High-strength and toughness non-quenched and tempered steel and preparation method thereof

A technology of non-quenched and tempered steel with high strength and toughness, which is applied in the field of high-strength and toughness non-quenched and tempered steel and its preparation. , Improve the strength and toughness, strengthen the effect of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Specifically, the preparation method of high-strength toughness non-quenched and tempered steel may include the following steps:

[0046] Step 1: Using a vacuum induction furnace to smelt high-strength toughness non-quenched and tempered steel raw materials to obtain alloy ingots.

[0047] Step 2: Forge the alloy ingot into a Φ90mm round bar, change the Φ90mm round bar into a Φ40mm round bar, the initial forging temperature is higher than 1150°C, and the final forging temperature is between 840-1000°C;

[0048] Specifically, the initial forging temperature is 1180-1200°C, and the final forging temperature is between 860-950°C.

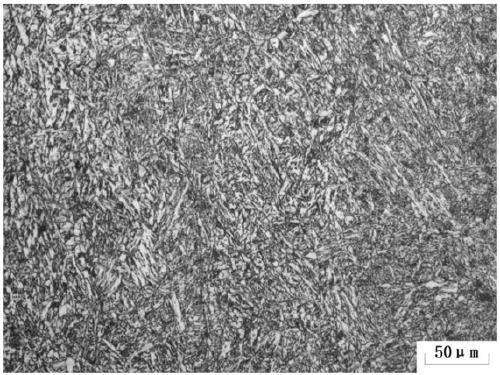

[0049] Step 3: Cool the forged bar to 700-750°C in air, and then cool it to below 450°C at a cooling rate of 1-2°C / s to obtain a uniform bainite structure.

Embodiment 1

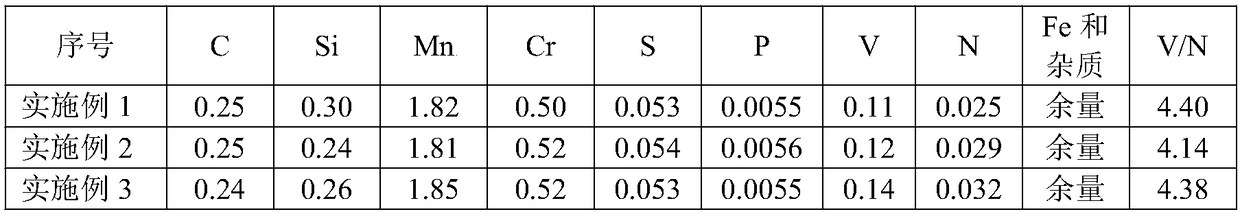

[0051] This embodiment provides a high-strength toughness non-quenched and tempered steel, including: C: 0.25%; Si: 0.30%; Mn: 1.82%; Cr: 0.50%, S: 0.053%; P: 0.0055%; V: 0.11%; N: 0.025%; V / N: 4.40, the rest is iron and unavoidable impurities.

[0052] The preparation method of this non-quenched and tempered steel is as follows:

[0053] (1) Smelting: use a vacuum induction furnace to smelt the raw materials of high-strength toughness non-quenched and tempered steel to obtain alloy ingots.

[0054] (2) Forging: Forge the alloy ingot into a Φ90mm round bar, change the Φ90mm round bar into a Φ40mm round bar, the initial forging temperature is 1190°C, and the final forging temperature is 880°C.

[0055] (3) Controlled cooling after forging: Cool the forged bar to 700-750°C in the air, and then cool it to below 450°C at a cooling rate of 1-2°C / s.

Embodiment 2

[0057] This embodiment provides a high-strength toughness non-quenched and tempered steel, which includes, by mass percentage: C: 0.25%; Si: 0.24%; Mn: 1.81%; Cr: 0.52%, S: 0.054%; P: 0.0056%; V: 0.12%; N: 0.029%; V / N: 4.14, and the balance is iron and unavoidable impurities.

[0058] The preparation method of this non-quenched and tempered steel is as follows:

[0059] (1) Smelting: use a vacuum induction furnace to smelt the raw materials of high-strength toughness non-quenched and tempered steel to obtain alloy ingots.

[0060] (2) Forging: Forge the alloy ingot into a Φ90mm round bar, change the Φ90mm round bar into a Φ40mm round bar, the initial forging temperature is 1200°C, and the final forging temperature is 885°C.

[0061] (3) Controlled cooling after forging: Cool the forged bar to 700-750°C in the air, and then cool it to below 450°C at a cooling rate of 1-2°C / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com