Ceramic aluminum-clad aluminum-copper plate, method for fabricating same, heat dissipating component, and IGBT module

A technology for heat dissipation components and aluminum cladding is applied in the fields of ceramic aluminum clad copper plates and their preparation, heat dissipation components and IGBT modules. Achieve high connection strength and heat conduction efficiency, high yield and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

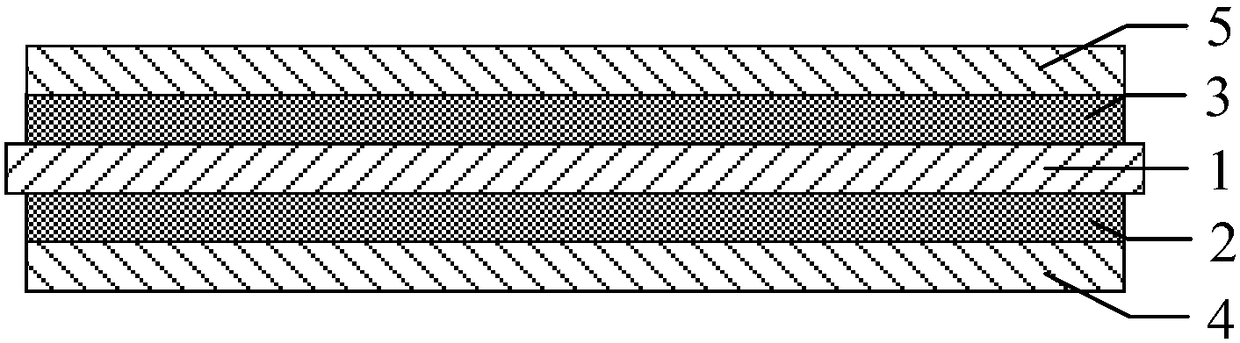

[0033] The second aspect of the present disclosure provides a method for preparing a ceramic aluminum-copper clad laminate, the method comprising the following steps:

[0034] S1. Put the ceramic insulating board 1, the first copper layer 4, and the second copper layer 5 into the aluminized mold 11, and make a first gap between the ceramic insulating board 1 and the first copper layer 4 9 and there is a second gap 10 between the ceramic insulating board 1 and the second copper layer 5;

[0035] S2. Under pressure casting infiltration conditions, molten aluminum is added to the aluminized mold 11 and filled into the first void 9 and the second void 10 and vacuumized and pressurized, and then cooled demoulding;

[0036] S3. Removing part of the aluminum metal in the first gap 9 and the second gap 10 by etching, so that the remaining aluminum metal in the first gap 9 forms the first aluminum layer 2 and the second gap 10 The remaining aluminum metal in forms the second aluminum...

Embodiment 1

[0047] This example is used to illustrate the preparation method of the ceramic aluminum-copper clad laminate.

[0048] Alumina ceramic insulating board 1 with a thickness of 0.38mm, a length of 67mm, and a width of 61mm, a first copper layer with a thickness of 0.3mm, a length of 67mm, and a width of 61mm 4, a thickness of 0.3mm, a length of 67mm, and a width of 61mm The second copper layer 5 is packed into the aluminized mold 11; the center of the first copper layer 4, the second copper layer 5 and the ceramic insulating plate 1 is on a straight line, and makes the ceramic insulating plate 1 and the first There is a first gap 9 of 0.05 mm between the copper layers 4 and a second gap 10 of 0.05 mm between the ceramic insulating board 1 and the second copper layer 5 .

[0049] Preheat the aluminized mold 11 to a temperature of 600°C, add molten aluminum at 700°C to the aluminized mold 11, vacuumize the aluminized mold 11 to a pressure of 80Pa, and then pressurize to a pressure...

Embodiment 2

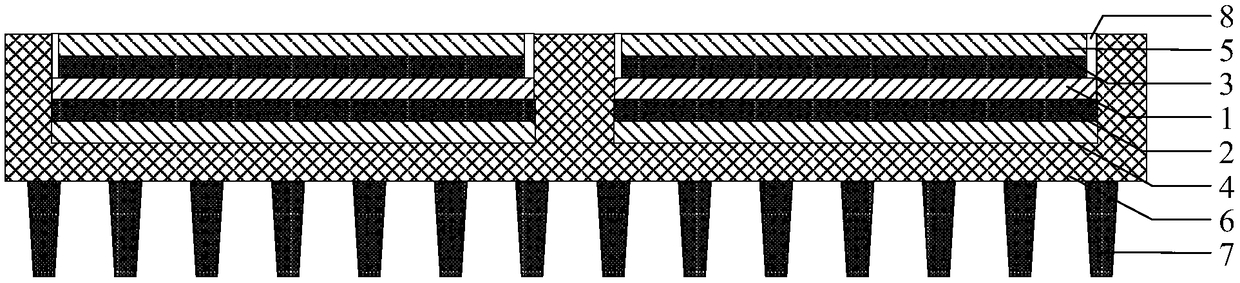

[0053] This embodiment is used to illustrate the preparation method of the heat dissipation element including the ceramic aluminum-copper clad laminate.

[0054] Toughened alumina ceramic insulating board 1 with a thickness of 0.32 mm, a length of 67 mm, and a width of 61 mm, a first copper layer with a thickness of 0.3 mm, a length of 67 mm, and a width of 61 mm 4, a thickness of 0.3 mm, a length of 67 mm, and a width of Put the second copper layer 5 of 61mm into the aluminized mold 11; the center of the first copper layer 4, the second copper layer 5 and the ceramic insulating plate 1 is in a straight line, and make the ceramic insulating plate 1 and the There is a first gap 9 of 0.05 mm between the first copper layers 4 and a second gap 10 of 0.05 mm between the ceramic insulating board 1 and the second copper layer 5 .

[0055] Preheat the aluminized mold 11 to a temperature of 600°C, add molten aluminum at 700°C to the aluminized mold 11, vacuumize the aluminized mold 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com