High-conductivity steel for anode rigid claw and preparation method of steel

A high-conductivity, anode steel claw technology, applied in the field of low-alloy steel, can solve the problems of poor metallurgical quality of anode steel claw materials, increase the production cost of electrolytic aluminum, increase the production cost of aluminum ingots, etc., and achieve good electrical conductivity and mechanical properties , low product cost, good technical and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

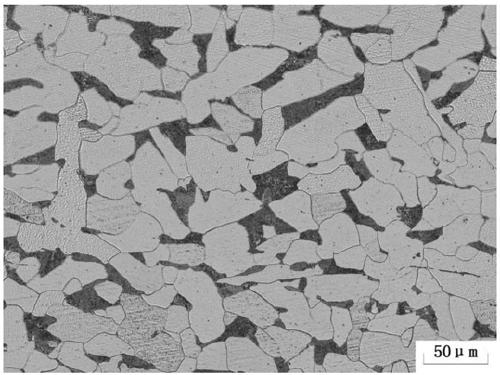

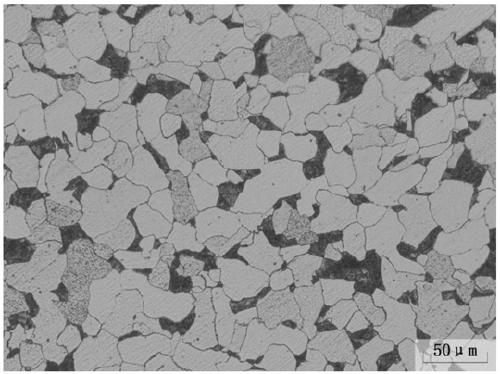

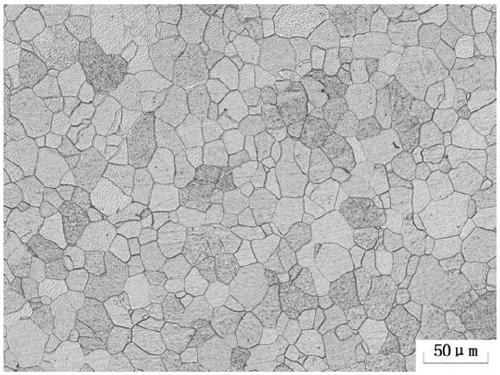

Image

Examples

preparation example Construction

[0057] The present invention also provides a preparation method of steel for high-conductivity anode steel claws, comprising the following steps:

[0058] S1. Batching according to the weight percentage of the composition and carrying out smelting and casting, raising the temperature of the billet to 1120-1280°C for soaking treatment for 2-4h;

[0059] S2. Rough rolling is carried out in the austenite recrystallization zone, the starting rolling temperature is 1100-1230°C, the finishing rolling temperature is 980-1030°C, and the cumulative deformation of rough rolling is 20%-40%;

[0060] S3. Finish rolling is carried out in the austenite non-recrystallization zone, the starting rolling temperature is 880-930°C, the finishing rolling temperature is 830-870°C, the cumulative deformation of finishing rolling is 30%-60%, and air-cooled to room temperature after rolling.

[0061] In the preparation method of the present invention, the soaking temperature of the slab is 1120-1280°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com