High-speed filling self-adaptive control system and method

An adaptive control, high-speed technology, applied in packaging, liquid bottling, transportation and packaging, etc., can solve problems such as increasing equipment development and maintenance costs, difficulty in ensuring high-precision filling control effects, and changes in filling characteristics. Achieve the effects of overcoming the influence of time-varying system characteristics, good market promotion prospects, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

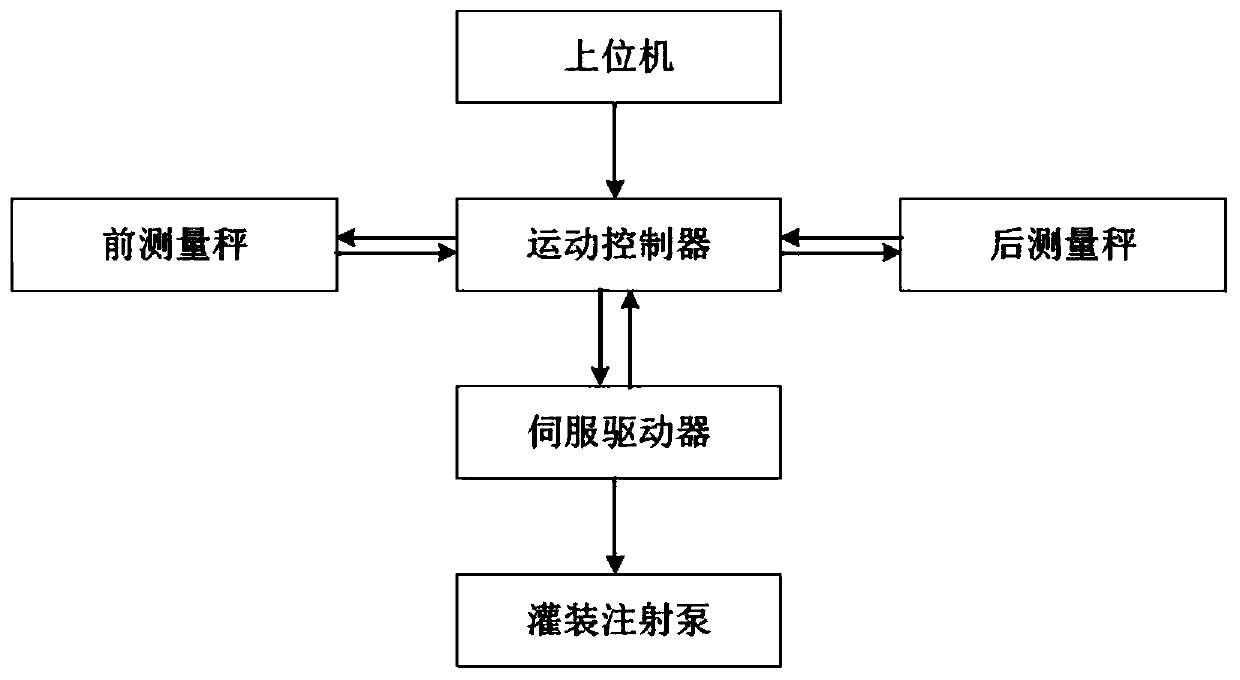

[0031] A high-speed canning adaptive control system is characterized in that it comprises a front measuring scale, a rear measuring scale, a motion controller, a servo drive, a filling syringe pump and a host computer. The high-speed filling system is connected with the motion controller through the upper computer to monitor the system in real time. The motion controller is connected with the front measuring scale and the rear measuring scale at the same time to obtain the weight data of the filling bottle before and after canning. The motion controller is connected with the servo driver and controls the injection stroke of the filling syringe pump, thereby realizing the control of the filling volume.

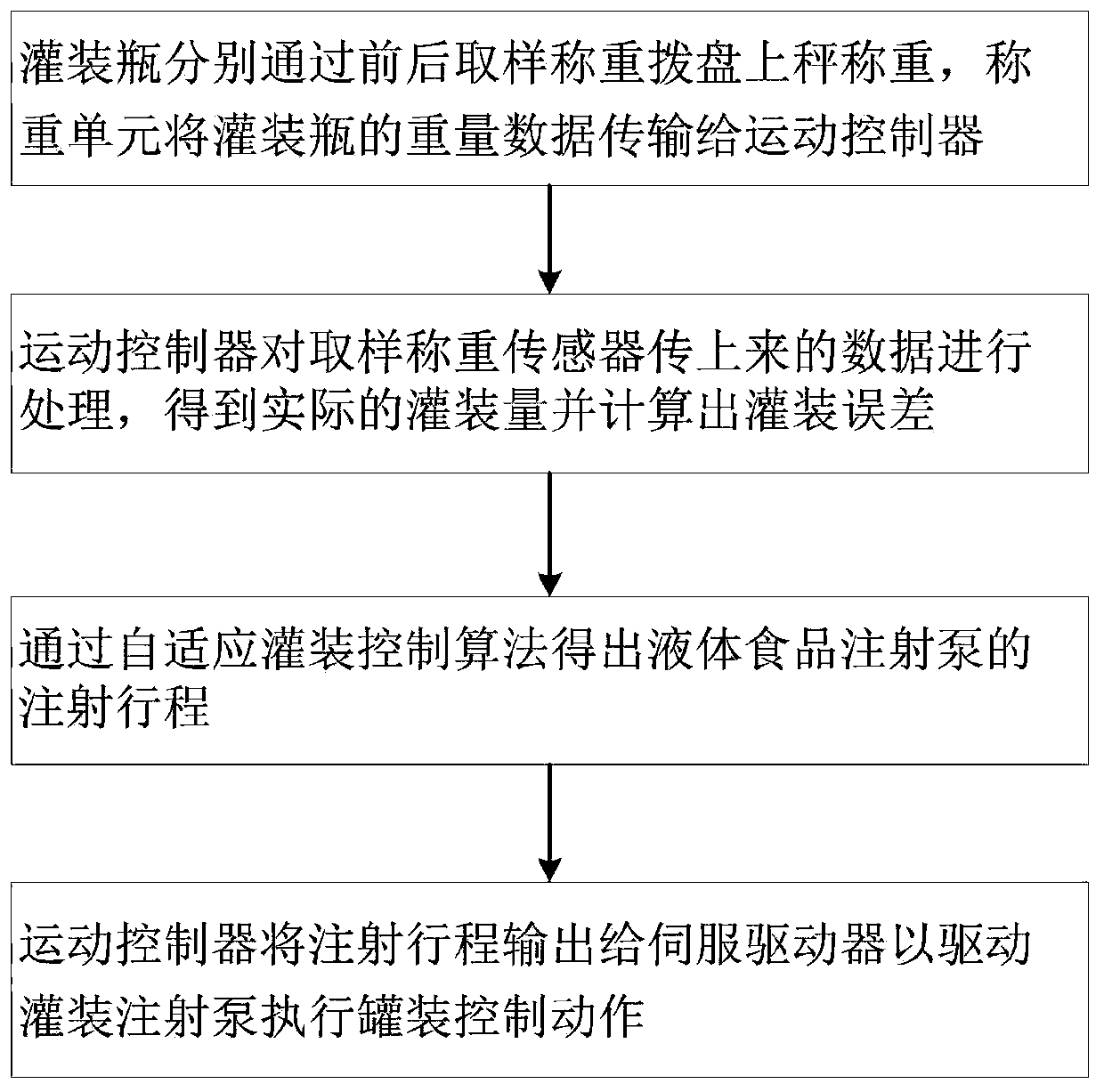

[0032] Applying described a kind of high-speed canning self-adaptive control method mainly comprises the following steps:

[0033] Step 1. Set the liquid food canning volume through the human-machine interface module of the host computer, start the system, and control the fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com