Compact vibration harvesting device for fruit harvesting

A vibrating device, a compact technology, used in applications, pickers, harvesters, etc., can solve the problems of difficult to control damage rate, high air tightness requirements, and large damage to the resultant branches, and achieves reduced damage, compact structure, and guaranteed The effect of the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

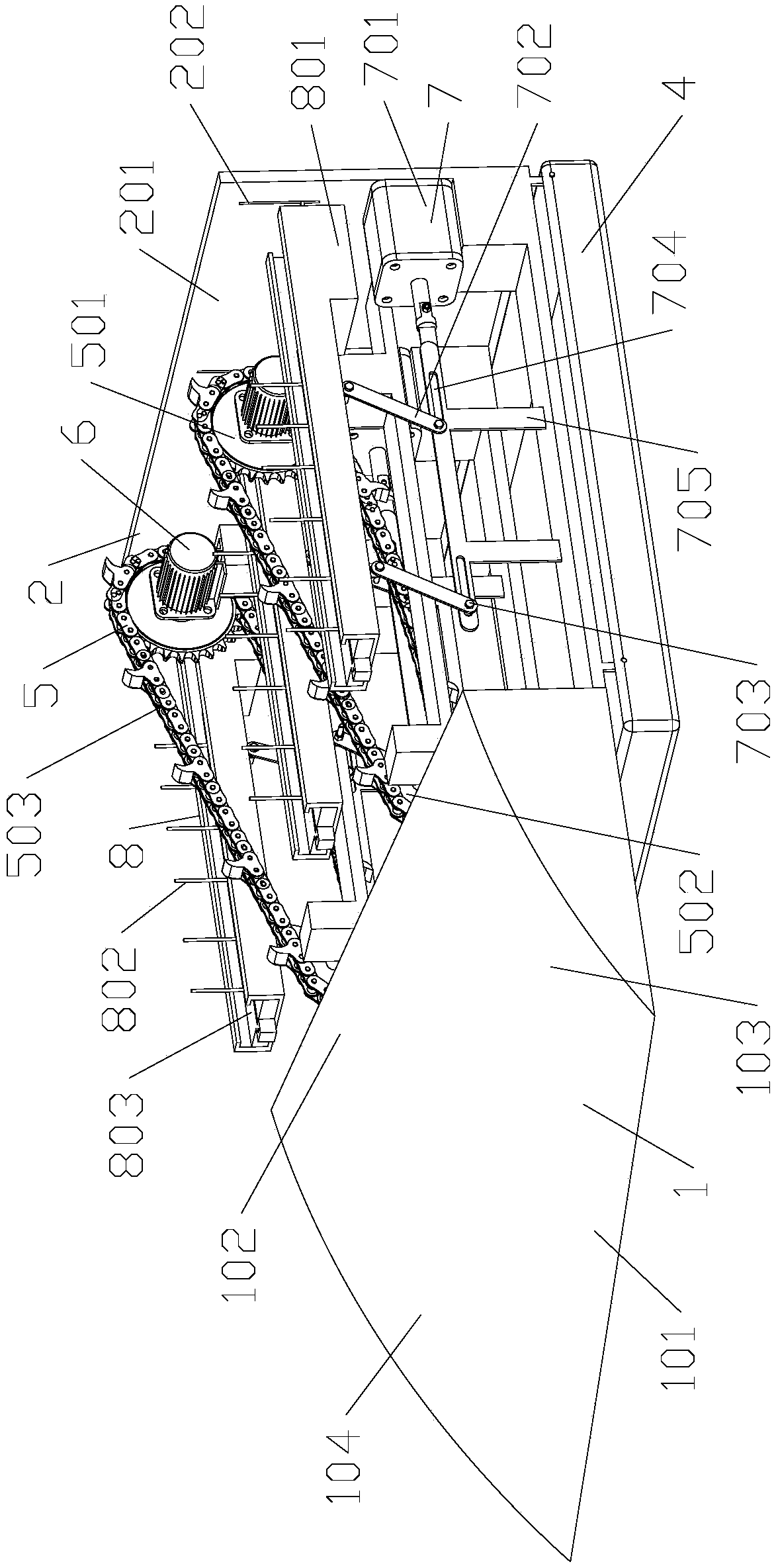

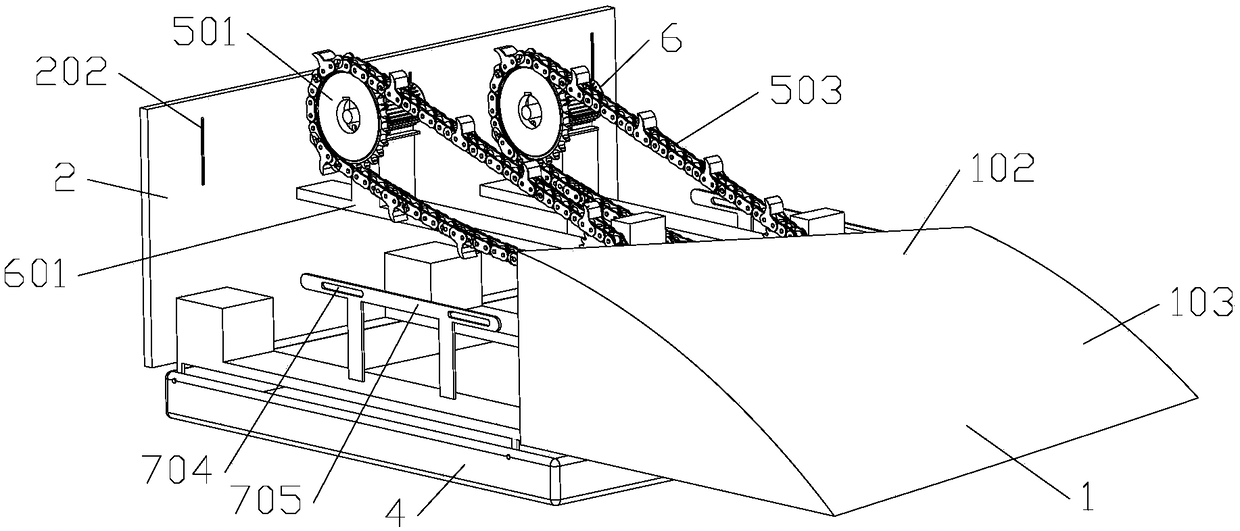

[0025] see figure 1 , 2 As shown, the compact vibration harvesting device for fruit harvesting includes: guide plate 1, frame 2 (including vertical plate 201, etc.), collection box 4 fixed in front of the lower part of the vertical plate, branch holding device 5, up and down drive Mechanism 7, gear shaping vibration device 8.

[0026] see figure 1 , The branch holding device 5 includes a chain 503, a large sprocket 501, a small sprocket 502, a branch conveying drive motor 6, a support arm 601 fixed on a vertical plate, and the like.

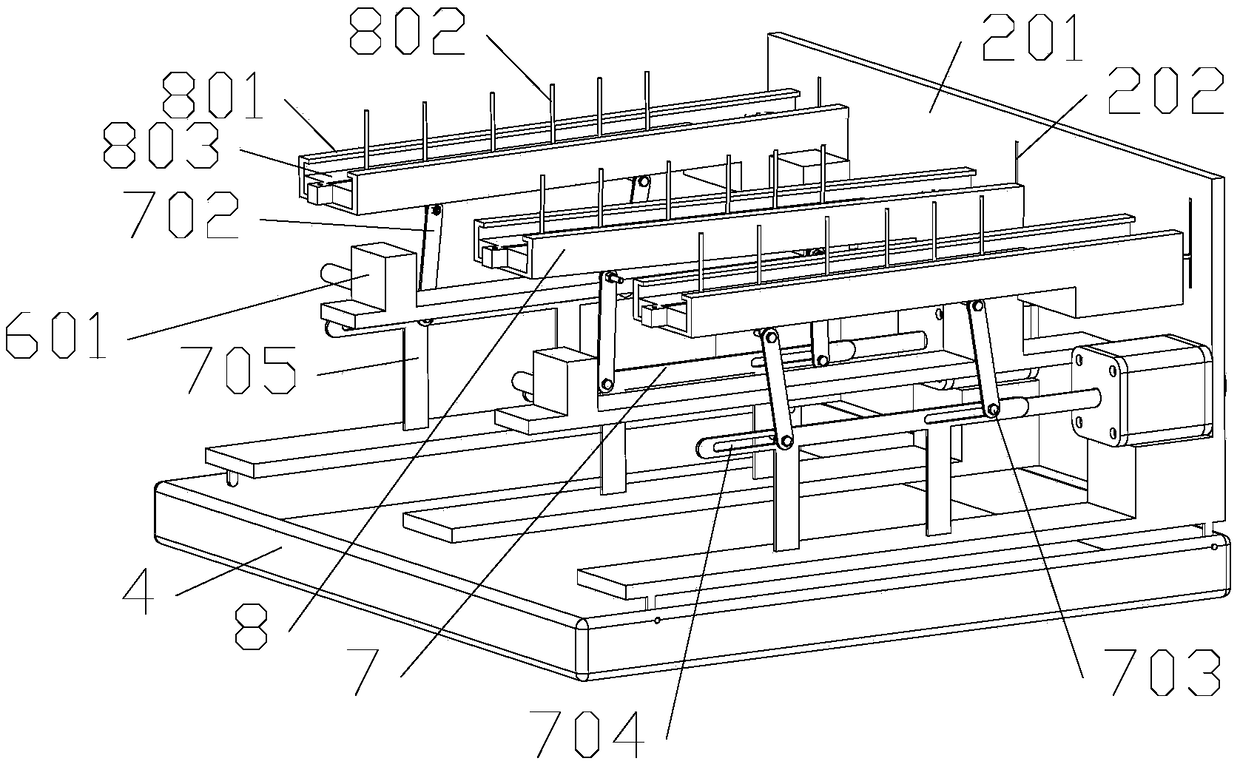

[0027] see Figure 3-5 The gear shaping vibration device 8 includes a gear shaping guide rail 801, a gear shaping 802, a tooth shaping fixed plate 803, and a vibrating mechanism 9 (including a connecting rod 901, a crank 902, and a horizontal drive motor 10 fixed on the tooth shaping fixed plate 803).

[0028] The up and down driving mechanism 7 comprises a cylinder 701, two parallel and equal length swing rods 702, a slide pin 703 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com