Rotary direct motion arch breaking device

A driving device and a technology for breaking arches, which are applied in the field of rotary direct-acting arch breaking devices and auxiliary equipment, can solve the problems such as the inability to completely eliminate the arching of roofing materials, affecting the normal progress of production, and the limited area of breaking arches, so as to improve the installation of equipment. Efficiency, conducive to on-site installation, the effect of eliminating workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

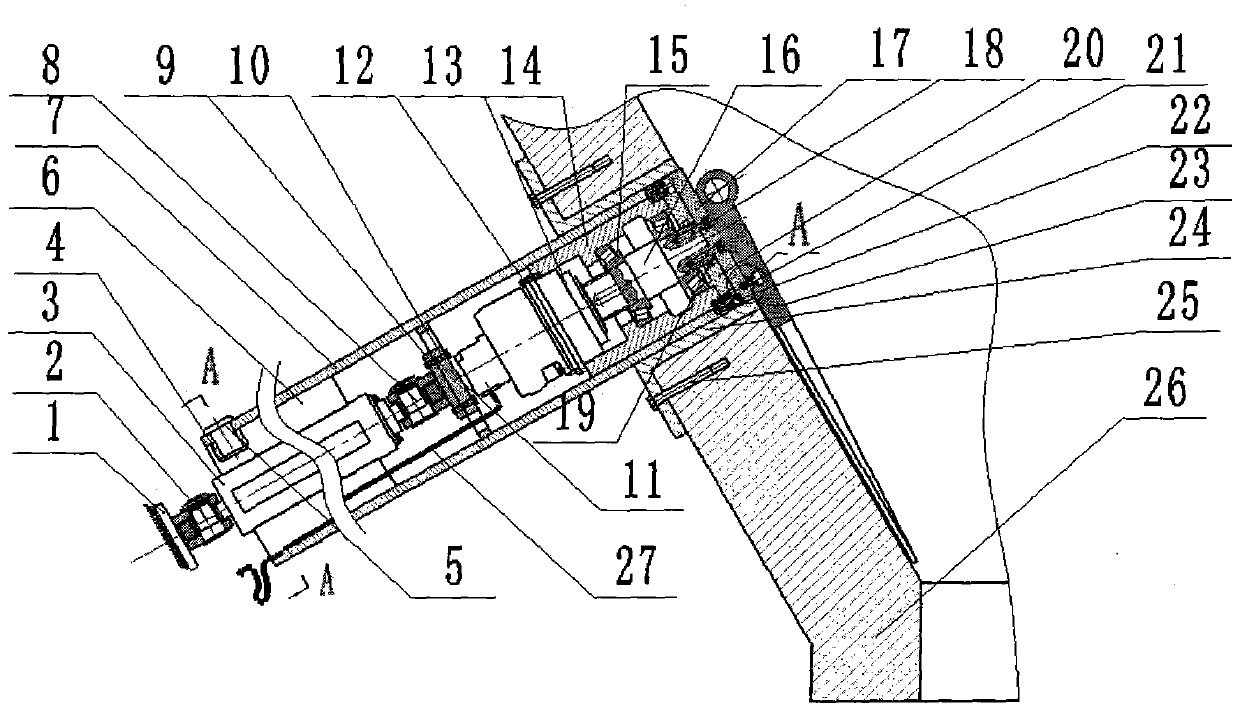

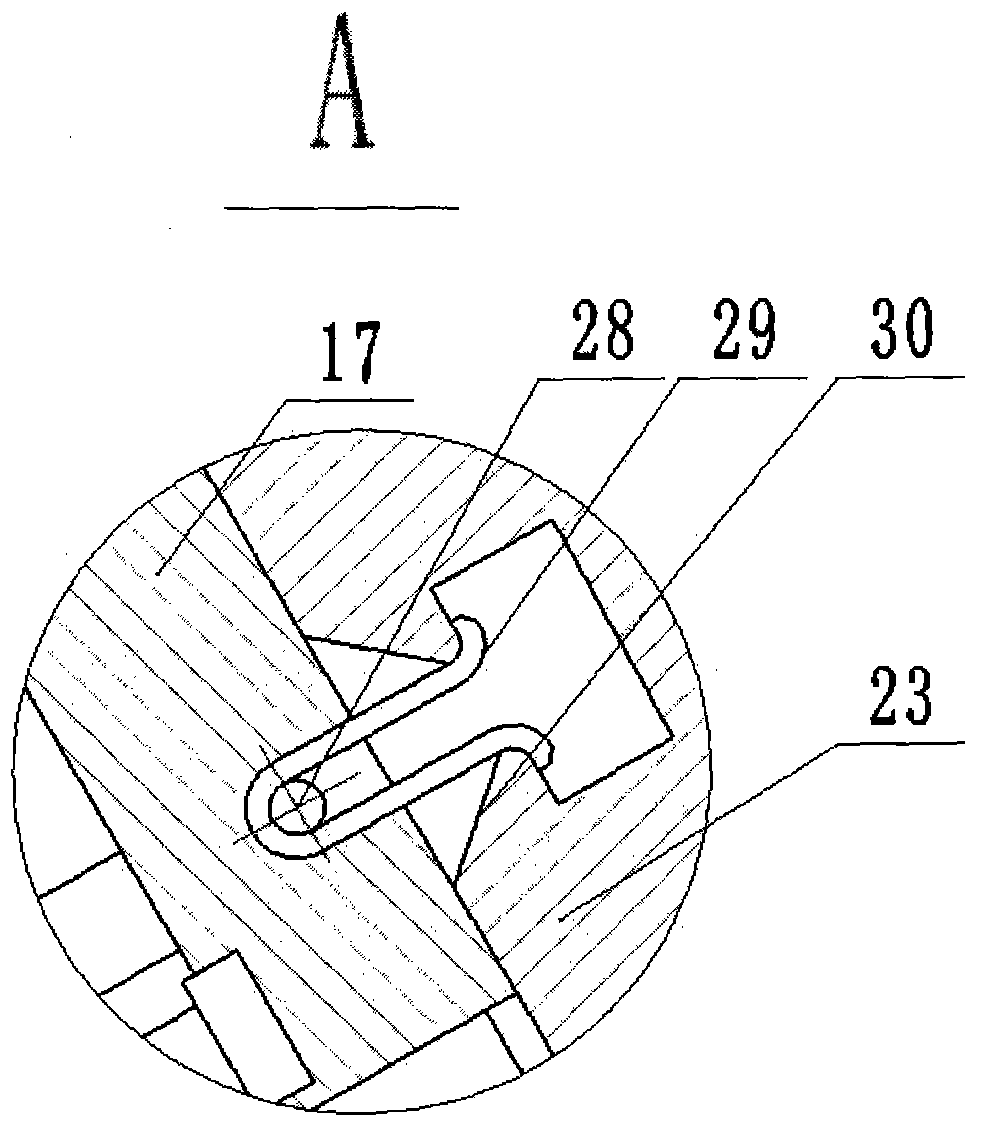

[0021] Embodiment one: see figure 1 , figure 2 , Figure 5 , the direct drive device adopts the oil cylinder 3, the oil cylinder is connected to the base 1 through the hinge shaft 2, and the outer wall of the oil cylinder barrel 38 is welded with three guide sliders 6 along the axial direction of the oil cylinder, the outer surface of the guide slider and the inner surface of the arch breaking sleeve 7 Sliding fit, oil cylinder piston rod 39 is connected on the connecting plate 11 with connecting bolt 10 through internal hinge shaft 8 and internal hinge shaft seat 9, and connecting plate is welded on the inner wall of the arch breaking sleeve. Use countersunk head screws 21 to connect the bearing chamber inside the upper end of the arch-breaking sleeve. The rotary drive device is driven by an oil motor 13 with a reduction mechanism. The oil motor is fixed on one end of the bearing chamber 14 with fastening bolts 12. The key is connected with the rotary shaft 16, and the rot...

Embodiment 2

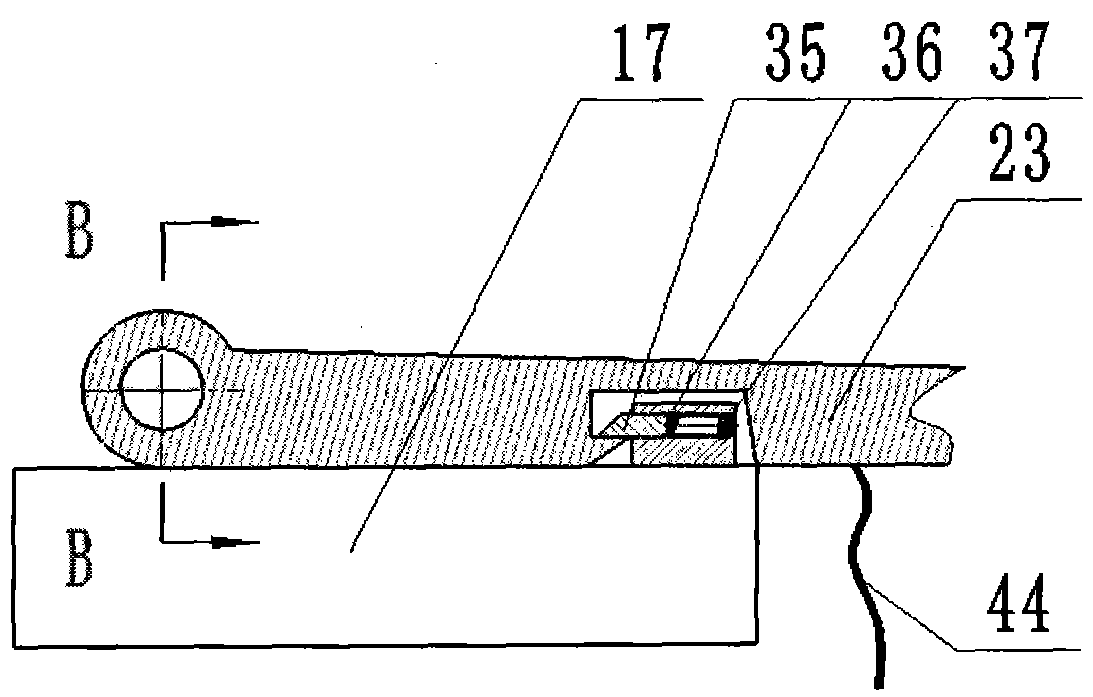

[0025] Embodiment two: see image 3 , Figure 4, In this embodiment, the swing locking device is composed of a locking pin 35, a pin seat 36 and a spring 37, etc., the pin seat is welded on the revolving cover, and a tapered slot 30 is provided on the distance-adding rod. When installing the arch-breaking device, the distance-adding rod is swung around the pin shaft by tightening the rope 44. After reaching a certain angle, when the locking pin enters the tapered slot on the distance-adding rod, the spring is compressed and finally enters the tapered clip. In the cavity on the top of the groove, the locking pin stretches out to lock the distance-adding bar on the revolving cover to prevent it from swinging. When disassembling, adjust the pressure of the hydraulic system to increase the retraction tension of the oil cylinder, and break the deadlock pin to disassemble the arch breaking sleeve and distance adding rod. When reinstalling, replace the deadlock pin to ensure that th...

Embodiment 3

[0026] Embodiment three: see Figure 6 , in this embodiment, a guide post is used, the end of the guide post is still fitted with a sliding wheel, and the sliding wheel is inserted between the two guide sliding blocks, which can also prevent the problem that the distance adding rod does not rotate when the oil motor is working .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com