A method for preparing negative electrode material by dry distillation of coal tar at medium and low temperature

A negative electrode material, coal tar technology, applied in chemical instruments and methods, battery electrodes, carbon compounds, etc., can solve the problems of waste of chemical resources and low value, and achieve the effect of efficient use of energy, easy operation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Put the medium and low temperature carbonized coal tar pitch in the reaction kettle, raise the temperature under normal pressure and cut off the fraction before 300°C, and the gas phase can reach up to 320°C. Heating was stopped, the temperature was lowered, and light components and heavy components were obtained by separation.

[0058] Light components can be sold as high value-added products such as raw materials for producing clean fuel oil and octane adjustment for gas and diesel.

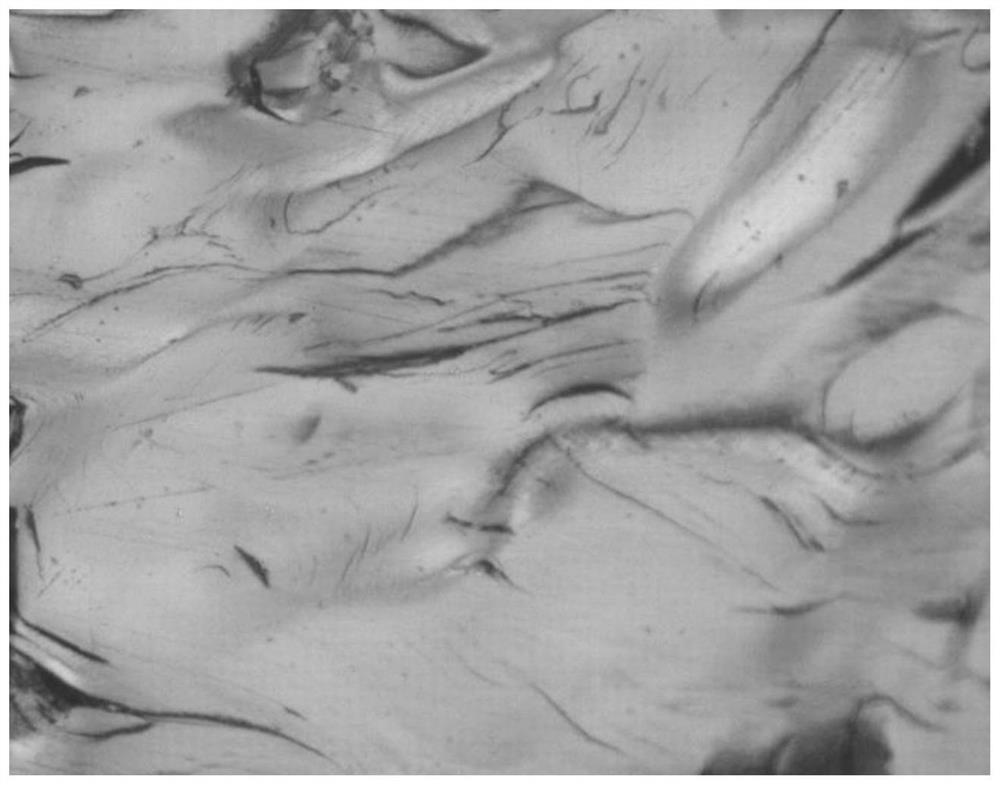

[0059] The quinoline insoluble content of the heavy component is 0.55% according to the analysis of the national standard. It is directly used as the raw material for the preparation of the negative electrode material precursor and put into the small coking tower for carbonization reaction. The heating rate is 15°C / min to 500°C, and the carbonization occurs at the same time The gas is discharged through the vent valve, and the pressure is kept not exceeding 2MPa until the carbonization i...

Embodiment 2

[0061] Put the medium and low temperature dry distillation coal tar pitch in the reaction kettle, carry out vacuum distillation under the vacuum degree of 0.07MPa, raise the temperature and cut off the distillate before 250°C, and the gas phase can reach up to 260°C. Heating was stopped, the temperature was lowered, and light components and heavy components were obtained by separation.

[0062] Light components can be sold as high value-added products such as raw materials for producing clean fuel oil and octane adjustment for gas and diesel.

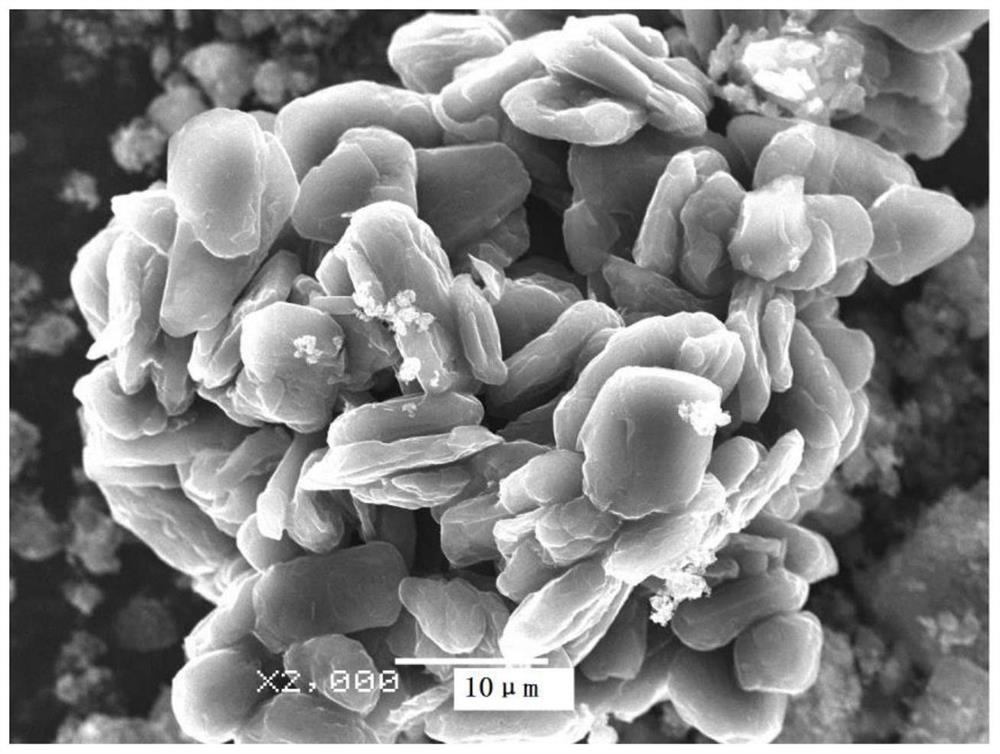

[0063] The heavy components were loaded into the reactor, and polymerized under normal pressure, the temperature was raised to 430°C at 4°C / min, and the temperature was kept constant for 14h to obtain the raw material of the negative electrode material precursor. According to the national standard analysis, the content of quinoline insolubles is 4.64%. It is directly used as the raw material prepared by the negative electrode material p...

Embodiment 3

[0065] Put the medium and low temperature dry distillation coal tar pitch in the reaction kettle, carry out vacuum distillation under the vacuum degree of 0.07MPa, raise the temperature and cut off the distillate before 250°C, and the gas phase can reach up to 260°C. Heating was stopped, the temperature was lowered, and light components and heavy components were obtained by separation.

[0066] Light components can be sold as high value-added products such as raw materials for producing clean fuel oil and octane adjustment for gas and diesel.

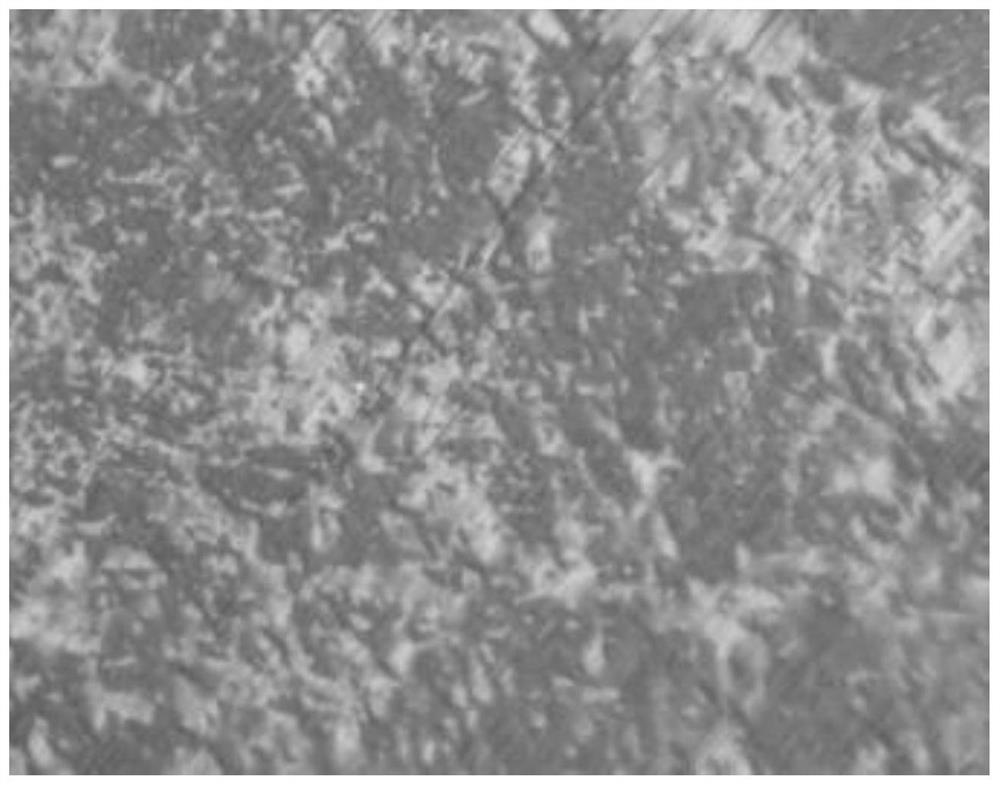

[0067] The heavy components were loaded into the reactor, and polymerized under normal pressure, the temperature was raised to 435°C at 6°C / min, and the temperature was kept constant for 14h to obtain the raw material of the negative electrode material precursor. According to the national standard analysis, the content of quinoline insolubles is 10.34%. It is directly used as the raw material prepared by the negative electrode material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com