Method for preparing magnesium alloy surface micro-nano structure hydroxyapatite coating through hydrothermal manner

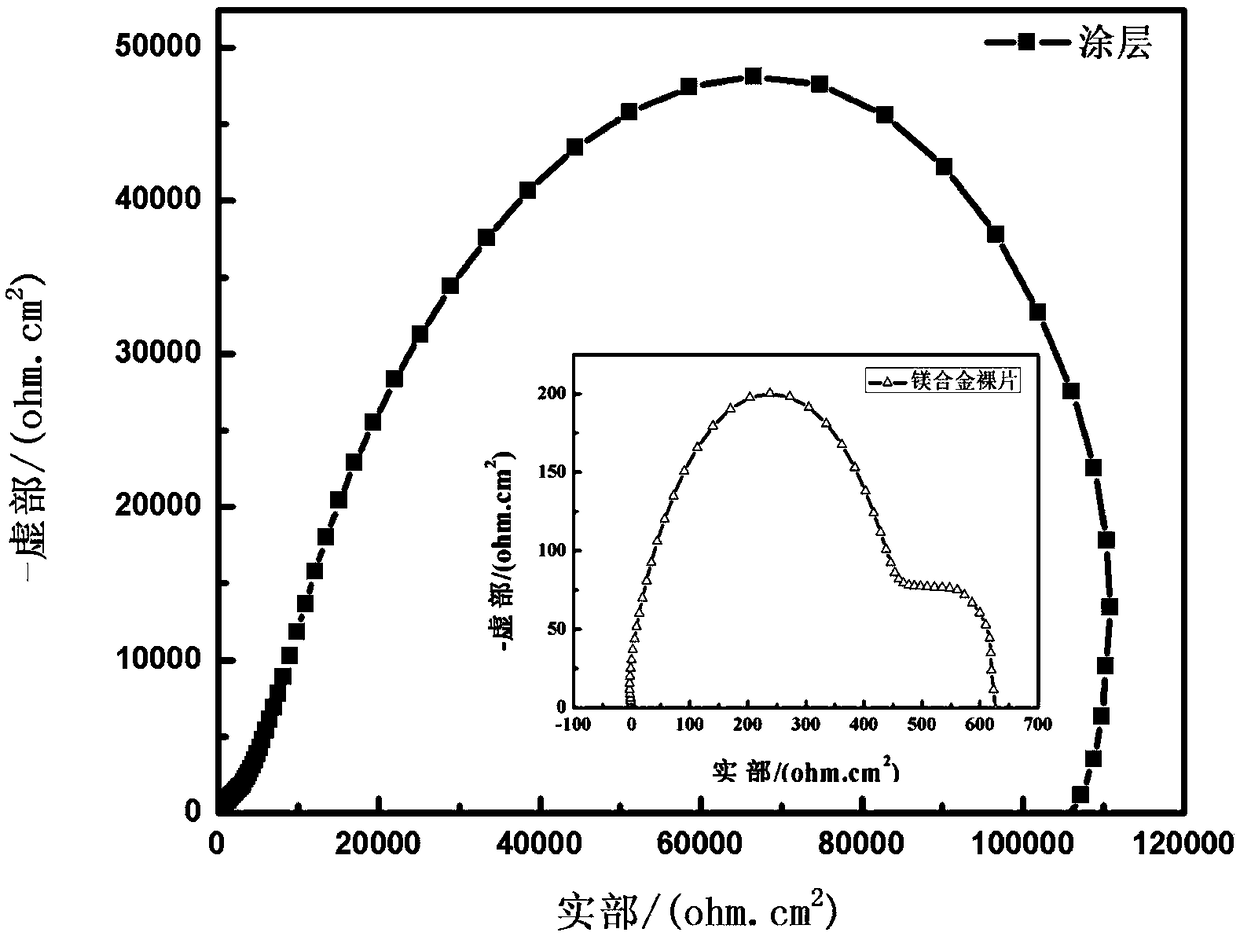

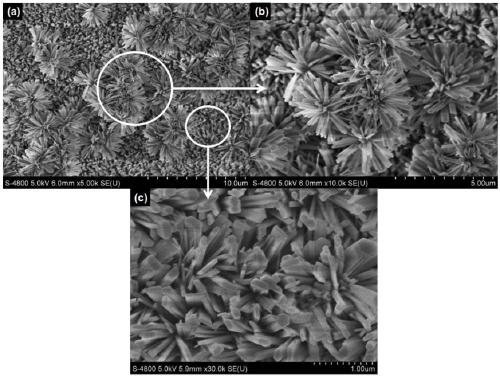

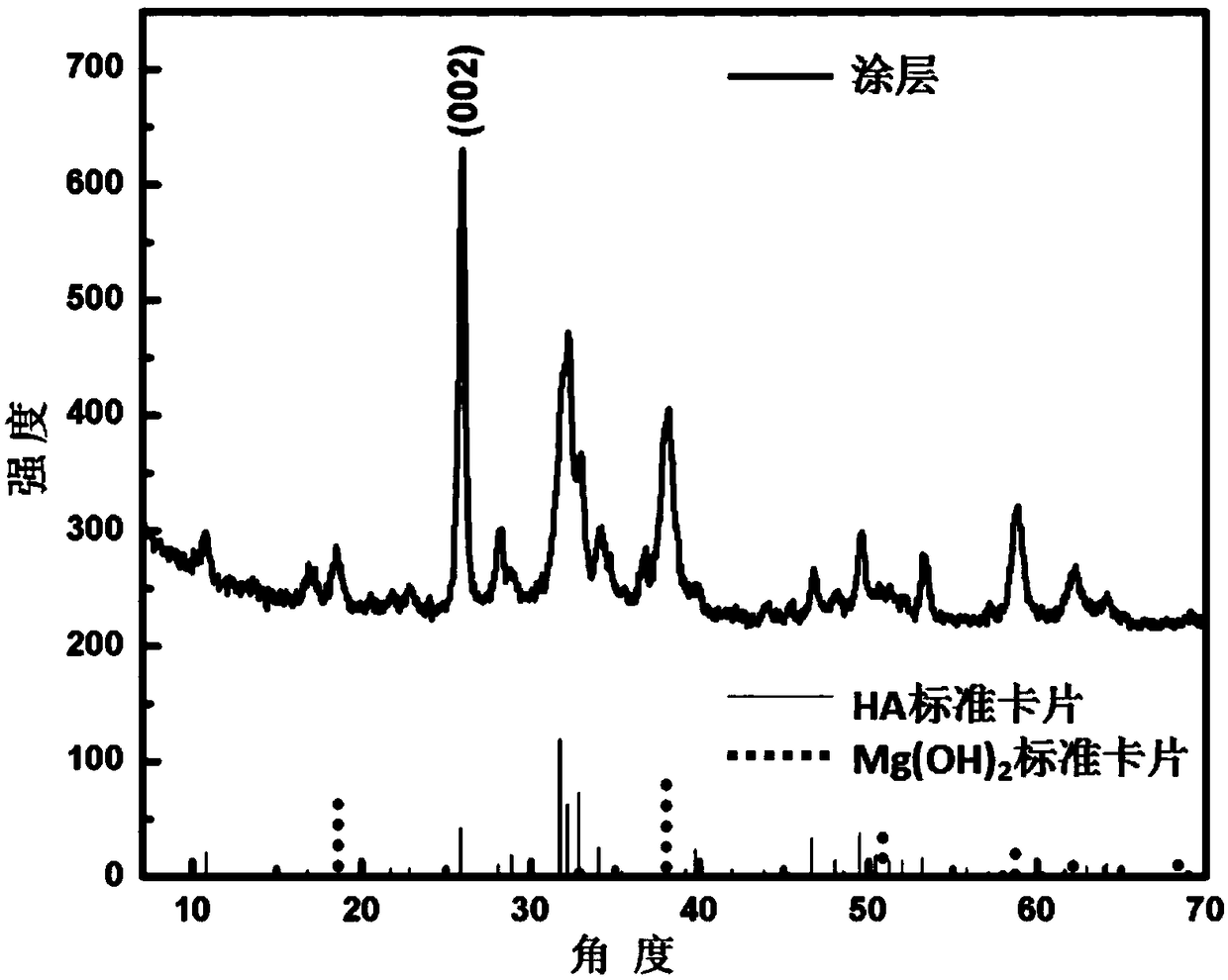

A technology of hydroxyapatite and micro-nano structure, which is applied in the direction of coating, etc., to achieve the effects of good short-term corrosion resistance, good biological activity, and great commercial promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Process the AZ31 magnesium alloy into a block of 10mm×10mm×2mm, and use 800 # , 1200 # , 2000 # Polished with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water, and ethanol for 10 minutes, and dried with hot air.

[0037] (2) Prepare 25 mL of NaOH solution with a concentration of 1.5 mol / L. Soak the polished magnesium alloy in the solution and keep it warm at 80°C for 1 hour, then wash the magnesium alloy sample with deionized water and dry it.

[0038] (3) With EDTA2NaCa as Ca source, KH 2 PO 4 Add distilled water to prepare the solution for the P source in turn; then use 2mol / L NaOH solution to adjust the pH value of the mixed solution to 9, and magnetically stir for 1h; wherein, the Ca in the mixed solution 2+ Concentration and PO 4 3- The concentration of each is 0.20mol / L, and 75ml of the solution is measured and poured into the autoclave.

[0039] (4) Put the NaOH-treated magnesium alloy sample into a high-pressure reaction kettle ...

Embodiment 2

[0042] (1) Process the AZ31 magnesium alloy into a block of 10mm×10mm×2mm, and use 800 # , 1200 # , 2000 # Polished with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water, and ethanol for 10 minutes, and dried with hot air.

[0043] (2) Prepare 25 mL of NaOH solution with a concentration of 1.5 mol / L. Soak the polished magnesium alloy in the solution and keep it warm at 80°C for 1 hour, then wash the magnesium alloy sample with deionized water and dry it.

[0044] (3) With EDTA2NaCa as Ca source, NaH 2 PO 4 Add distilled water to prepare the solution for the P source in turn; then use 2mol / L NaOH solution to adjust the pH value of the mixed solution to 9, and magnetically stir for 1h; wherein, the Ca in the mixed solution 2+ Concentration and PO 4 3- The concentration is 0.2mol / L.

[0045] (4) Put the NaOH-treated magnesium alloy sample into a high-pressure reaction kettle filled with reagents, put the reaction kettle into an oven at 100°C for 48 h...

Embodiment 3

[0048] (1) Process the AZ31 magnesium alloy into a block of 10mm×10mm×2mm, and use 800 # , 1200 # , 2000 # Polished with SiC sandpaper, then ultrasonically cleaned in acetone, deionized water, and ethanol for 10 minutes, and dried with hot air.

[0049] (2) Prepare 25 mL of NaOH solution with a concentration of 1.5 mol / L. Soak the polished magnesium alloy in the solution and keep it warm at 80°C for 1 hour, then wash the magnesium alloy sample with deionized water and dry it.

[0050] (3) With EDTA2NaCa as Ca source, (NH 4 ) 2 HPO 4 Add distilled water to prepare the solution for the P source in turn; then use 2mol / L NaOH solution to adjust the pH value of the mixed solution to 9, and magnetically stir for 1h; wherein, the Ca in the mixed solution 2+ The concentration is 0.25mol / L, PO 4 3- The concentration of the solution is 0.1mol / L, and 75ml of the solution is measured and poured into the autoclave.

[0051] (4) Put the NaOH-treated magnesium alloy sample into a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ac impedance | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

| Ac impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com