Highly active gellan gum oligosaccharide producing bacteria and use thereof

A technology of gellan gum and gum oligosaccharide, applied in the directions of bacteria, microorganisms, microorganisms, etc., can solve the problems of difficult control of oxidative degradation method, difficult separation and purification of oligosaccharide products, wide molecular weight distribution of polysaccharides, etc. The effect of high antioxidant activity and strong cleavage activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

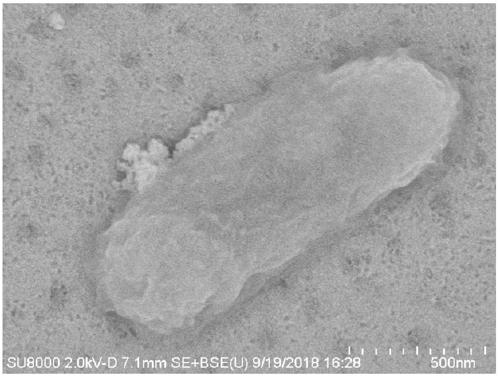

[0016] Embodiment 1, Pseudomonas alternata PE2 (highly active gellan gum oligosaccharide producing bacteria PE2):

[0017] The screening method is as follows: configure the improved MM basic screening medium, use gellan gum as the only carbon source and coagulant, dissolve 1 g of seaweed sample in 9 ml of sterile water, spread it on the plate, and culture it in the incubator at 30°C. By decomposing gellan gum, obvious holes will be produced on the plate, and the formed strains produced by screening have the ability to crack and use gellan gum. Among them, the most obvious cavity in the plate is Pseudomonas alternata PE2 (highly active gellan gum oligosaccharides). Sugar producing bacteria PE2).

[0018] The strain PE2 has been preserved, and the preservation name is Pseudoalteromonas sp., preservation unit: General Microbiology Center of China Microbiological Culture Collection Management Committee, preservation address: No. 3, Yard No. 1, Beichen West Road, Chaoyang District,...

Embodiment 2

[0030] Embodiment 2, the growth characteristics of bacterial strain PE2:

[0031] 1. Culture medium:

[0032] 2216E medium (2216E liquid medium): yeast extract 1g, peptone 5g, ferric phosphate 0.01g, sodium chloride 15g, tap water 1000ml, pH7.4.

[0033] Improved MM basal medium: gellan gum 0.5%, sea salt 2.5%, ammonium nitrate 1.0g / L, potassium dihydrogen phosphate 0.5g / L, disodium hydrogen phosphate 1.5g / L, sodium chloride 1.0g / L, seven Magnesium sulfate water 0.2g / L (put last), adjust the pH to 7.2.

[0034] That is, the improved MM basic medium is: 5g gellan gum, 25g sea salt, 1.0g ammonium nitrate, 0.5g potassium dihydrogen phosphate, 1.5g disodium hydrogen phosphate, 1.0g sodium chloride, 1000ml tap water, adjust the pH to 7.2; Finally, 0.2 g of magnesium sulfate heptahydrate was added.

[0035] Composition of PY fermentation medium: 0.2% gellan gum, 0.1% yeast extract, 0.2% peptone; 2.5% sea salt, pH 7.0.

[0036] That is, the PY fermentation medium is: 2 g of gella...

Embodiment 3

[0045] Embodiment 3, utilize Pseudomonas alternata PE2 to produce the method for gellan gum lyase, carry out the following steps successively:

[0046] 1) Transfer an inoculation loop of Pseudomonas alternata PE2 to 100ml 2216E liquid culture based on 200r / min, 30°C for enrichment culture, culture time is 24h; enrichment culture solution is obtained.

[0047] 2), the enriched culture solution obtained in step 1) was connected to the PY fermentation medium at 200r / min, 30°C for activation culture, the culture time was 36h, the enriched culture medium: PY fermentation medium = 1:9 Volume ratio;

[0048] The obtained activated culture solution was centrifuged at 8000 rpm for 15 minutes at 4° C. to obtain the supernatant liquid located in the upper layer and the bacterial cells located in the lower layer respectively.

[0049] 3) Take out the supernatant and keep the lower layer of bacteria, add 0.01M, pH7.0 Tris-HCl buffer 15ml to the bacteria to resuspend, centrifuge at 8000rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com