3D printing and forming integrated program-controlled valve group

A technology of 3D printing and program-controlled valve group, which is applied in the direction of multi-way valves, valve devices, valve details, etc., can solve the problems of poor surface performance of the flow channel wall, and achieve the effect of compact structure of the valve area, cost saving and easy modularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

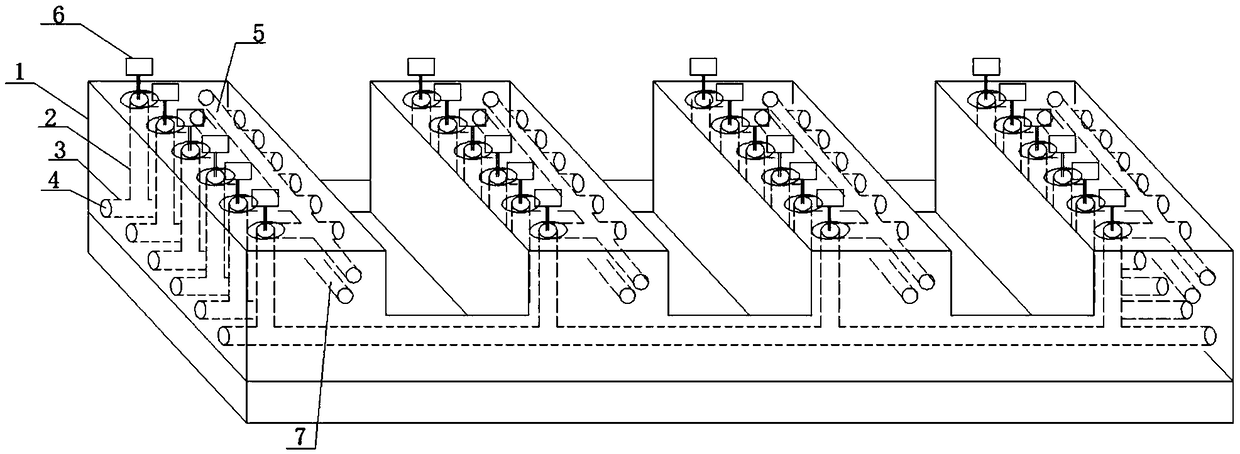

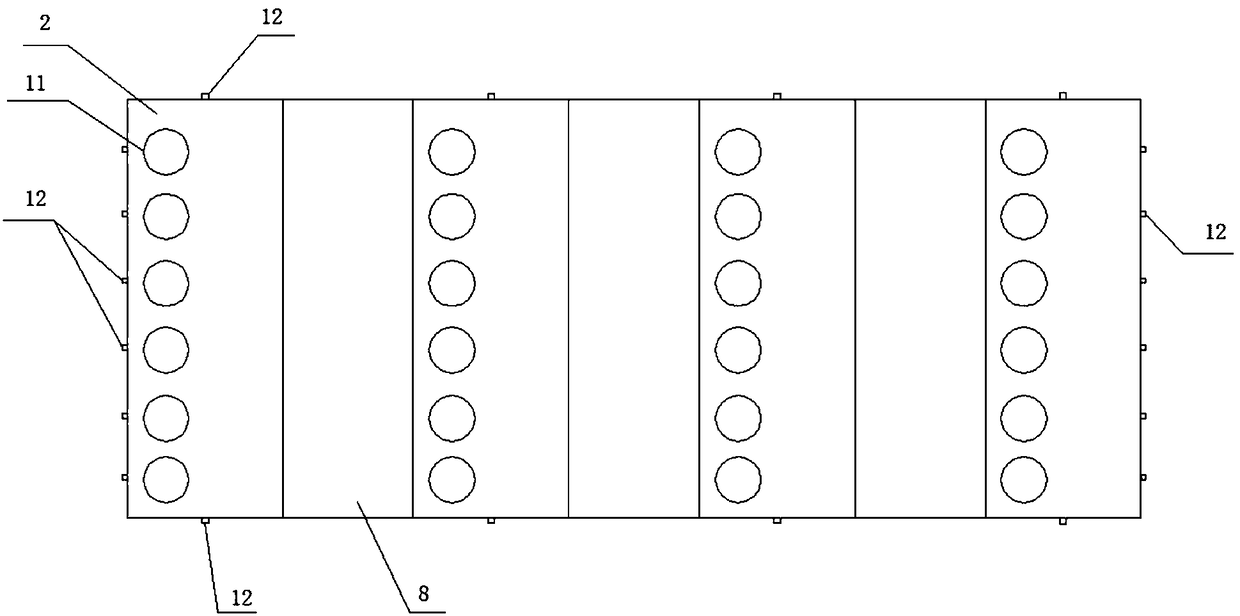

[0081] This embodiment provides an integrated program-controlled valve group for the problem that the valve area of the existing adsorption treatment system is too large and is not convenient for integrated skid-mounted design, specifically including: the valve group body; the valve group body is set There are several unit blocks 1, and the bottom is provided with several converging flow channels 3 that pass through the unit blocks 1 left and right; the unit block 1 is provided with an inlet flow channel 7 and an outlet flow channel 55 that pass through the unit block 1 front and rear, and A plurality of branch flow channels 2 corresponding to the converging flow channel 3 one-to-one; one end of each of the branch flow channels 2 is communicated with the outlet flow channel 55, and the other end is in communication with the corresponding converging flow channel 3, and each of the branch flow channels Channels 2 are provided with controllable valves 6; the surface of the unit ...

Embodiment 2

[0106] An integrated program-controlled valve group formed by 3D printing, comprising the following steps:

[0107] 1) Raw material preparation: According to the needs of the integrated program-controlled valve group, prepare skeleton materials, permeable materials and support materials;

[0108] 2) Printing and molding: use a multi-nozzle 3D printer to print layer by layer according to the shape and size of the integrated program-controlled valve group, and form a preliminary molded part; each layer is made of skeleton material, permeable material and support material. one or more of the constituents of

[0109] 3) Part sintering: the preliminary formed part obtained in step 2 is preheated, supported material consolidated, carburized, and quenched and tempered to obtain a sintered formed part;

[0110] 4) Part cleaning: After blowing off the pyrolysis residues and ultrasonic water washing of the sintered shaped part obtained in step 3, the shaped part is obtained.

[0111] ...

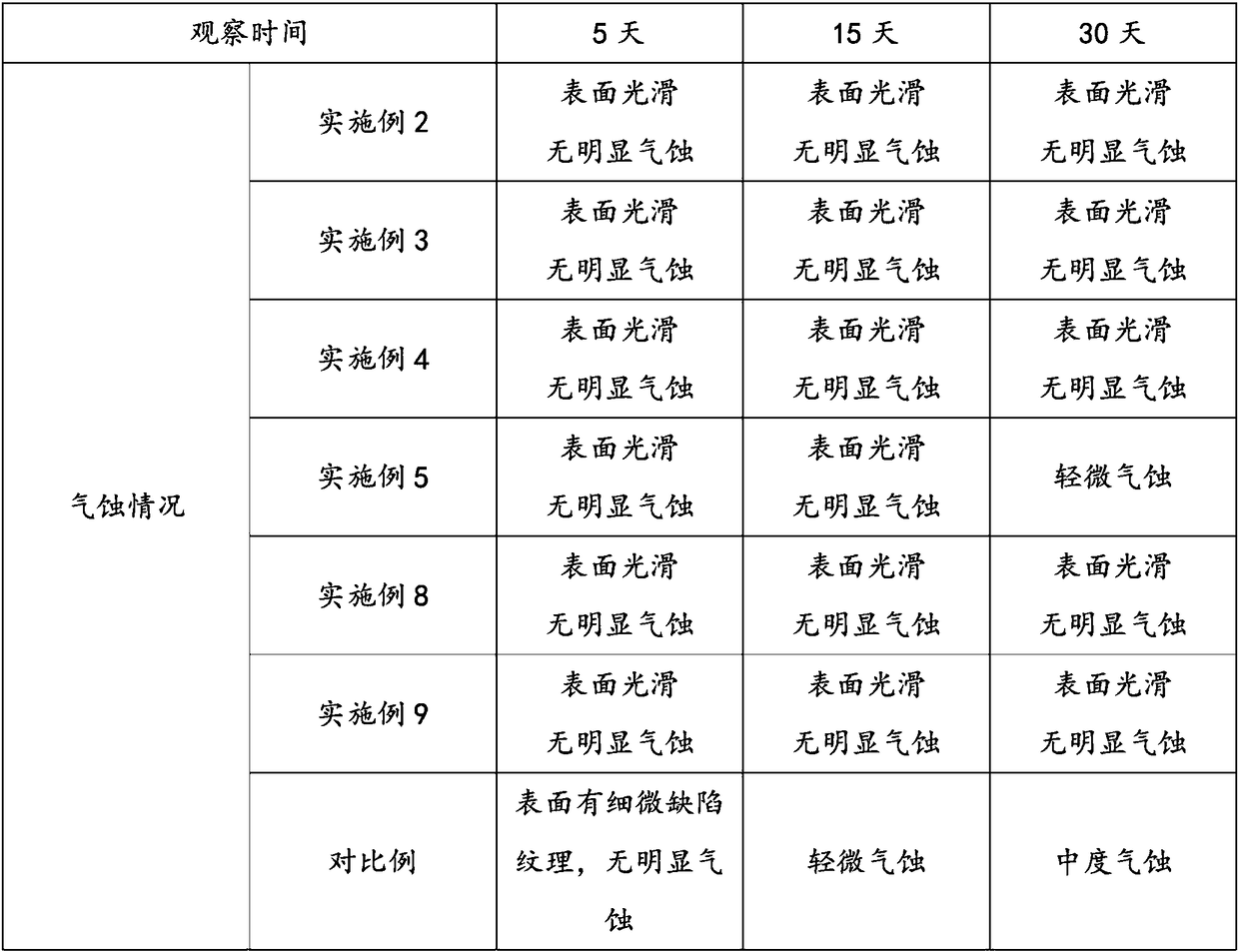

Embodiment 3

[0125] An integrated program-controlled valve group formed by 3D printing, comprising the following steps:

[0126] 1) Raw material preparation: According to the needs of the integrated program-controlled valve group, prepare skeleton materials, permeable materials and support materials;

[0127] 2) Printing and molding: use a multi-nozzle 3D printer to print layer by layer according to the shape and size of the integrated program-controlled valve group, and form a preliminary molded part; each layer is made of skeleton material, permeable material and support material. one or more of the constituents of

[0128] 3) Part sintering: the preliminary formed part obtained in step 2 is preheated, supported material consolidated, carburized, and quenched and tempered to obtain a sintered formed part;

[0129] 4) Part cleaning: After blowing off the pyrolysis residues and ultrasonic water washing of the sintered shaped part obtained in step 3, the shaped part is obtained.

[0130] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com