Solution active-crystallizing device for absorption-type chemical energy storage

A chemical energy storage and crystallization device technology, applied in the direction of solution crystallization, heat exchange cooling crystallization, etc., can solve the problems of deviation from the design operating conditions, work cannot be carried out, and crystals cannot be dissolved, so as to optimize the overall structure and operating efficiency, reduce The amount of crystallization and the effect of promoting rapid crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

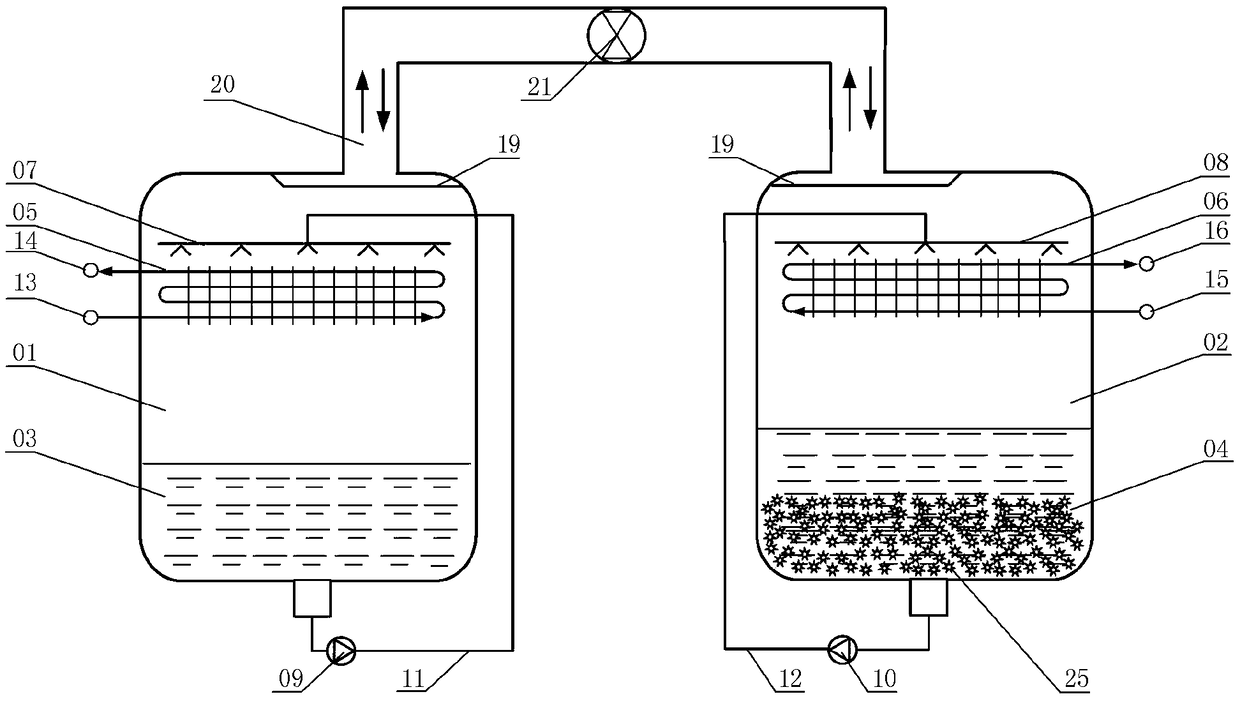

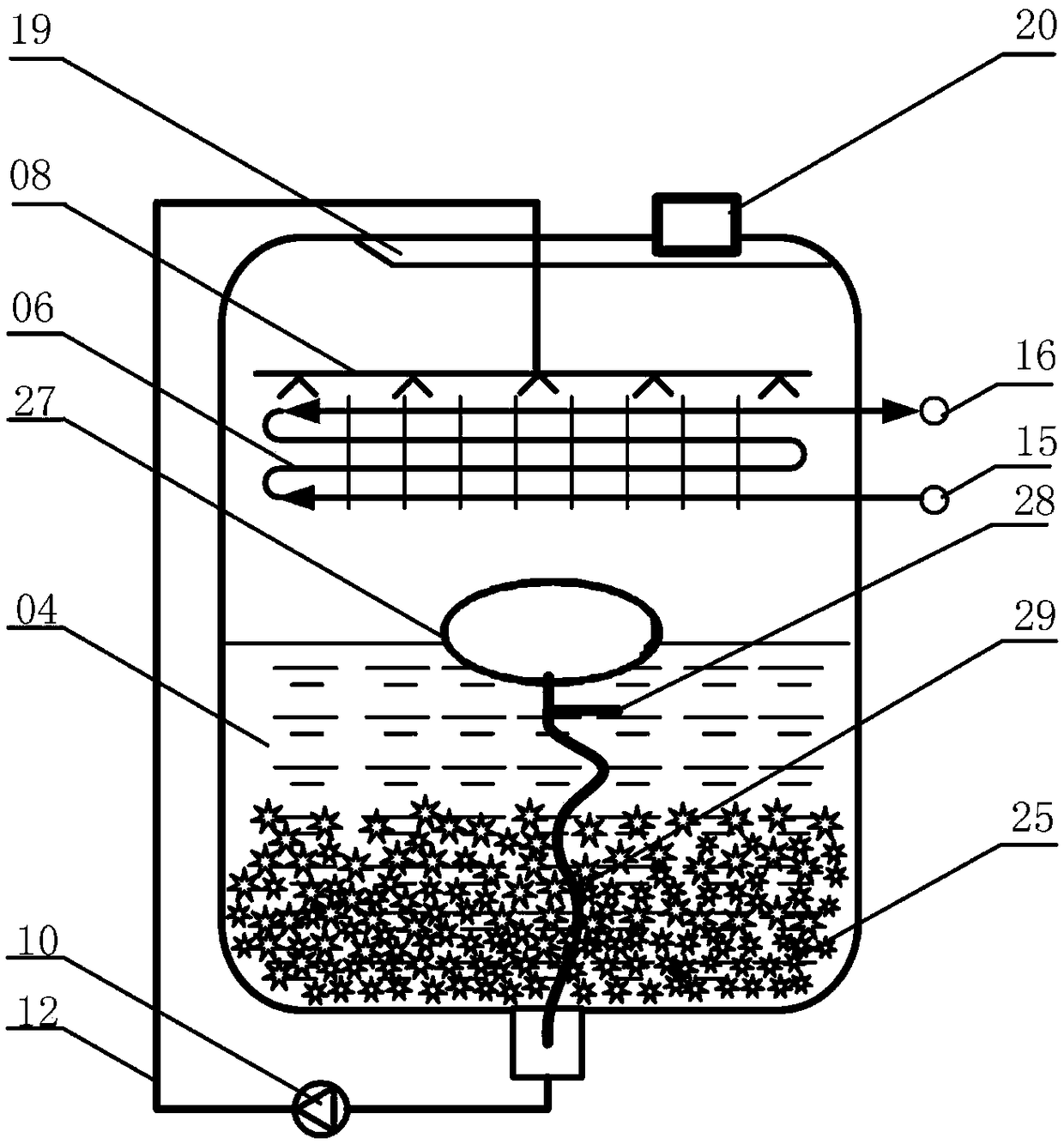

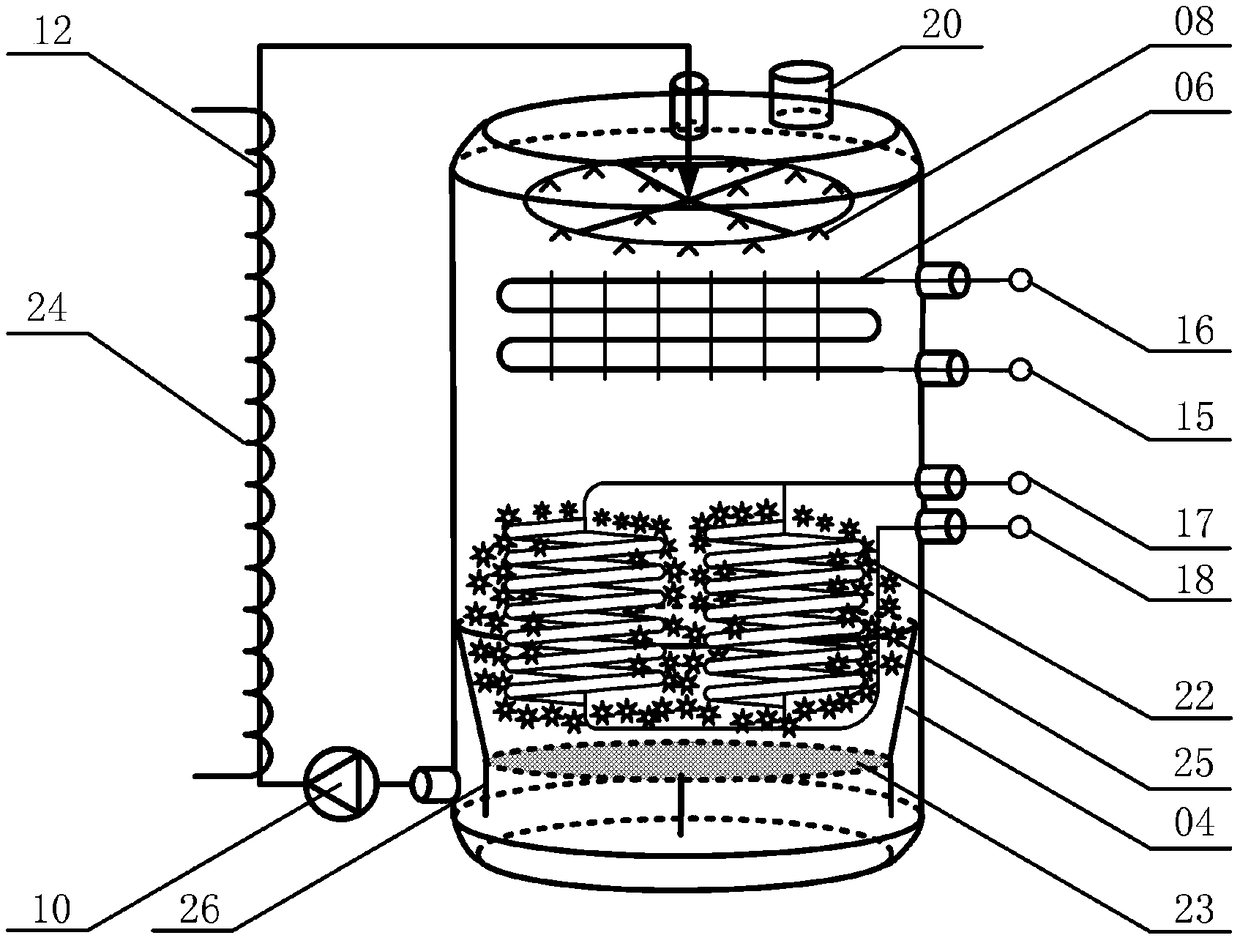

[0033] The specific implementation of the active crystallization process and energy release process of the absorption energy storage device described in this patent is as follows:

Embodiment approach 1

[0034] Implementation Mode 1: Active Crystallization Energy Storage Process

[0035] Under the set vacuum pressure and heating temperature conditions, the concentration of solution 04 will reach the limit value. When heating continues, the absorbent in the solution will crystallize on the vertical wall and bottom of the tank with lower temperature. Accumulation occurs in the dead zone, which ultimately affects the energy storage and energy release effects of the system. Therefore, it is necessary to crystallize the working fluid of the absorbent in a set area with good heat exchange effect. Therefore, considering that the spiral tube heat exchanger 22 is immersed in the solution 04, the surface of the spiral tube heat exchanger 22 is rough and contains a large number of crystallization nuclei required for the crystallization process. When the concentration of solution 04 reaches the limit (crystal grains appear) in the solution energy storage process, cooling water can be qui...

Embodiment approach 2

[0036] Implementation Mode 2: Rapid Dissolving Crystal Energy Release Process

[0037] During the energy release process of the concentrated solution and absorbent crystals in the solution tank 02, there are two ways to dissolve the crystals quickly. One is to add an electric auxiliary heating belt 24 to the solution circulation loop 12 to heat the circulating liquid. To raise the temperature of the solution, the crystals are in solution. The second is that hot fluid can be passed into the spiral tube heat exchanger 22 to dissolve the crystals quickly. This process needs to open the valve 21, so that the refrigerant gas can be absorbed by the absorbent from the refrigerant tank 01 to the solution tank 02.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com