Feeding device

A feeding device and feeding technology, applied in the direction of packaging, transportation, packaging, containers, etc., can solve the problems of high labor intensity, affecting the accuracy of blanking, and hindering materials, etc., and achieve good arch breaking effect, good arch breaking strength, The effect of flipping smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail through the following embodiments. However, those skilled in the art should understand that the following embodiments do not limit the protection scope of the present invention, and any improvements and changes made on the basis of the present invention are within the protection scope of the present invention.

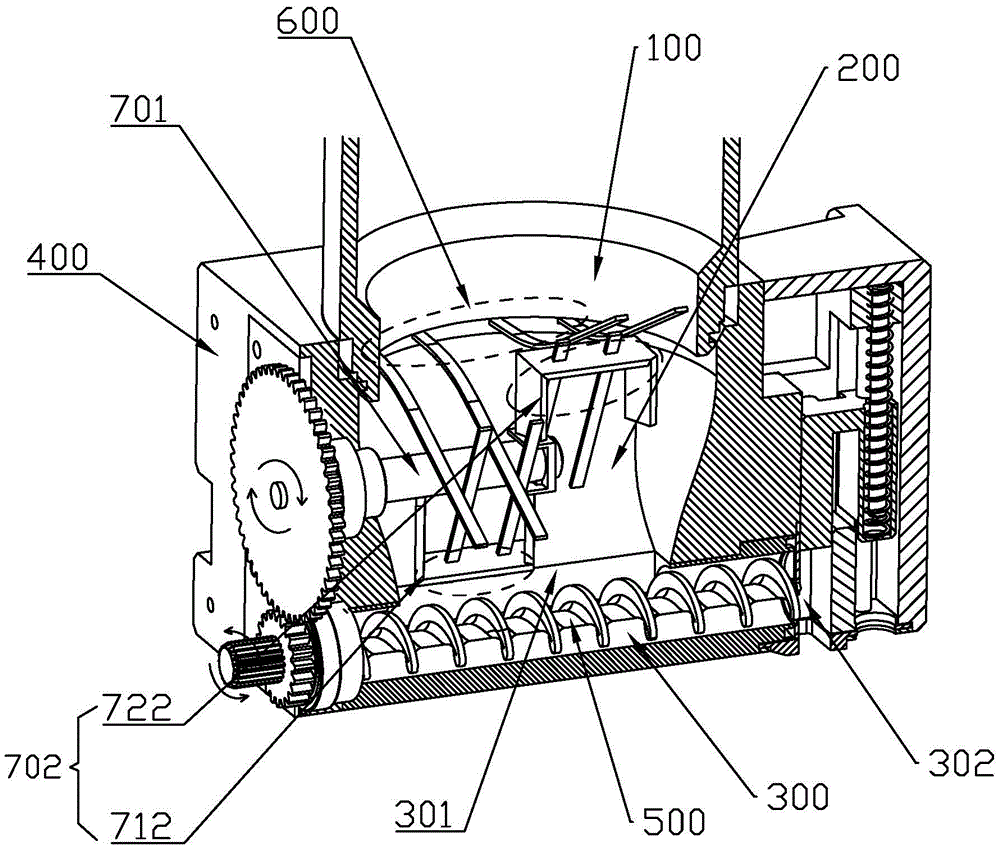

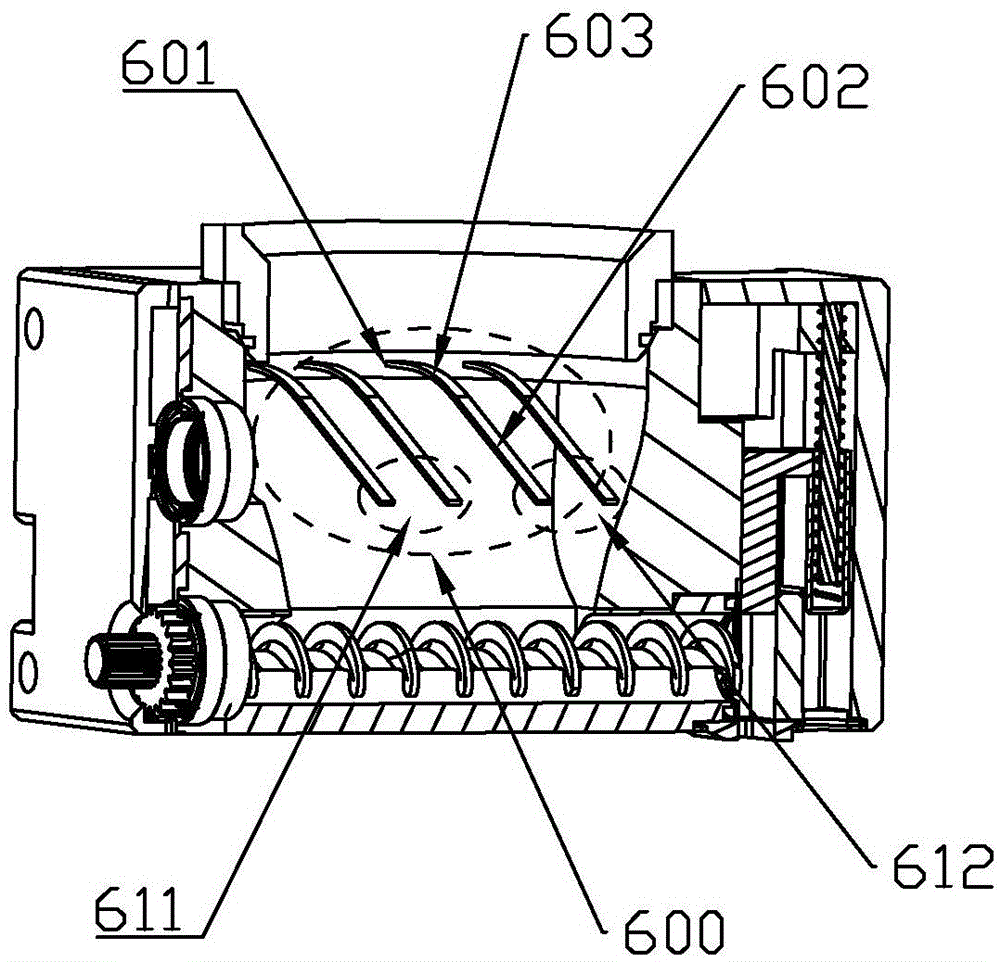

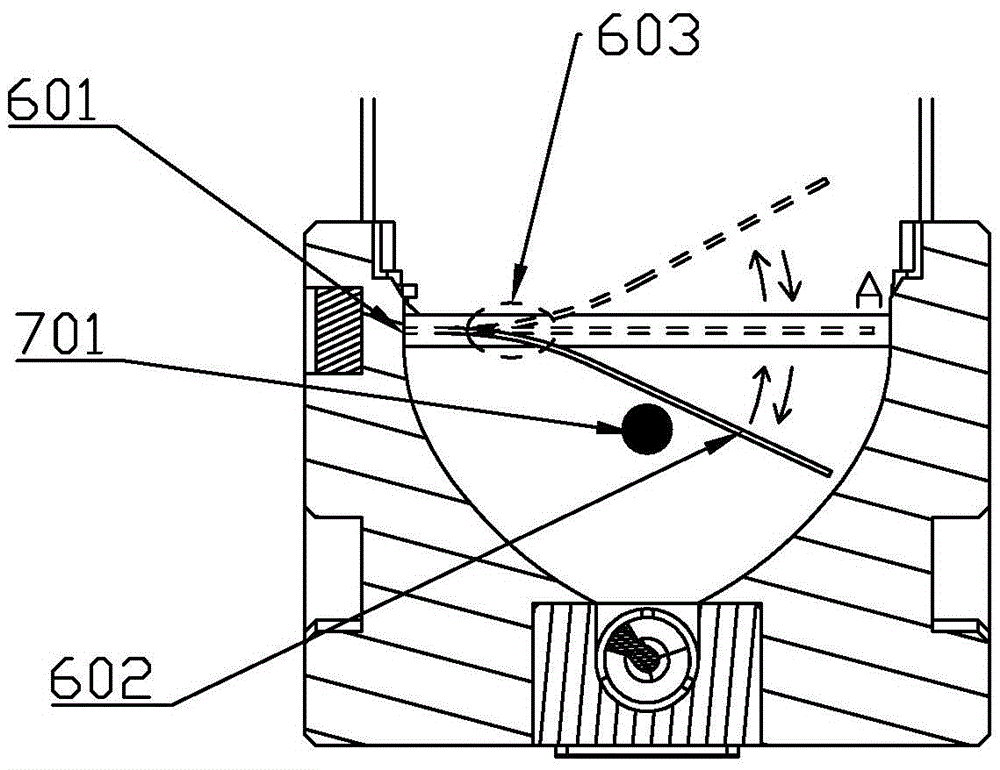

[0035] See attached figure 1 , the present invention discloses a feeding device, comprising a feed port 100, a stirring chamber 200 and a feeding chamber 300, wherein the feed port 100, the stirring chamber 200 and the feeding chamber 300 communicate with each other, wherein the stirring chamber 200 and The feeding chamber 300 is surrounded by the shell 400 . Specifically, the feeding port 100 is disposed above the stirring chamber 200 , and the feeding chamber 300 is disposed below the stirring chamber 200 . The upper part of the feeding port 100 can be used to cooperate with the storage container. Generally, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com