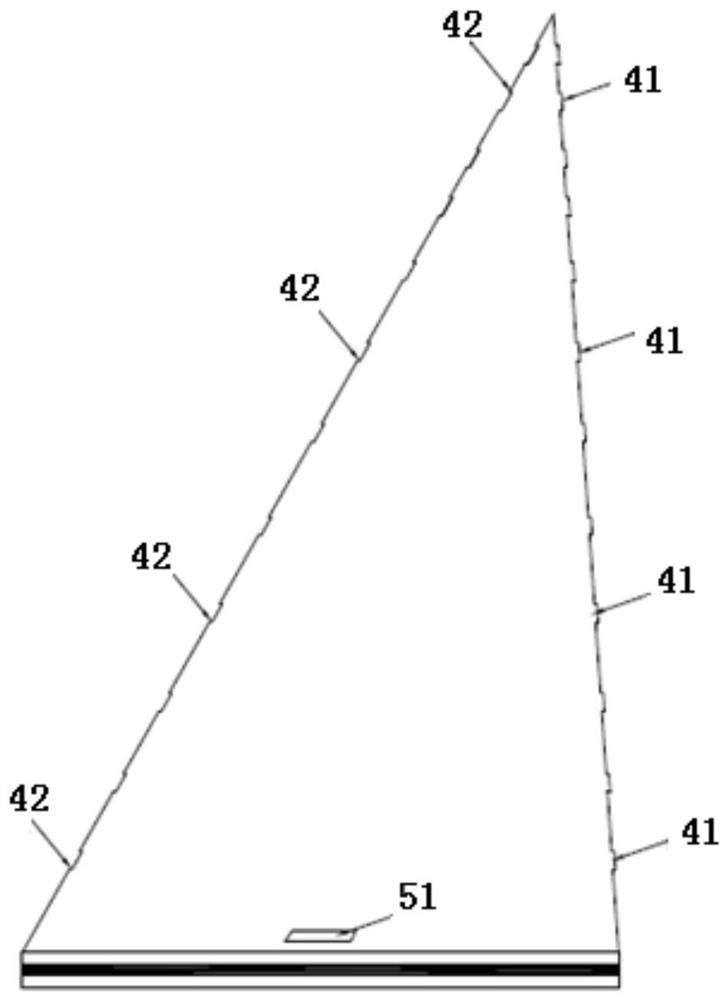

[0018] First, apply a layer of Hunter HT-8200 glue on the surface of two fireproof quartz plates with a thickness of 0.5mm, and place a conductive polyester film with a thickness of 0.2mm between the glued surfaces of the two fireproof quartz plates. The composite material is then placed in a flat-bed heat press for heat-compression curing. The pressure is between 5.0MPa and 8.0MPa, the temperature is 80°C, and the curing time is 20 minutes to form a flame-retardant wave-absorbing substrate (see figure 1 ), consisting of a composite layer structure of flame retardant layer 2 / conductive film 1 / flame retardant layer 1, the composite substrate is transferred to a flat die-cutting machine and cut into a triangular pyramid surface substrate and a square bottom substrate, the corner Conical substrate structure such as figure 2 , the two hypotenuses of the triangle have assembly convex ...

Embodiment 2

[0019] Example 2 Manufacture of the core shell of the absorbing material and filling it with absorbing particles

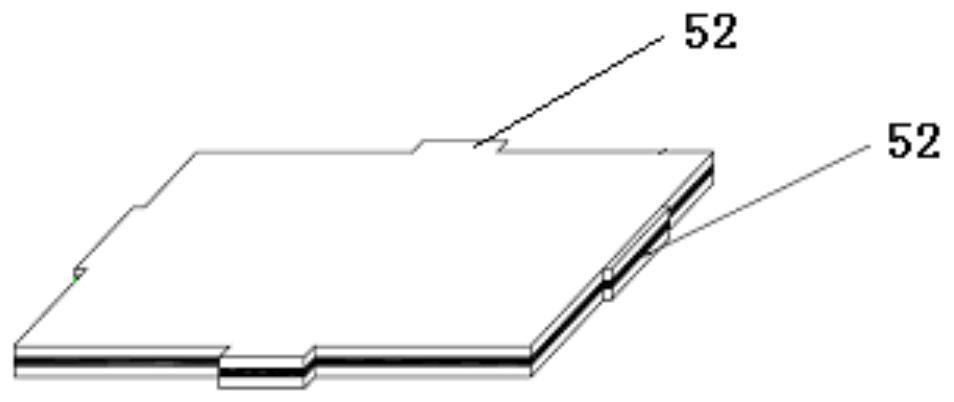

[0020] First, apply a layer of Hunter HT-8200 glue on the surface of two pieces of fireproof highland barley paper with a thickness of 0.2mm, and place a conductive polyester film with a thickness of 0.2mm between the glued surfaces of the two pieces of fireproof highland barley paper. The composite material is then placed in a flat-bed heat press for heat-compression curing. The pressure is between 5.0MPa and 8.0MPa, the temperature is 60°C, and the curing time is 30 minutes to form a flame-retardant wave-absorbing substrate. Transfer the composite substrate to a flat die-cutting machine and cut it into triangles, with a self-locking bottom structure on the bottom edge, see Figure 4 , Figure 5 . The inner core shell is brushed and assembled into a three-dimensional triangular cone, and the conductive flame-resistant polystyrene balls are filled inside the tr...

Embodiment 3

[0021] Example 3 Composition of Flame Retardant Wave Absorbing Material

[0022] Assemble the outer shell substrate with concave-convex grooves into the outer shell 6 of the three-dimensional triangular pyramid, fill the inner core 7 inside the outer shell 6, stick firmly with fireproof glue between the inner core 7 and the outer shell, and finally the inner core The self-locking bottom is sealed with an outer casing bottom plate to prevent the wave-absorbing filling ball 8 from running out of the material. its structure see Image 6 .

[0023] The flame retardant type produced by the present invention is called pyramid absorbing material, because its flame retardant layer is a fireproof quartz plate, and the fireproof barley paper is used as heat insulation and fireproof material for high-energy lithium battery packs, and its flame retardant grade belongs to A1 grade. In addition, the internal filling of the conduction resistance flame styrene balls will expand in volume wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com