Electroplating post-processing process for silver-plate copper wire

A silver-plated copper wire and post-processing technology, which is applied in the direction of metal material coating process, superimposed layer plating, coating, etc., can solve the problems of easy discoloration, loss of luster, and difficulty in removing the color of the silver-plated layer, etc., to achieve The effect of enhancing anti-corrosion ability and preventing the generation of sulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

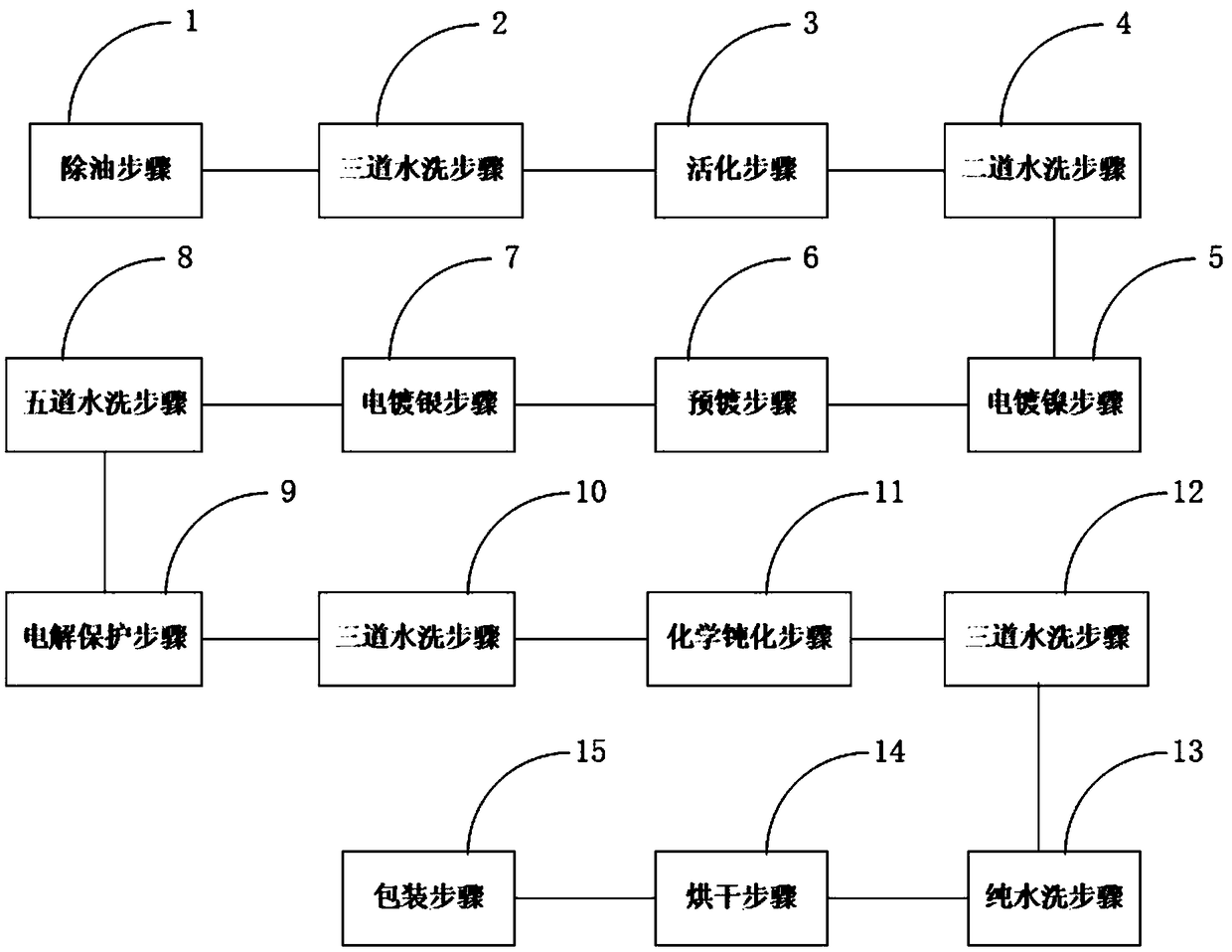

Method used

Image

Examples

Embodiment 1

[0084] In this embodiment, a copper wire with a wire diameter of 0.78 mm is selected. Proceed as follows:

[0085] 1. Degreasing step

[0086] The degreasing solution includes the following components in parts by weight: 5 parts of electrolytic degreasing agent, 0.1 part of sodium hydroxide and 40 parts of pure water, the electrolysis current is 1A, and the temperature is 60°C.

[0087] 2. Three washing steps

[0088] 3. Activation step

[0089] The activation solution includes the following components: 1.8L of concentrated hydrochloric acid, 150g of sulfamic acid and 30L of pure water.

[0090] 4. Second washing step

[0091] 5. Nickel plating step

[0092] The nickel plating solution contains components at the following concentrations: 300g / L nickel sulfamate, 7g / L nickel chloride and 40g / L boric acid; the nickel electroplating current is 5A, and the temperature is 50°C.

[0093] 6. Pre-plating step

[0094] The pre-plating silver solution contains the following compo...

Embodiment 2

[0108] In this embodiment, a copper wire with a wire diameter of 1.0 mm is selected. Proceed as follows:

[0109] 1. Degreasing step

[0110] The degreasing solution includes the following components by weight: 6 parts of electrolytic degreasing agent, 0.2 parts of sodium hydroxide and 45 parts of pure water, the electrolysis current is 2A, and the temperature is 62°C.

[0111] 2. Three washing steps

[0112] 3. Activation step

[0113] The activation solution includes the following components: 1.85L of concentrated hydrochloric acid, 180g of sulfamic acid and 32L of pure water.

[0114] 4. Second washing step

[0115] 5. Nickel plating step

[0116] The nickel plating solution contains components at the following concentrations: 320g / L nickel sulfamate, 9g / L nickel chloride and 42g / L boric acid; the nickel plating current is 10A, and the temperature is 52°C.

[0117] 6. Pre-plating step

[0118] The pre-silvering solution contains the following components by volume: 60...

Embodiment 3

[0132] In this embodiment, a copper wire with a wire diameter of 1.15 mm is selected. Proceed as follows:

[0133] 1. Degreasing step

[0134] The degreasing solution includes the following components in parts by weight: 7 parts of electrolytic degreasing agent, 0.4 parts of sodium hydroxide and 50 parts of pure water, the electrolysis current is 5A, and the temperature is 65°C.

[0135] 2. Three washing steps

[0136] 3. Activation step

[0137] The activation solution includes the following components: concentrated hydrochloric acid 1.9L, sulfamic acid 200g and pure water 35L.

[0138] 4. Second washing step

[0139] 5. Nickel plating step

[0140] The nickel plating solution contains components at the following concentrations: 350g / L nickel sulfamate, 10g / L nickel chloride and 45g / L boric acid; the nickel plating current is 20A, and the temperature is 55°C.

[0141] 6. Pre-plating step

[0142] The pre-plating solution contains the following components by volume: 80 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com