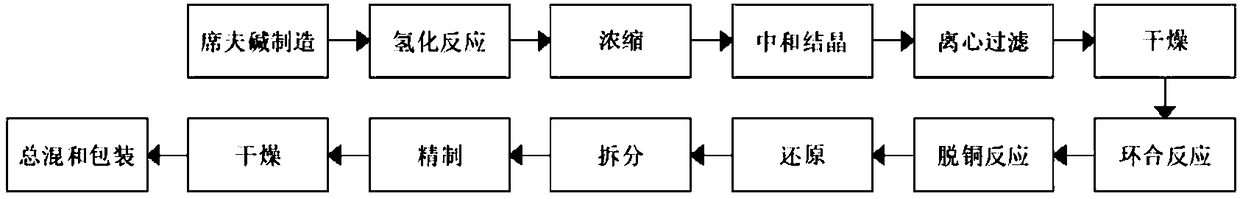

Production process of rotundine

A production process, the technology of rotundine, which is applied in the direction of organic chemistry, can solve the problems of secondary injury, high side effects, and short efficacy maintenance time of patients, and achieve the effects of long efficacy maintenance time, reduction of side effects, and improvement of efficacy time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This kind of rotundine production technology comprises the steps:

[0027] S1: Manufacture of Schiff's base: Add piperethylamine measured by a balance scale into the condensation tank, add polyoxymethylene under stirring, open the vacuum system to make the vacuum in the tank reach 0.055MPa, and then slowly heat in the interlayer water bath to make the block The methyl-ortho-vanillin is completely dissolved, and the stirring is stopped. Intense foam is produced during the reaction, and the temperature continues to rise. At this time, water droplets can be seen in the cup. When there are no water droplets in the cup, it is the end of the reaction. Continue to keep warm 15.5 minutes, holding temperature 155°C, cooling down to below 60°C, pumping into the autoclave;

[0028] S2: Hydrogenation reaction: pump the catalyst into the autoclave. After all the materials are added, the liquid level reaches the turbine position of the autoclave. After repeated ventilation with hydro...

Embodiment 2

[0041] This kind of rotundine production technology comprises the steps:

[0042] S1: Manufacture of Schiff's base: Add piperethylamine measured by a balance scale into the condensation tank, add polyoxymethylene under stirring, open the vacuum system to make the vacuum in the tank reach 0.05MPa, and then slowly heat in the interlayer water bath to make the block The methyl-ortho-vanillin is completely dissolved, and the stirring is stopped. Intense foam is produced during the reaction, and the temperature continues to rise. At this time, water droplets can be seen in the cup. When there are no water droplets in the cup, it is the end of the reaction. Continue to keep warm 15 minutes, keep warm at 150°C, cool down to below 60°C, and pump into the autoclave;

[0043] S2: Hydrogenation reaction: pump the catalyst into the autoclave. After all the materials are added, the liquid level reaches the turbine position of the autoclave. After repeated ventilation with hydrogen for thre...

Embodiment 3

[0056] This kind of rotundine production technology comprises the steps:

[0057] S1: Manufacture of Schiff's base: Add piperethylamine measured by a balance scale into the condensation tank, add polyoxymethylene under stirring, open the vacuum system to make the vacuum in the tank reach 0.06MPa, and then slowly heat in the interlayer water bath to make the block The methyl-ortho-vanillin is completely dissolved, and the stirring is stopped. Intense foam is produced during the reaction, and the temperature continues to rise. At this time, water droplets can be seen in the cup. When there are no water droplets in the cup, it is the end of the reaction. Continue to keep warm 16 minutes, holding temperature 160°C, cooling down to below 60°C, pumping into the autoclave;

[0058] S2: Hydrogenation reaction: pump the catalyst into the autoclave. After all the materials are added, the liquid level reaches the turbine position of the autoclave. After repeated ventilation with hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com