Switched reluctance motor torque control system based on improved PID control

A switched reluctance motor, torque control technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve the problems of reducing torque ripple and large torque ripple of switched reluctance motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

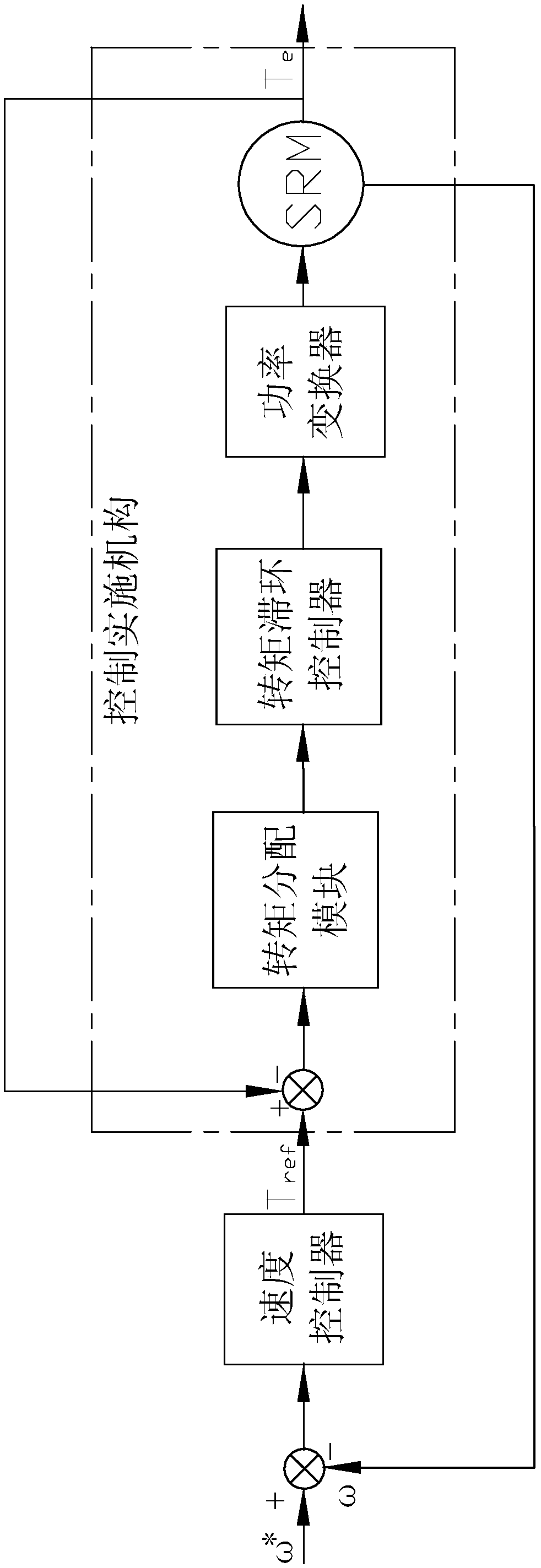

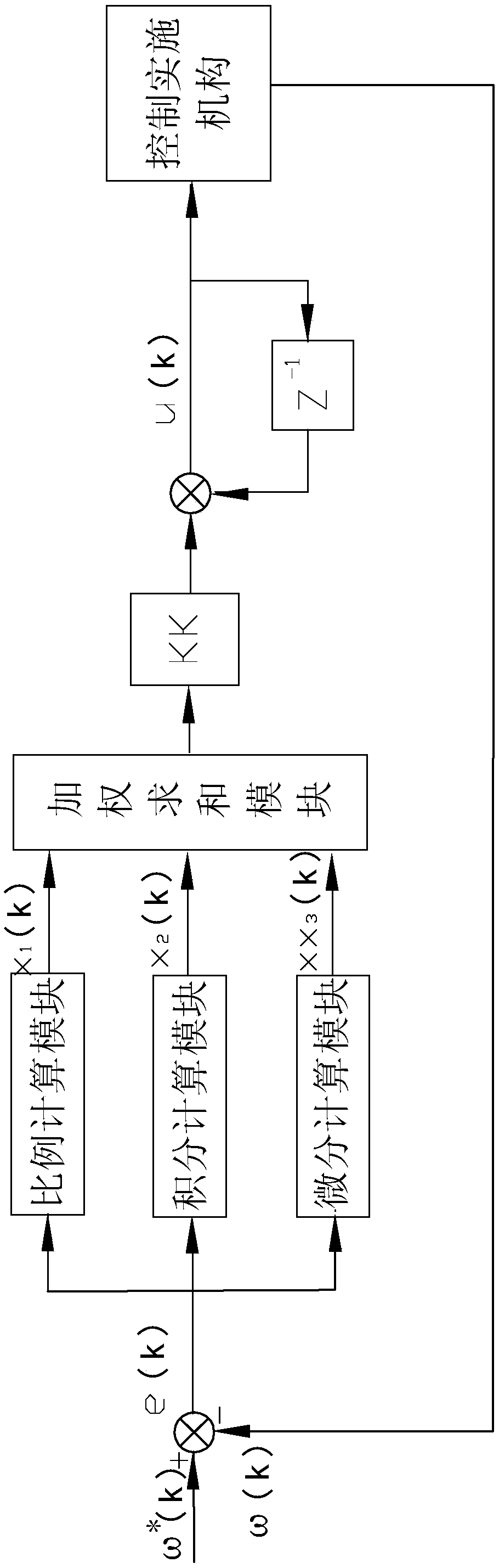

[0049] The microprocessor of embodiment 1 of the switched reluctance motor control system with improved PID control is equipped with a program memory and a data memory, and the program memory contains a speed and torque data acquisition module, an analog-to-digital conversion module, a speed controller, and a torque distribution module , Torque hysteresis controller, power converter and the rotor speed sensor and torque sensor installed on the switched reluctance motor, the output signal lines of each sensor are connected to the speed controller through the analog-to-digital conversion module, and the speed controller according to the given Speed ω * and the actual speed ω to get the reference torque T ref , the reference torque T ref with measured torque T e The difference is taken as the total torque deviation ΔT ref Connect to the torque distribution module, obtain the torque deviation of each phase of the switched reluctance motor through the torque distribution funct...

Embodiment 2

[0077] The overall block diagram of the system in this example is as follows figure 1 As shown, the speed controller in this example is a fuzzy-differential prior single-neuron PID speed controller.

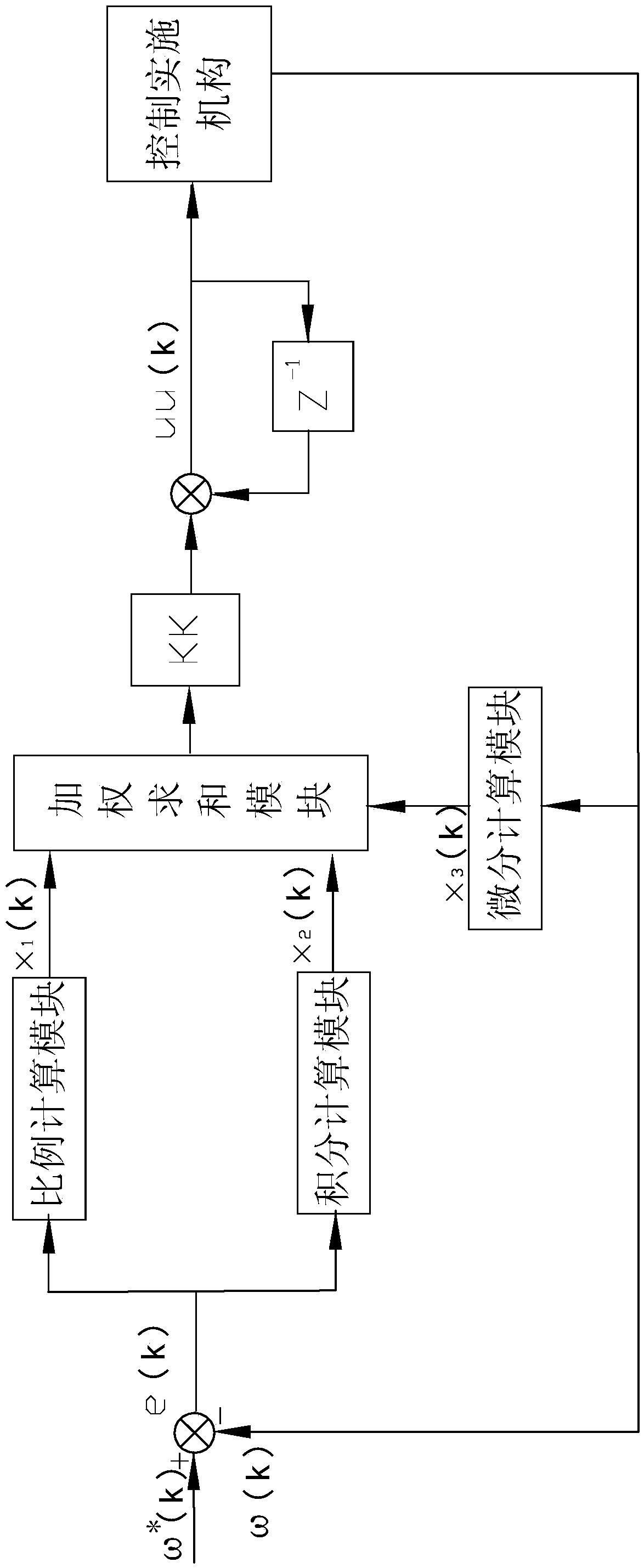

[0078] like Figure 4 As shown, this example introduces the classic fuzzy control module and the integral calculation module in parallel to form the integral fuzzy control module, and its output is used to dynamically adjust the output gain KK of the differential-first single-neuron PID speed controller. The classical fuzzy control module and the differential-first single-neuron The unit PID together constitutes the fuzzy-differential preceding single neuron PID speed controller.

[0079] The classic fuzzy control module in the integral fuzzy control module takes the speed deviation e(k) and the speed deviation increment Δe(k)=e(k)-e(k-1) as input, and its output is U PD . The integral calculator performs an integral calculation on the deviation e(k), and its output is x 2 (k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com