Fireproof coating and preparation method thereof

A fire-resistant coating and fluorine-silicon modification technology, applied in the field of coatings, can solve the problems of excessive inorganic fillers and affecting the bonding strength of fire-resistant coatings, and achieve the effects of strong adhesion, strong ultraviolet shielding effect, and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

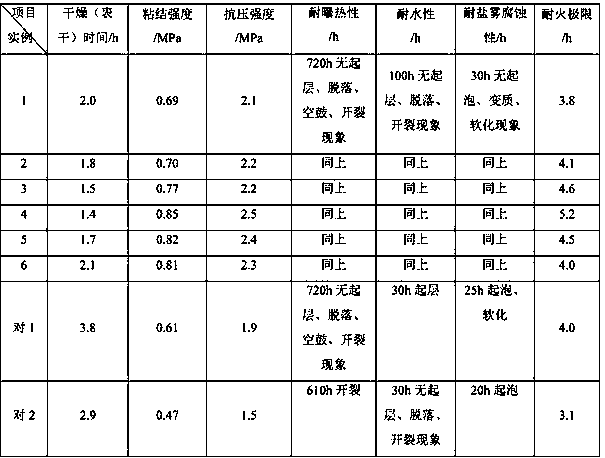

Examples

Embodiment 1

[0027] A kind of fireproof coating is made of the following raw materials in parts by weight:

[0028] Fluorosilicone modified acrylate emulsion 30 parts, water-based polyurethane resin 20 parts, sodium succinate sulfonate 0.6 part, vinyltrimethoxysilane 0.5 part, ammonium polyphosphate 10 parts, zinc borate 12 parts, pentaerythritol 5 parts, silicon 10 parts of algae earth, 7 parts of expanded perlite, γ-Al 2 o 3 0.5 parts, 5 parts of nano-titanium dioxide, 1 part of film-forming agent, 0.02 parts of defoamer and 40 parts of water.

[0029] The preparation method of above-mentioned fluorosilicon modified acrylate emulsion comprises the following steps:

[0030] (1) Mix 0.5 parts of sodium lauryl sulfate, 0.5 parts of OP-10, 0.05 parts of sodium bicarbonate and 30 parts of water, stir for 20 minutes, then add 1 part of methacrylic acid and 6 parts of methacrylic acid dropwise under stirring conditions Methyl ester and 10 parts of butyl acrylate were dropped within 3 hours ...

Embodiment 2

[0042] A kind of fireproof coating is made of the following raw materials in parts by weight:

[0043] Fluorosilicone modified acrylate emulsion 32 parts, water-based polyurethane resin 22 parts, sodium succinate sulfonate 0.8 part, vinyltrimethoxysilane 0.6 part, ammonium polyphosphate 12 parts, zinc borate 13 parts, pentaerythritol 6 parts, silicon 12 parts algae, 9 parts expanded perlite, γ-Al 2 o 3 0.6 parts, 6 parts of nano-titanium dioxide, 1.2 parts of film-forming agent, 0.02 parts of defoamer and 45 parts of water.

[0044] The preparation method of above-mentioned fluorosilicon modified acrylate emulsion comprises the following steps:

[0045] (1) Mix 0.8 parts of sodium lauryl sulfate, 0.6 parts of OP-10, 0.06 parts of sodium bicarbonate and 32 parts of water, stir for 22 minutes, then add 2 parts of methacrylic acid and 7 parts of methacrylic acid dropwise under stirring conditions Methyl ester and 12 parts of butyl acrylate were dropped within 3.5 hours to obt...

Embodiment 3

[0057] A kind of fireproof coating is made of the following raw materials in parts by weight:

[0058] Fluorosilicone modified acrylate emulsion 34 parts, water-based polyurethane resin 25 parts, sodium succinate sulfonate 1.0 part, vinyltrimethoxysilane 0.7 part, ammonium polyphosphate 15 parts, zinc borate 15 parts, pentaerythritol 7 parts, silicon 14 parts algae, 10 parts expanded perlite, γ-Al 2 o 3 0.8 parts, 7 parts of nano-titanium dioxide, 1.5 parts of film-forming agent, 0.03 parts of defoamer and 50 parts of water.

[0059] The preparation method of above-mentioned fluorosilicon modified acrylate emulsion comprises the following steps:

[0060] (1) Mix 1.0 parts of sodium lauryl sulfate, 0.8 parts of OP-10, 0.08 parts of sodium bicarbonate and 35 parts of water, stir for 25 minutes, then add 2.5 parts of methacrylic acid and 8 parts of methacrylic acid dropwise under stirring conditions Methyl ester and 13 parts of butyl acrylate were dropped within 4 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com