Circulating environment-friendly treatment process and circulating environment-friendly treatment system for waste viscose liquid

A technology for environmental protection and waste liquid treatment, which can be used in textile industry wastewater treatment, filtration treatment, multi-stage water treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

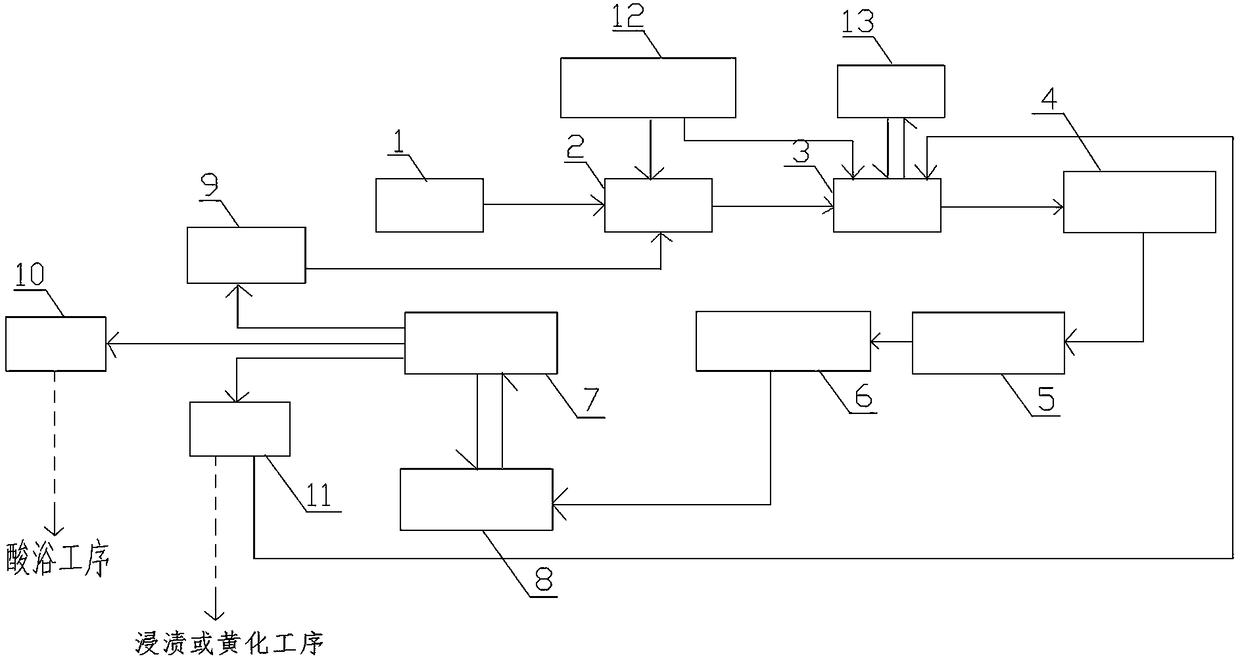

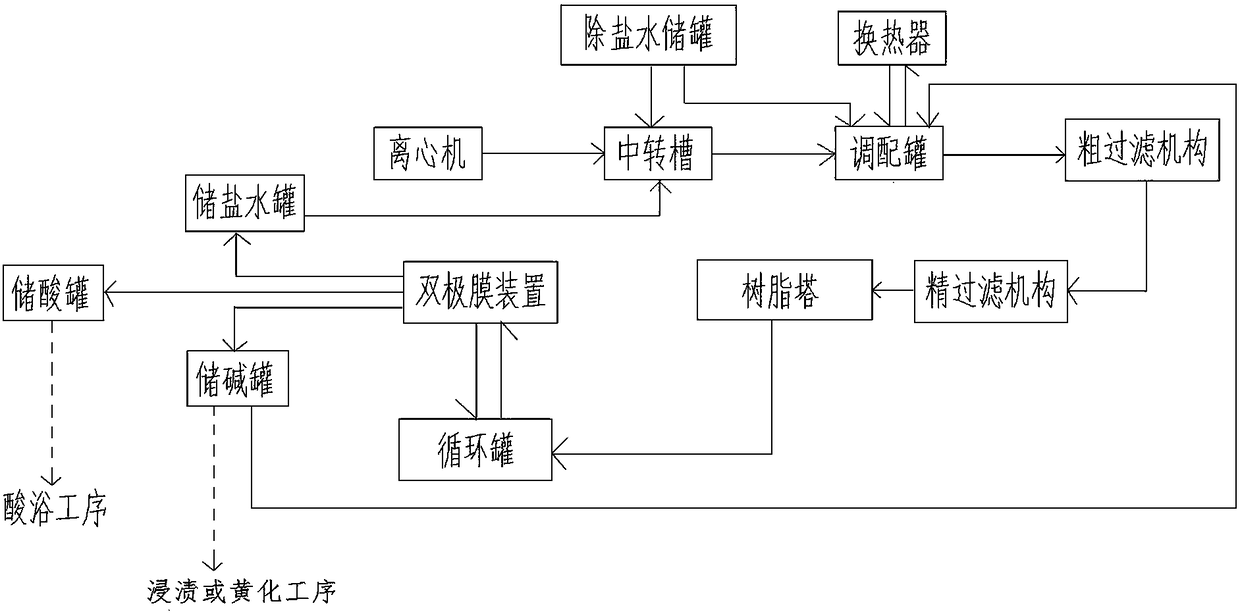

[0105] A recycling and environmental protection treatment process for viscose waste liquid,

[0106] After the viscose waste liquid is separated by the centrifuge 1, the powdery solid containing sodium sulfate, zinc sulfate and sulfuric acid and the concentrated acid bath containing sodium sulfate, zinc sulfate and sulfuric acid are obtained, and the concentrated acid bath is directly transported to the viscose through the pipeline. In the acid storage tank of the acid station in the rubber fiber production process, the powdery solids containing sodium sulfate, zinc sulfate and sulfuric acid are placed in the transfer tank 2;

[0107] By adding demineralized water into the transfer tank 2, the powdery solid is dissolved to obtain a solution;

[0108] Then, the dissolving solution is passed into the blending tank 3, and the temperature, pH and sodium sulfate concentration in the blending tank 3 are adjusted to obtain a solution containing suspended matter;

[0109] Under this ...

Embodiment 2

[0118] On the basis of embodiment 1, further,

[0119] Further, the viscose waste liquid includes sodium sulfate with a concentration of 200g / L, zinc sulfate with a concentration of 0.1g / L and sulfuric acid with a concentration of 5g / L;

[0120] The concentration of sodium sulfate in the lysate is 300g / L;

[0121] The sodium sulfate concentration control in the described deployment tank 3 is 300g / L;

[0122]Described acid solution is the sulfuric acid solution of concentration 60g / L, and after reverse osmosis, described concentrated sulfuric acid solution concentration is 110g / L, and described dilute sulfuric acid solution concentration is 10g / L;

[0123] Described lye is the sodium hydroxide solution that concentration is 45g / L; After nanofiltration membrane action, described sodium hydroxide solution concentration is 45g / L;

[0124] Described brine comprises the sulfuric acid solution that concentration is 20g / L and the sodium sulfate solution that co...

Embodiment 3

[0142] On the basis of embodiment 2, the difference of this embodiment is:

[0143] Further, the viscose waste liquid includes sodium sulfate with a concentration of 300g / L, zinc sulfate with a concentration of 1g / L and sulfuric acid with a concentration of 10g / L;

[0144] The concentration of sodium sulfate in the lysate is 300g / L;

[0145] The sodium sulfate concentration control in the described deployment tank 3 is 300g / L;

[0146] Described acid solution is the sulfuric acid solution of concentration 80g / L, and after reverse osmosis, described concentrated sulfuric acid solution concentration is 130g / L, and described dilute sulfuric acid solution concentration is 30g / L;

[0147] Described lye comprises the sodium hydroxide solution that concentration is 80g / L and the sodium sulfate solution that concentration is 2g / L; After nanofiltration membrane effect, described sodium hydroxide solution concentration is 80g / L, and sodium sulfate in mixed liquor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bursting strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com