Wood-plastic material prepared from papermaking waste and preparation method thereof

A technology of papermaking waste and wood-plastic materials, applied in the field of wood-plastic materials, can solve the problems of poor impact resistance and wear resistance, poor dispersion and surface adhesion, affecting the performance of wood-plastic materials, etc., and achieve water absorption Low, reduced polarity, wide range of raw material effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

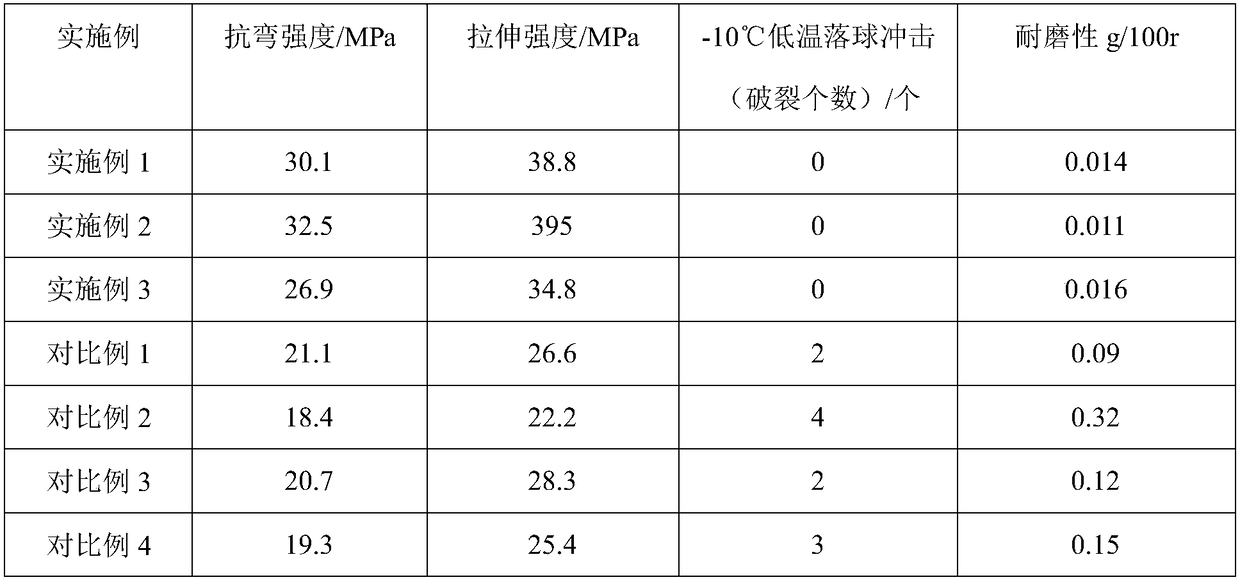

Examples

Embodiment 1

[0042] A wood-plastic material prepared from papermaking waste, including the following components in mass percentage: 35% of papermaking waste, 30% of wood powder with a particle size of 300 mesh, 16% of ceramic powder, 1% of sorbitol, silane Coupling agent vinyl triethoxysilane 3%, maleic anhydride grafted polyethylene 6%, aluminum chloride 2%, polyethylene glycol monomethyl ether 5%, blocked isocyanate 2%.

[0043] Preparation method: 1) Add silane coupling agent, maleic anhydride-grafted polyethylene, and aluminum chloride to a mixer in sequence and mix them at a mixing temperature of 30°C to obtain a mixture;

[0044] 2) Raise the temperature to 60°C, add sorbitol, wood powder and papermaking waste to the mixture, stir evenly, the stirring speed is 50r / min, continue to heat up to 120°C after 20min, add blocked isocyanate, polyethylene glycol monomethyl Ether and ceramic powder were mixed for 50 minutes, cooled to 40°C, and the obtained mixture was granulated and extruded ...

Embodiment 2

[0046] A wood-plastic material prepared from papermaking waste, including the following components in mass percentage: 30% of papermaking waste, 35% of wood powder with a particle size of 100 mesh, 20% of ceramic powder, 3% of sorbitol, silane Coupling agent γ-aminopropyltriethoxysilane 2%, maleic anhydride grafted polyethylene 4%, aluminum chloride 1%, polyethylene glycol monomethyl ether 4%, blocked isocyanate 1%.

[0047] Preparation method: 1) Add silane coupling agent, maleic anhydride-grafted polyethylene, and aluminum chloride to a mixer in sequence and mix them at a mixing temperature of 35°C, and mix to obtain a mixture;

[0048] 2) Raise the temperature to 70°C, add sorbitol, wood powder and papermaking waste to the mixture, stir evenly, the stirring speed is 100r / min, continue to heat up to 110°C after 15min, add blocked isocyanate, polyethylene glycol monomethyl Ether and ceramic powder were mixed for 40 minutes, cooled to 40°C, and the obtained mixture was granula...

Embodiment 3

[0050] A wood-plastic material prepared from papermaking waste, including the following components in mass percentage: 30% of papermaking waste, 40% of wood powder with a particle size of 200 mesh, 15% of ceramic powder, 5% of sorbitol, silane Coupling agent methacryloxypropyl trimethoxysilane 1%, maleic anhydride grafted polyethylene 3%, aluminum chloride 2%, polyethylene glycol monomethyl ether 3%, blocked isocyanate 1%.

[0051] Preparation method: 1) Add silane coupling agent, maleic anhydride-grafted polyethylene, and aluminum chloride into a mixer in sequence and mix them at a mixing temperature of 40°C to obtain a mixture;

[0052] 2) Raise the temperature to 68°C, add sorbitol, wood powder and papermaking waste to the mixture, stir evenly, the stirring speed is 80r / min, and then continue to heat up to 100°C after 10min, add blocked isocyanate, polyethylene glycol monomethyl Ether and ceramic powder were mixed for 30 minutes, cooled to 40°C, and the obtained mixture was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com