Treatment method for dust hazard in textile factory

A processing method and technology for textile mills, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as mechanical wear and running obstacles, human health hazards, fires, etc., to reduce dust hazards and improve practicability , The effect of reducing the amount of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

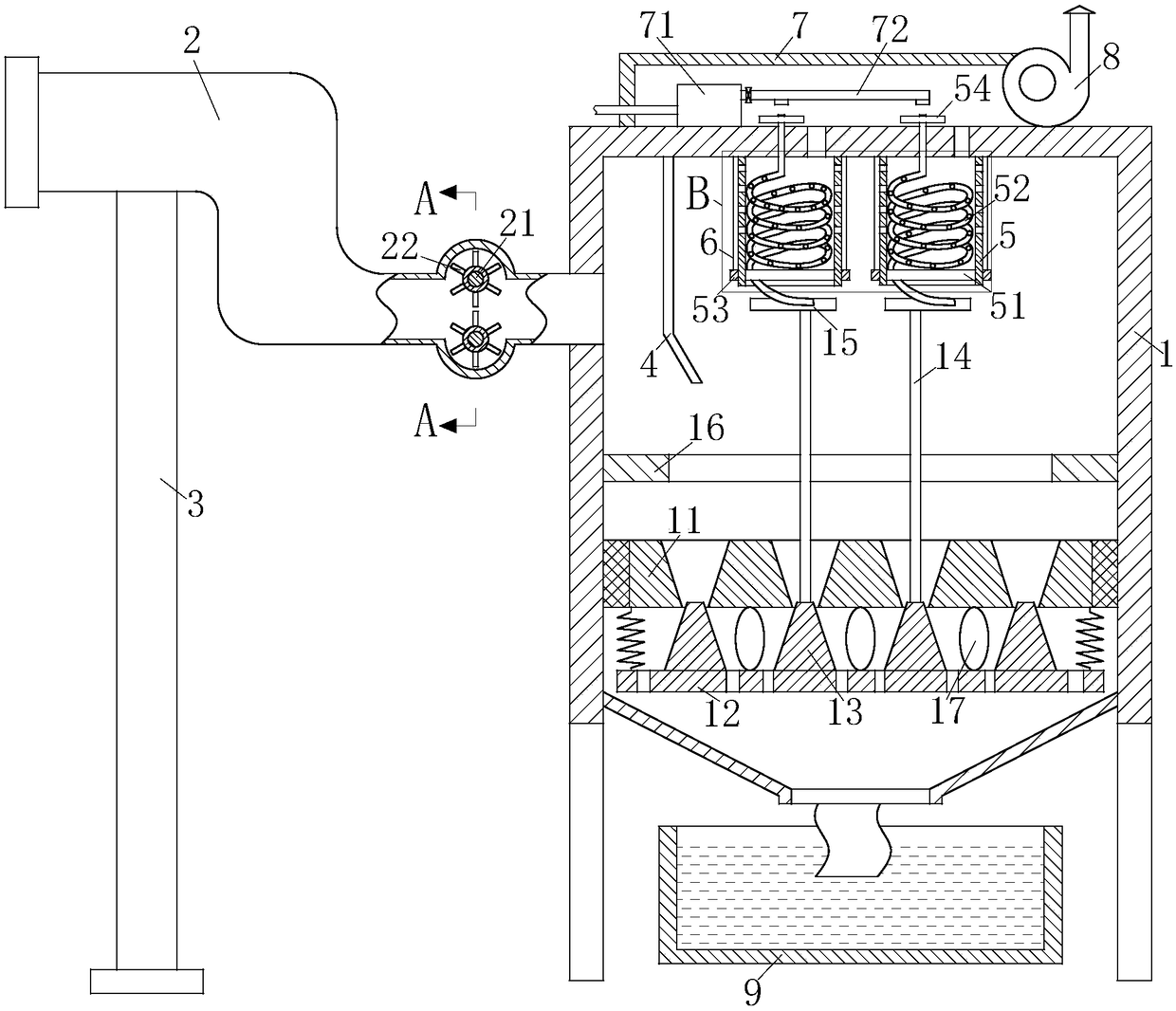

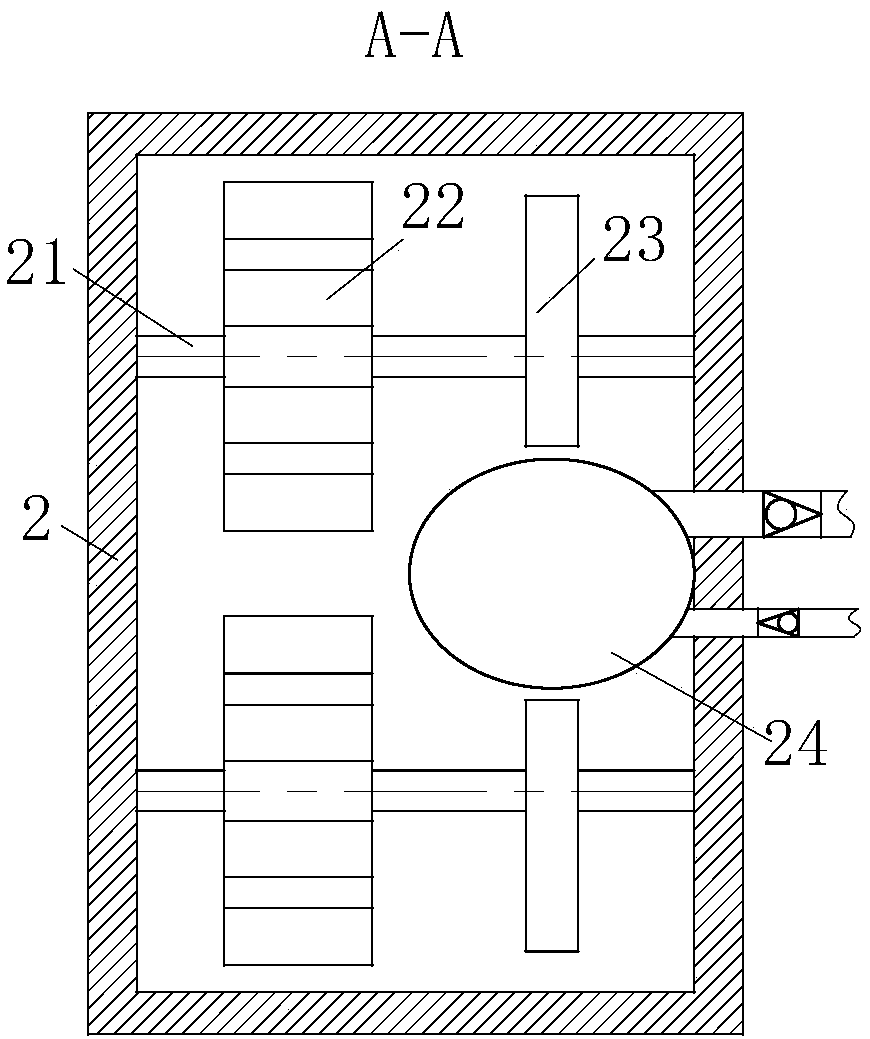

[0025] use Figure 1-Figure 4 The treatment method for dust hazards in textile mills according to an embodiment of the present invention is described as follows.

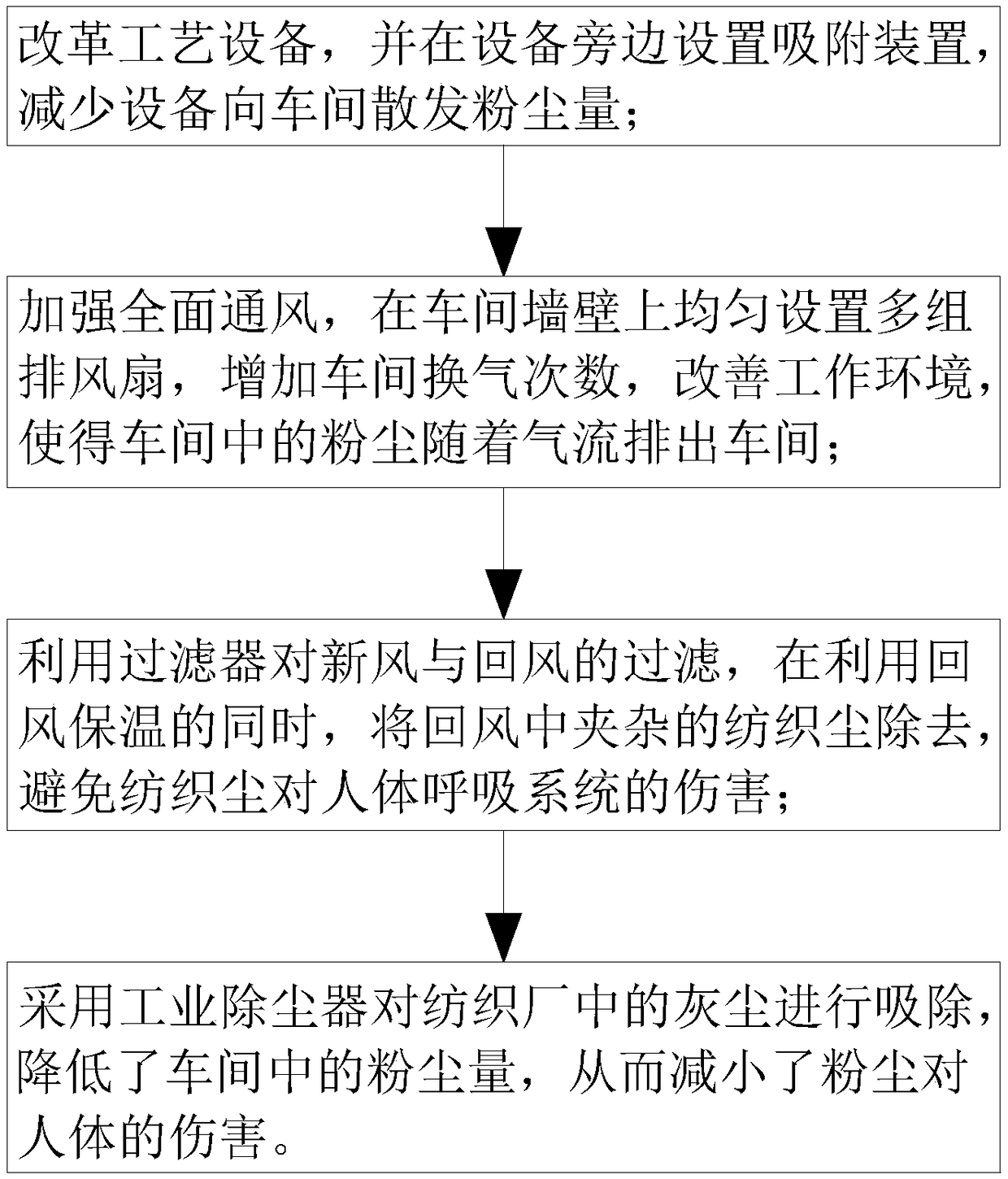

[0026] Such as figure 1 and figure 2 Shown, a kind of processing method for textile mill dust hazard of the present invention, the method comprises the steps:

[0027] Step 1: Reform the process equipment, and install an adsorption device next to the equipment to reduce the amount of dust emitted by the equipment to the workshop, and prevent the dust in the equipment from spreading harmful substances in the equipment to the workshop;

[0028] Step 2: After improving the equipment in step 1, strengthen the overall ventilation, install multiple groups of exhaust fans evenly on the workshop wall, increase the number of ventilation in the workshop, and improve the working environment, so that the dust in the workshop will be discharged out of the workshop with the air flow, reducing the dust in the workshop. The har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com