Crack initiation method adopting crack prefabricating and orientated hydraulic fracturing

A technology of prefabricated fractures and directional fracturing, which is applied in directional drilling, earthwork drilling, wellbore/well components, etc. It can solve problems such as extrusion of gas in gobs, pollution of underground air, and decline in recovery rate, achieving increased The effects of fracturing drilling spacing, drilling cost savings, and roadway load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

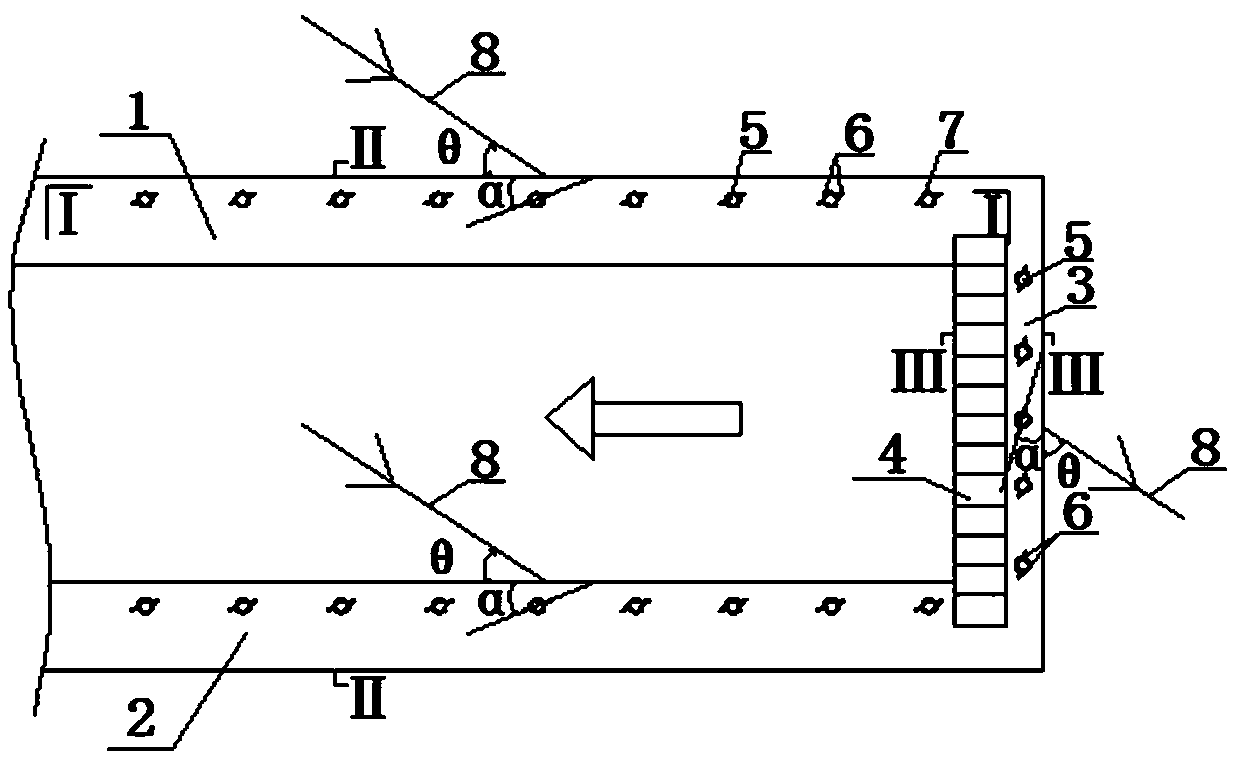

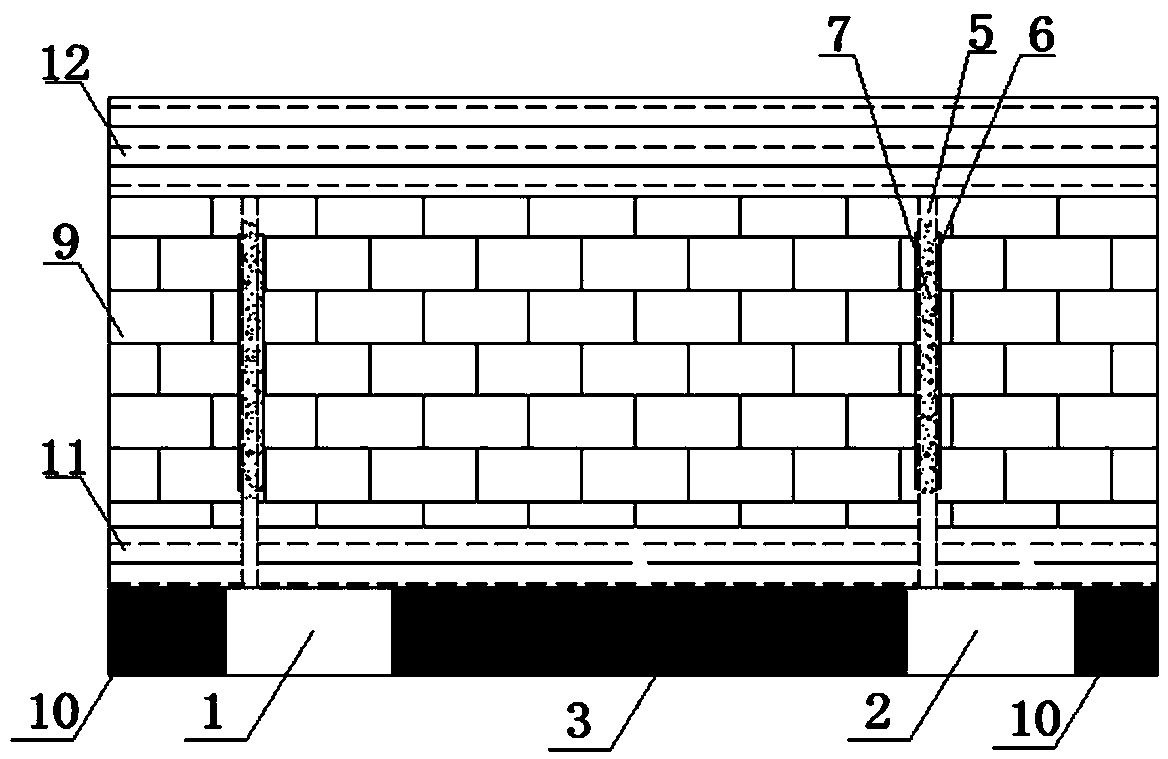

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing: A kind of prefabricated fracture directional fracturing initiation method of the present invention, at first measure the size and the orientation of the maximum horizontal stress in the hard rock formation 9 above the coal seam, then according to the work The direction of the long axis of face notch 3 or the direction of the long axis of transport trough 1 or return trough 2 is calculated. The direction of the long axis of the wind trough 2 or the angle between the cutting eye of the working face, the transport chute and the long axis direction of the return air chute, the measured angle between the maximum horizontal stress azimuth and the long axis is 30°. Cut hole 3 on the working face close to the coal pillar side or transport chute 1 close to the coal pillar side or return air chute close 2 to the working face side or at the same time cut eye on the worki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com