Water-based corrosion inhibition type rusted anti-rust coating and preparation method thereof

A rust-proof and corrosion-inhibiting technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as short service life, and achieve the effect of increasing anti-corrosion performance and improving anti-corrosion and anti-rust capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of "rust and anti-rust" functionalized cellulose-based airgel

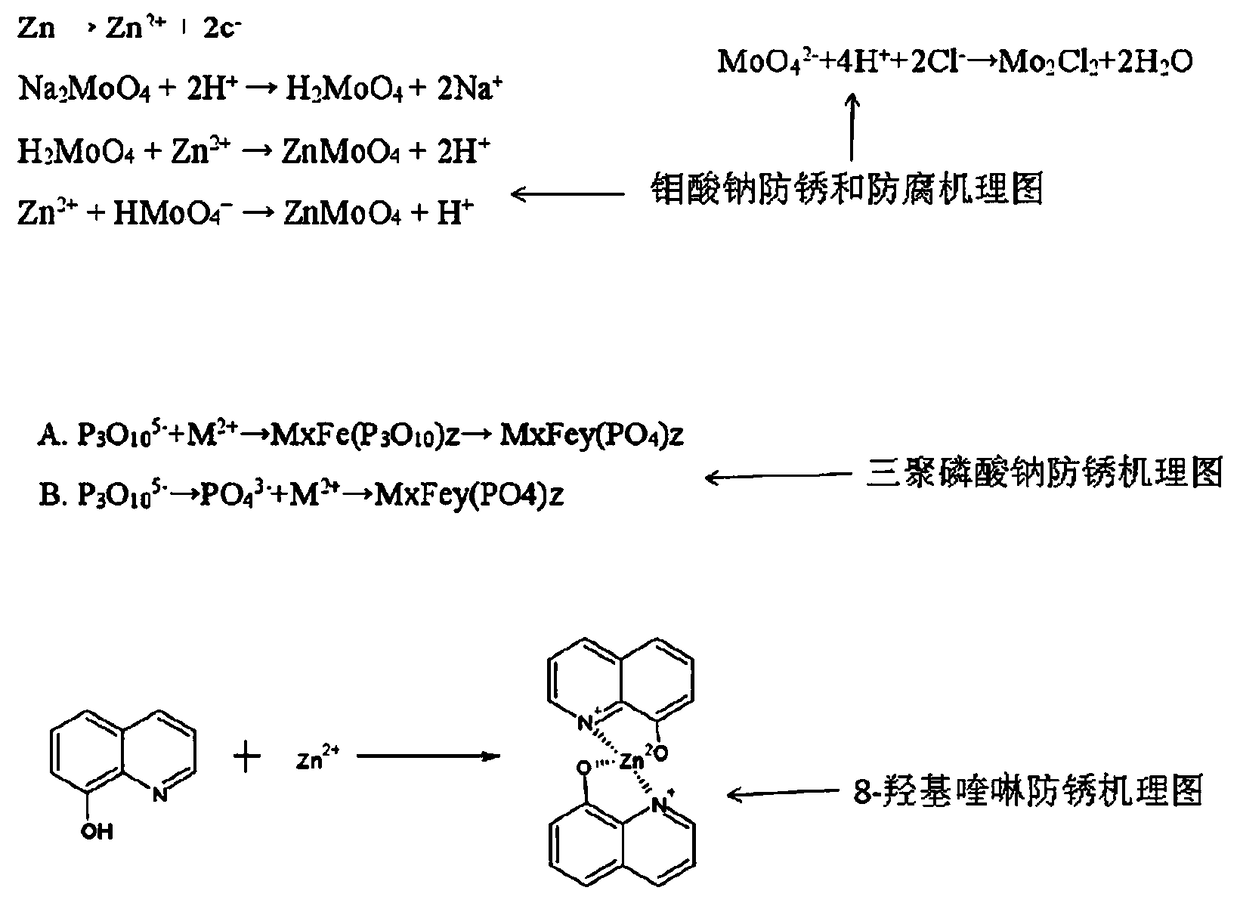

[0030] (a) Add 30 parts of methyl cellulose and 300 parts of deionized water into a beaker, stir for 20 minutes with electromagnetic stirring at a stirring speed of 100 r / min, add 100 parts of ice cubes made of deionized water into the beaker after stirring Use a cell pulverizer to pulverize the cellulose solution with ice cubes at a pulverization power of 1000W for 20 minutes, add 10 parts of sodium tripolyphosphate and 10 parts of sodium molybdate to it, and ultrasonically vibrate for 10 minutes with an ultrasonic power of 100W to obtain a liquid A;

[0031] (b) Freeze liquid A into a solid in a refrigerator at minus 3°C, freeze for 12 hours, put the frozen solid in a freeze dryer for 12 hours, freeze the liquid A at minus 55°C, and vacuum at 10Pa to obtain a powder B;

[0032] (c) Take 30 parts of powder B and add it to a beaker containing 200 parts of absolute ethanol, stir, add 10 par...

Embodiment 2

[0039] (1) Preparation of "rust and anti-rust" functionalized cellulose-based airgel

[0040] (a) Add 50 parts of hydroxyethylcellulose cellulose and 500 parts of deionized water into a beaker, stir for 30 minutes with electromagnetic stirring at a stirring speed of 150 r / min, and add 150 parts of deionized water to it after the stirring is completed. Ice cubes and use a cell crusher to crush the cellulose solution with ice cubes, the crushing power is 1300W, crush for 35min, add 10 parts of sodium tripolyphosphate and 10 parts of sodium molybdate to it, and ultrasonically vibrate for 20min, the ultrasonic power is 80W , to get liquid A;

[0041](b) Freeze liquid A at minus 4°C for 20 hours to form a solid, put the frozen solid into a freeze dryer for 20 hours, freeze and dry it at minus 60°C, and vacuum at 10 Pa to obtain powder B;

[0042] (c) Add 30 parts of powder B into a beaker containing 200 parts of absolute ethanol, add 10 parts of 8-hydroxyquinoline into the beaker,...

Embodiment 3

[0049] (1) Preparation of "rust and anti-rust" functionalized cellulose-based airgel

[0050] (a) Add 50 parts of carboxymethyl cellulose and 500 parts of deionized water into a beaker, stir it electromagnetically for 40 minutes at a stirring speed of 200 r / min, and add 100 parts of deionized water to the beaker after stirring. Block and use a cell crusher to crush the cellulose solution with ice cubes, the crushing power is 1500W, crush for 30min, add 10 parts of sodium tripolyphosphate and 10 parts of sodium molybdate to it, and ultrasonically vibrate for 30min, the ultrasonic power is 100W, get liquid A;

[0051] (b) Freeze liquid A at minus 5°C for 24 hours into a solid, and put the frozen solid into a freeze dryer for 12 hours to freeze dry at minus 55°C and a vacuum of 10 Pa to obtain powder B;

[0052] (c) Add 30 parts of powder B to a beaker containing 200 parts of absolute ethanol, add 10 parts of 8-hydroxyquinoline to the beaker, add 10 parts of trishydroxymethylami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com