Catalyst composition for preparing polyketone compound, palladium mixed catalyst system, method for preparing polyketone compound using same, and polyketone polymer

A technology for catalysts and compounds, applied in catalyst activation/preparation, organic compound/hydride/coordination complex catalysts, catalyst supports, etc., can solve the problems of difficulty in mass production process, low apparent density, scaling, etc. Achieve good stability and activity, high apparent density, and prevent scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0168] Preparation method of polyketone

[0169] Yet another embodiment of the present invention relates to a method for preparing polyketones, which is characterized in that it comprises: the step of dispersing a catalyst composition for preparing polyketides in a solvent; and adding olefin and carbon monoxide to carry out the polymerization step.

[0170] The preparation method of polyketone according to a specific embodiment has the above-mentioned carrier modified with sulfonic acid groups as a heterogeneous material mixed with a palladium-based catalyst, for example, it has the difference from the palladium-based catalyst loaded in the surface modified with sulfonic acid groups The state of the catalyst in the form of a permanent carrier, thereby, when applied to the polyketone polymerization process, etc., uniformly controls the shape and size of the finally prepared polyketone, thereby improving the apparent density of the polyketone and preventing The fouling phenom...

preparation example 1

[0199] Preparation example 1: preparation carries out the carrier of surface modification with sulfonic acid group

[0200] (Prepare carrier)

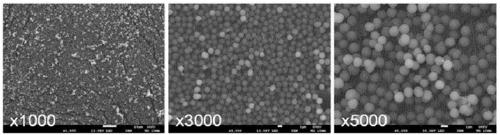

[0201] 500mL of methanol (Methanol), 90mL of H 2 0. 32 mL of ammonium hydroxide solution (Ammonium hydroxide solution) and 1.2 g of hexadecyltrimethyl ammonium bromide (CTAB) were sequentially added to a 1 L beaker and stirred at 300 RPM for 30 minutes. While stirring at 300 RPM, Tetraethyl orthosilicate (TEOS) was added. While stirring at 300 RPM, react at room temperature for 24 hours. The synthesized silica (Silica) was separated with a centrifuge, washed with methanol and dried in an oven. The dried silica was then calcined at 550 °C for 5 hours. The prepared calcined silica was finely ground in a mortar and heated at 850° C. for 12 hours in an Ar furnace to prepare a support.

[0202] benzyl magnesium chloride was added to the silica carrier prepared above, and stirred at room temperature in a nitrogen atmosphere to generate ...

preparation example 2

[0205] Preparation example 2: preparation carries out the carrier of surface modification with sulfonic acid group

[0206] (Prepare carrier)

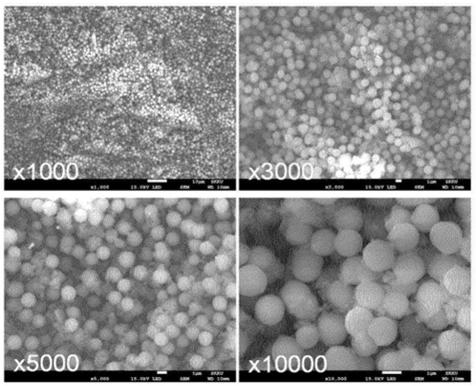

[0207] Zinc nitrate hexahydrate (Zinc nitrate hexahydrate, 1eq, 0.1mol, 297.49g / mol, 29.75g) was dissolved in 500mL of methanol to prepare zinc nitrate solution (Zinc nitrate solution), hexadecyltrimethyl bromide Ammonium bromide (Hexadecyltrimethyl ammonium bromide; CTAB, 99+%, 0.25 eq, 0.025 mol, 364.45 g / mol, 9.1 g) was dissolved in 125 mL of methanol to prepare a solution (CTAB solution). And, 2-methylimidazole (4eq, 0.4mol, 82.10g / mol, 32.84g) was dissolved in 500 mL of methanol to prepare a solution (2-methylimidazole solution).

[0208] Add 100mL of zinc nitrate solution prepared above into 250mL of RB (5 pieces), add 20mL of CTAB solution and 100mL of 2-methylimidazole solution sequentially while stirring at 1100rpm, and stir for 5 minutes. Thereafter, stirring was stopped, and the mixture was allowed to stand (room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com