Device for measuring and adjusting concentration of slurry solution

A technology of concentration measurement and adjustment device, applied in measurement device, sampling device, control/adjustment system, etc., can solve the problems of undetermined slurry concentration, singleness, hydrogen peroxide concentration measurement error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

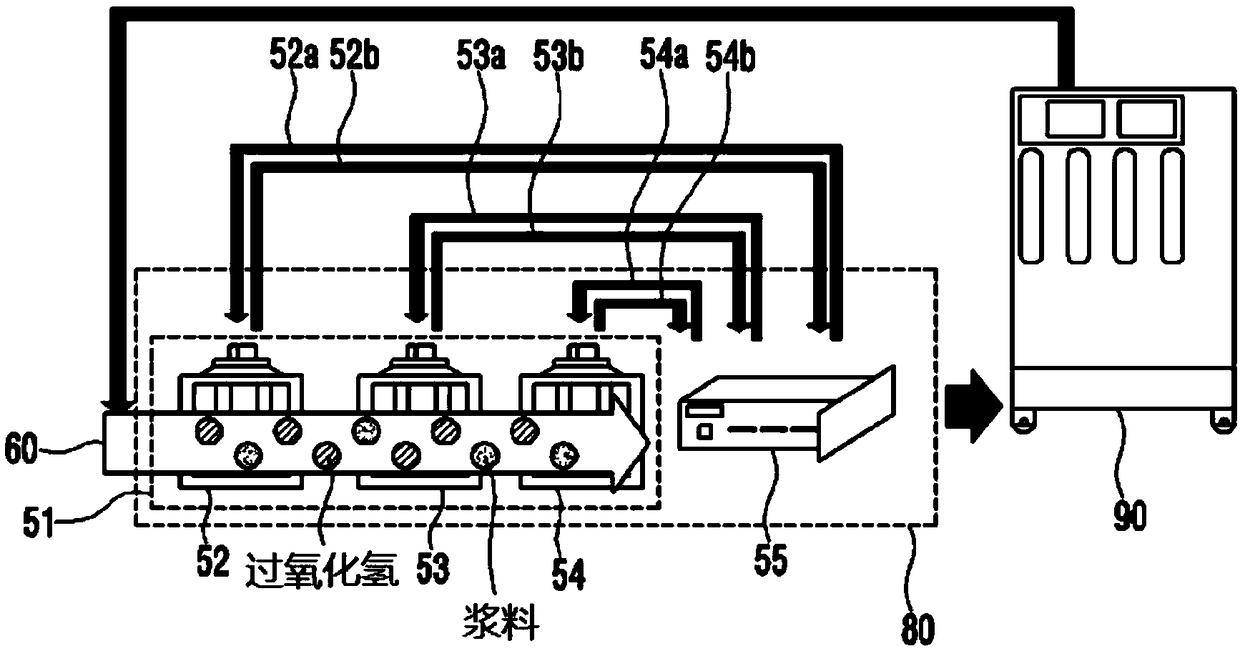

[0036] The slurry solution mainly used in the semiconductor CMP process contains two kinds of hydrogen peroxide and slurry. Hydrogen peroxide is primarily chemically reactive and cleansing. The slurry acts as a physical (mechanical) abrasive. The concentration of hydrogen peroxide in the slurry solution and the concentration of the slurry vary corresponding to the film on which the CMP process is performed. Especially in the case of slurry, not only the concentration of the slurry but also the kind of the slurry varies according to the CMP process. In this way, the concentration of hydrogen peroxide in the slurry solution used in CMP, the concentration of the slurry, and the type of the slurry vary.

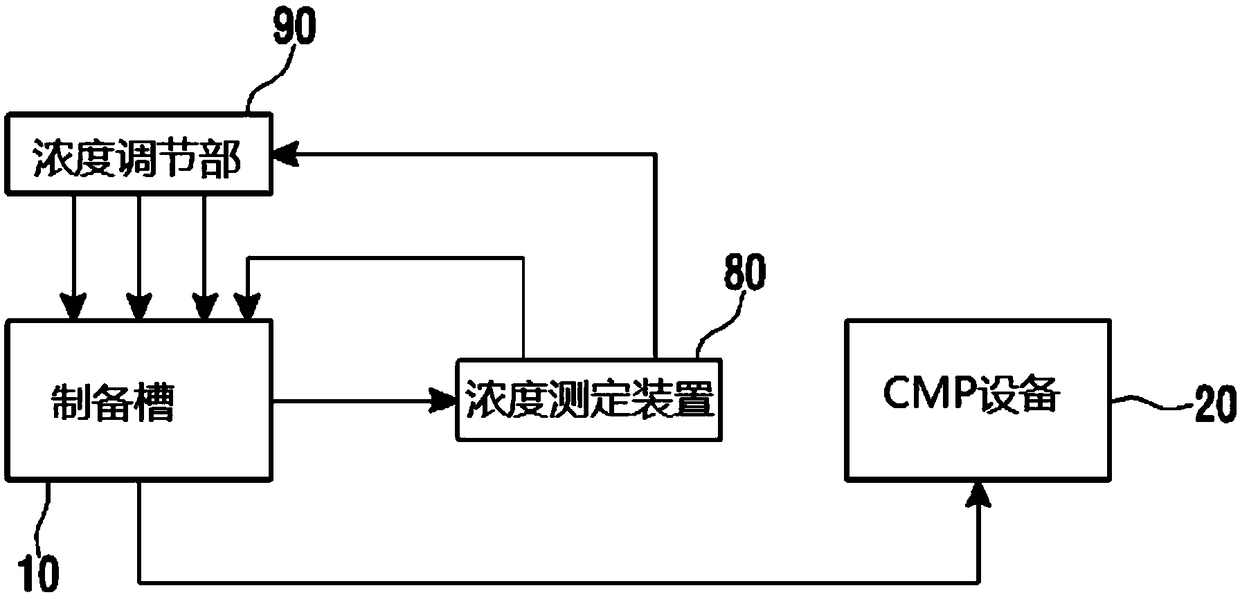

[0037] figure 1 It is a schematic diagram of a CMP process system to which a concentration measurement and adjustment device for a slurry solution according to an embodiment of the present invention is applied.

[0038] refer to figure 1 , the CMP process system to which the c...

no. 2 approach

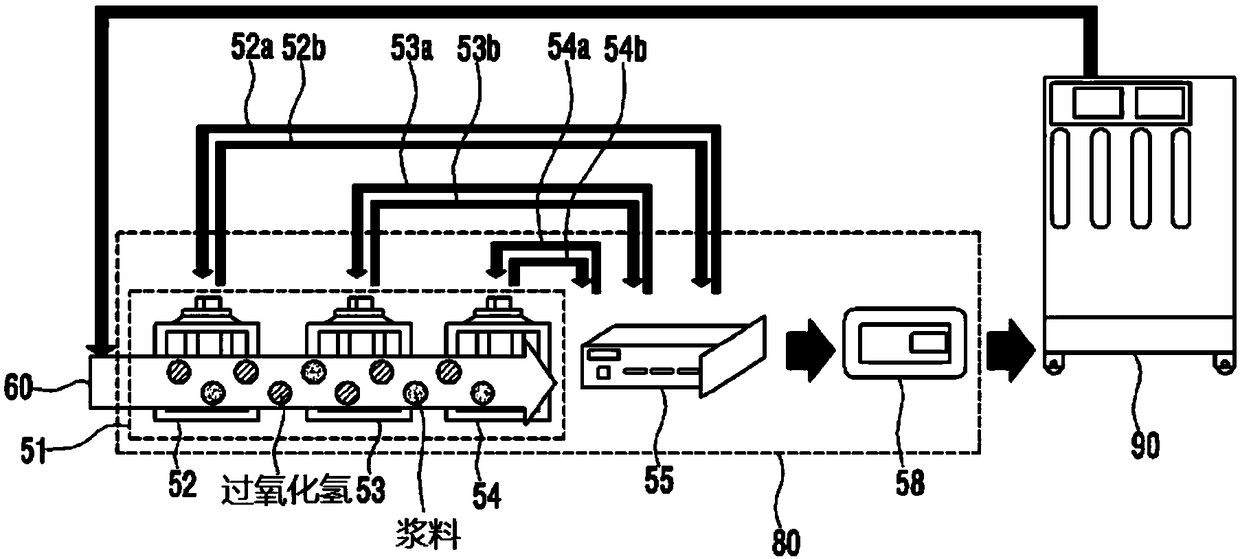

[0132] image 3 It is a schematic diagram of a concentration measuring device for a slurry solution and a concentration measuring and adjusting device for a slurry solution to which the concentration measuring device is applied according to a second embodiment of the present invention.

[0133] refer to figure 1 and image 3, The concentration measurement device 80 of a slurry solution according to the second embodiment includes a sensor unit 51 , a concentration measurement unit 55 , and a display unit 58 . The sensor unit 51 includes a first sensor 52 that measures the conductivity of the solution, a second sensor 53 that measures the velocity of ultrasonic waves in the solution, and a third sensor 54 that measures the absorbance of the solution. The concentration measurement unit 55 analyzes the electrical conductivity, ultrasonic propagation velocity, and absorbance input from the sensor unit 51 to measure the concentration of hydrogen peroxide in the solution and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com