Concentrated solution resourceful treatment and refuse waterproof covering in-situ application process of refuse landfill

A landfill and concentrated solution technology, which is applied in the direction of landfill technology and solid waste removal, can solve the problems of large storage capacity loss, high covering cost, and intensified recharge of concentrated solution, achieving high cost performance and good quality. The effect of environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0025] Example 1

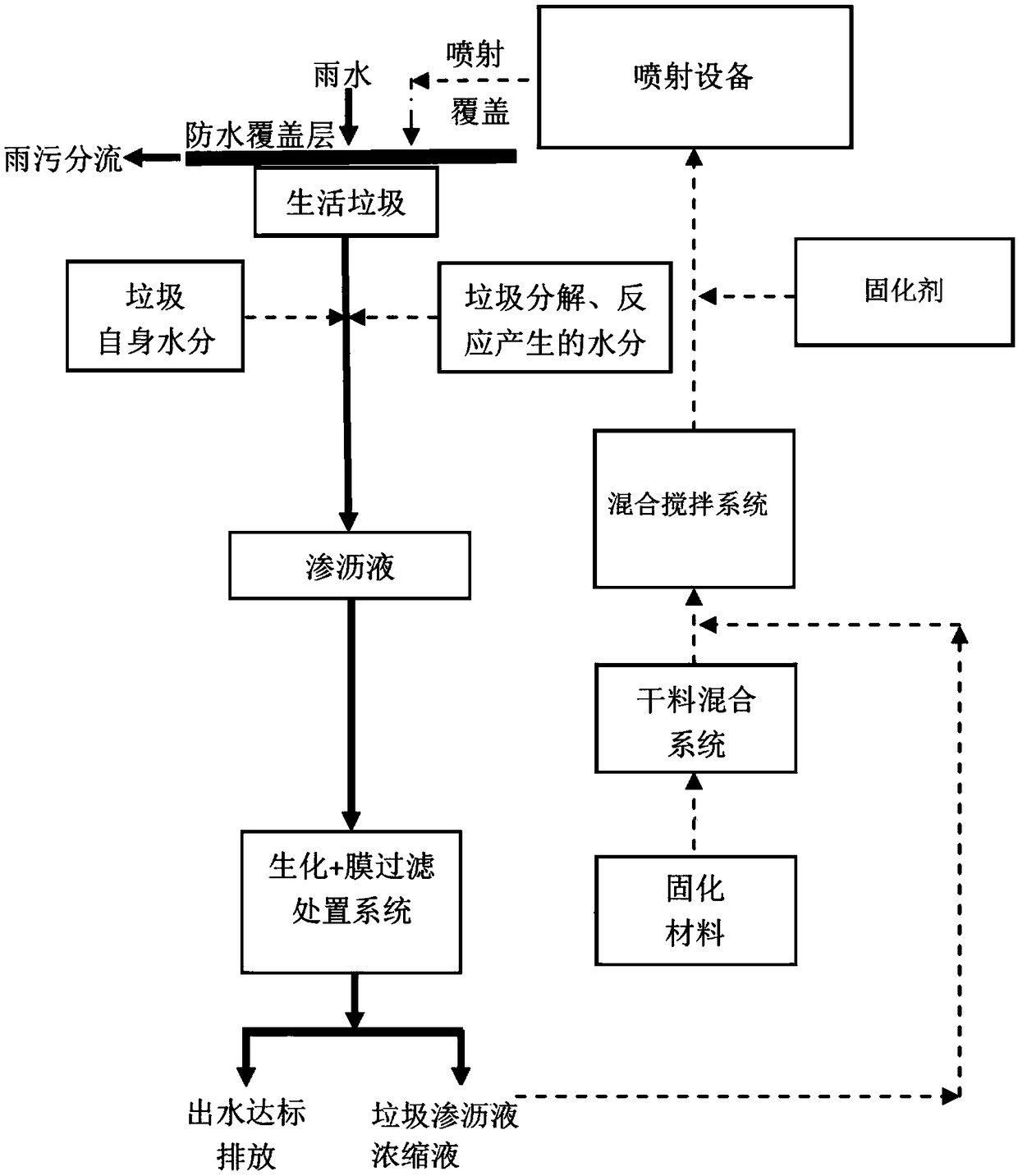

[0026] Such as figure 2 As shown, in this embodiment, the waste landfill concentrated liquid resource treatment and the in-situ application process of waste waterproof covering include the following steps:

[0027] ①Put the cured base material into the dry material mixing system for mixing, and mix for 4 minutes at normal temperature and pressure to form a cured base material mixture;

[0028] ②Put the leachate concentrate produced by biochemical and membrane filtration processes together with the solidified base material mixture into the mixing system and stir evenly, and stir for 5 minutes at normal temperature and pressure to form a uniform mixture;

[0029] ③ Add curing agent to the homogeneous mixture to form a high-viscosity paste composite material, and use spraying equipment to spray the homogeneous mixture evenly on the surface of the la...

Embodiment 2

[0038] In this embodiment, the waste landfill concentrated liquid resource treatment and waste waterproof covering in-situ application process include the following steps:

[0039] ①Put the solidified base material into a dry material mixer for mixing, and mix for 30 minutes at normal temperature and pressure to form a solidified base material mixture; the dry material mixer is 20 rpm, 50m 3 .

[0040] ②Put the leachate into the JS500 concrete mixer together with the concentrated liquid produced by the biochemical and membrane filtration process together with the solidified base material mixture, and stir evenly at room temperature and pressure for 30 minutes to form a uniform mixture;

[0041] ③ Add curing agent to the uniform mixture, use the ECA-3000 hydraulic injection equipment produced by LSC to directly cover the landfill in situ, spray the uniform mixture evenly on the surface of the landfill operation area, and evenly mix the mixture Attached to the surface of the ga...

Embodiment 3

[0046] The solidified base material described in this example is composed of posi-shell and cement, the patented product of LSC Company of the United States, and the weight ratio of posi-shell and cement is 1:2.5.

[0047] The curing agent is composed of quicklime, a mixture of sodium bentonite and diatomaceous earth, a mixture of calcium dihydrogen phosphate and sodium dihydrogen phosphate in a ratio of 10:10:1 by weight, and the sodium bentonite The mixture with diatomite is composed of sodium bentonite and diatomite according to any weight ratio; the mixture of calcium dihydrogen phosphate and sodium dihydrogen phosphate is composed of calcium dihydrogen phosphate and sodium dihydrogen phosphate according to Composed of any ratio of parts by weight.

[0048] The parts by weight of the curing agent and the homogeneous mixture are 1:150.

[0049] The ratio of parts by weight of the solidified base material to the concentrated solution is 1:3.0.

[0050] The cured base mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com