Preparation method of styrene-butadiene latex used for architectural coatings and product thereof

A technology of styrene-butadiene latex and architectural coatings, which is applied in the field of architectural coatings, can solve the problems of easy-migration film water resistance, architectural coating water resistance, poor adhesion, and deterioration, so as to achieve good application prospects and market potential, and improve adhesion Excellent effect with water resistance and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A kind of preparation method for the styrene-butadiene latex of building coating, comprises the following steps:

[0030] S1: Add carboxylic acid monomer, (meth)acrylate monomer, butadiene, (methyl)styrene monomer, silane, titanate, molecular weight modifier, emulsifier, initiator to the pressurized reactor agent and distilled water, stirred and mixed, heated, and carried out free radical emulsion copolymerization;

[0031] S2: After the reaction is completed, cool down;

[0032] S3: adding alkali metal hydroxide to adjust the pH to 6-9, and filtering to obtain the styrene-butadiene latex product;

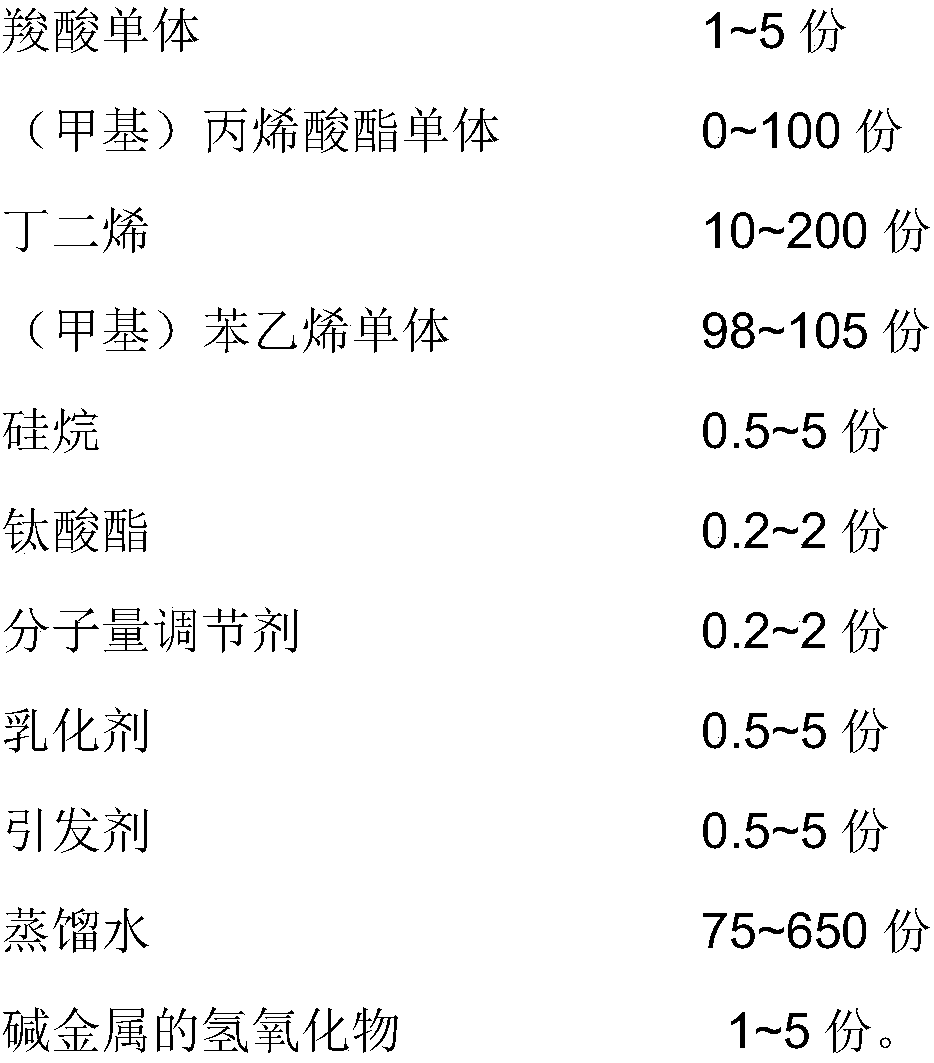

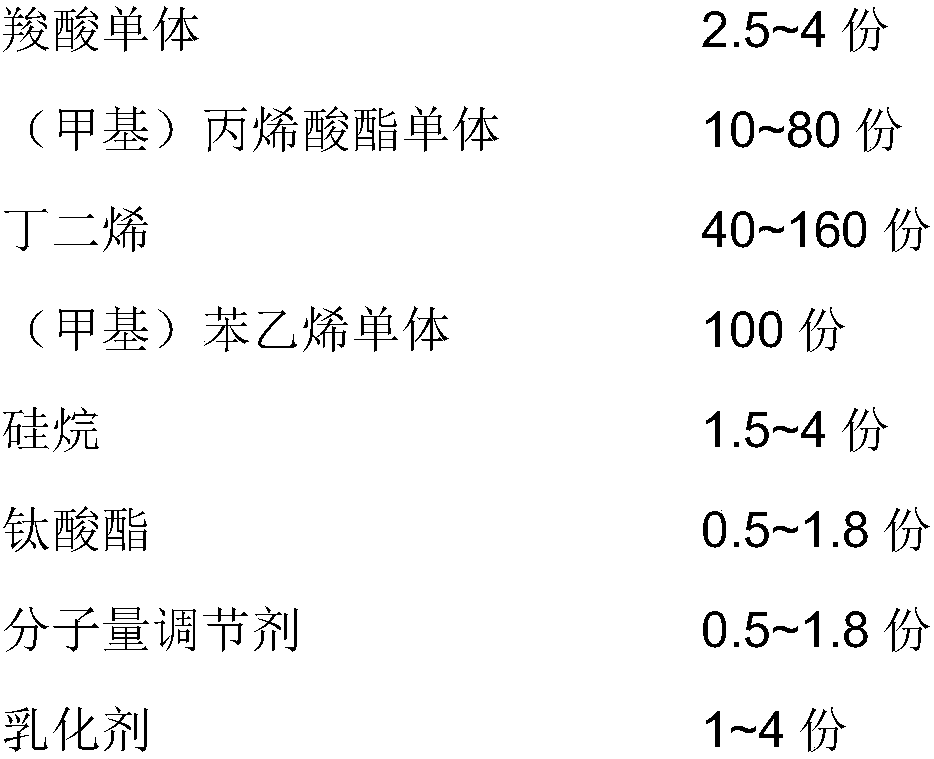

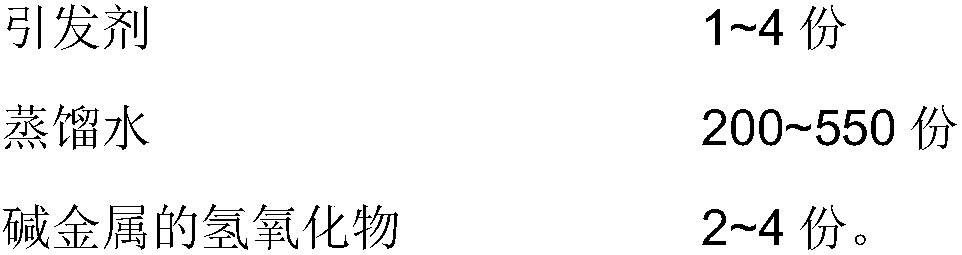

[0033] Wherein, the mass ratio of each material added is:

[0034]

[0035] In a preferred embodiment, the duration of the radical emulsion copolymerization described in S1 is 3-10 hours, and the reaction temperature is 60-90°C.

[0036] In a further preferred embodiment, the carboxylic acid monomer is selected from any one or a combination of more of the following: ac...

Embodiment 1

[0045]Follow the steps below to prepare styrene-butadiene latex:

[0046] First vacuumize the 2000ml pressurized reaction kettle, the vacuum degree is -0.095MPa, add 0.1g of allyl polyoxyethylene ether ammonium sulfate, 0.1g of potassium persulfate, 50g of distilled water, completely dissolve into an aqueous solution, start stirring, and heat up to 60 ℃; at the same time, dropwise add 1 gram of acrylic acid, 10 gram of butadiene, 100 gram of styrene, 0.2 gram of n-dodecanethiol, 0.2 gram of isopropyl tri(dioctyl pyrophosphate acyloxy)titanium at 60 ℃ Ester, 0.5 grams of γ-methacryloxypropyltrimethoxysilane mixed monomer; and dropwise added 0.4 grams of allyl polyoxyethylene ether ammonium sulfate, 0.4 grams of potassium persulfate, 21.93 grams of distilled water Aqueous solution; the total time of adding drops is 6 hours, fully stirred. After the dropwise addition was completed, the temperature was kept at 60° C. for 4 hours. After completion of the reaction, cool to 25°C, n...

Embodiment 2

[0048] Follow the steps below to prepare styrene-butadiene latex:

[0049] First vacuumize the 2000ml pressurized reactor, the vacuum degree is -0.095MPa, add 2 grams of allyl polyoxyethylene ether ammonium sulfate, 1 gram of sodium persulfate, 500 grams of distilled water, 5 grams of styrene, completely dissolve into an aqueous solution, and open Stir and heat up to 90°C; at the same time, dropwise add 5 grams of methacrylic acid, 50 grams of n-butyl acrylate, 50 grams of methyl methacrylate, 200 grams of butadiene, 95 grams of methyl styrene, 2 gram tert-dodecyl mercaptan, 2 gram isopropyl trioleate acyloxy titanate, 2 gram N-2-(aminoethyl)-3-aminopropyltrimethoxysilane, 3 gram γ-(2 , the mixed monomer of 3-glycidoxy) propyl trimethoxysilane; And dropwise add the mixed aqueous solution of 3 gram allyl polyoxyethylene ethers, 4 gram sodium persulfate, 111 gram distilled water; The total time of dropping is 2 hours, stirring well. After the dropwise addition was completed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com