High-toughness corrosion-resistant biological magnesium alloy and preparation method thereof

A magnesium alloy and corrosion-resistant technology, which is applied in the field of high-strength, toughness, and corrosion-resistant bio-magnesium alloys and their preparation, can solve problems such as high production costs and magnesium alloy ablation, and achieve low cost, reduced grain size, and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

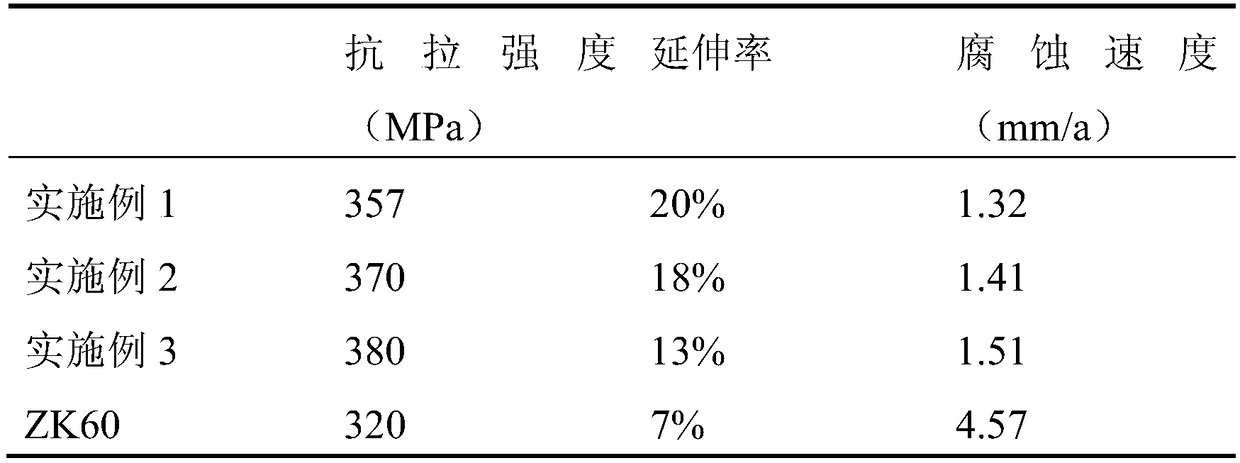

Embodiment 1

[0020] By weight percentage, the composition of magnesium alloy is Zn4%, Ca1.5%, Ti 0.4%, and the rest is Mg. The preparation process is as follows:

[0021] (1) Prepare the raw materials according to the furnace load of 20Kg, add the pure magnesium ingot into the electromagnetic induction furnace, and melt the pure magnesium under the protection of the flux; when the melt temperature reaches 710 ℃, add the Mg-40%Ca master alloy Add it in batches until it is completely melted. After stirring, heat the melt to reach 730°C, and then add Zn 78.2 Mg 17.2 Ti 4.6 After the master alloy is completely melted, it is stirred, kept for 20 minutes, and cooled in CO. 2 +SF 6 The mixed gas protective atmosphere injects the melt into the inflow funnel of spray deposition.

[0022] (2) Select nitrogen as the atomizing gas, the deposition process parameters are: the atomizing pressure is 0.8MPa, the magnesium alloy melt flow rate is 6Kg / min, and the atomizing gas flow rate is 15Nm 3 / min,...

Embodiment 2

[0025] By weight percentage, the composition of magnesium alloy is: Zn 6%, Ca 2%, Ti 0.2%, and the rest is Mg. The preparation process is as follows:

[0026] (1) Prepare the raw materials according to the furnace load of 25Kg, add the pure magnesium ingot into the electromagnetic induction furnace, and melt the pure magnesium under the protection of the flux; when the melt temperature reaches 700 ℃, add the Mg-30%Ca master alloy Add in batches until completely melted, heat the melt to 740°C after stirring, and then add Zn 77 Mg 20 Ti 3 After the master alloy is completely melted, it is stirred, kept for 20 minutes, and cooled in CO. 2 +SF 6 The mixed gas protective atmosphere injects the melt into the inflow funnel of spray deposition.

[0027] (2) Select nitrogen as the atomizing gas, the deposition process parameters are: the atomizing pressure is 0.7MPa, the magnesium alloy melt flow rate is 7Kg / min, and the atomizing gas flow rate is 20Nm 3 / min, the magnesium alloy ...

Embodiment 3

[0030] By weight percentage, the magnesium alloy composition is: Zn 8%, Ca 3%, Ti 0.5%, and the rest is Mg. The preparation process is as follows:

[0031] (1) Prepare the raw materials according to the furnace load of 25Kg, add the pure magnesium ingot into the electromagnetic induction furnace, and melt the pure magnesium under the protection of the flux; when the melt temperature reaches 720 ℃, add the Mg-40%Ca master alloy Add in batches until completely melted, and heat the melt to 740°C after stirring, then add Mg-Zn alloy and Zn 77 Mg 20 Ti 3 After the master alloy is completely melted, it is stirred with tools until it is uniform, and the melt is poured into the guide funnel for spray deposition under the protective atmosphere of argon gas.

[0032] (2) Select nitrogen as the atomizing gas, the deposition process parameters are: the atomizing pressure is 0.8MPa, the magnesium alloy melt flow rate is 8Kg / min, and the atomizing gas flow rate is 15Nm 3 / min, the compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com