A method for the continuous preparation of chiral α-hydroxy-β-dicarbonyl compounds by visible light-catalyzed molecular oxygen oxidation via a microreactor

A technology of dicarbonyl compounds and microreactors, which is applied in the field of flow chemistry to achieve the effect of mild reaction conditions and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

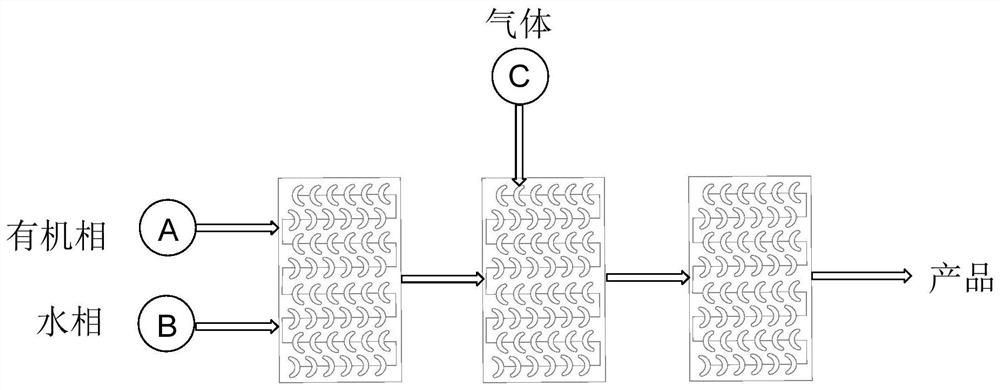

Method used

Image

Examples

Embodiment 1

[0028]

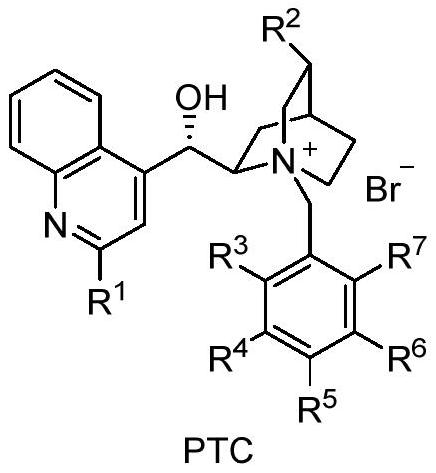

[0029] Take by weighing 0.05mmol 1-indanone-2-carboxylate adamantyl (Ia-1), 10% PTC-2, 1% tetraphenylporphyrin, put into 10ml test tube, add 5ml toluene, solid dissolves completely, and is recorded as A bottle; another 0.5% potassium carbonate solution is prepared, which is recorded as bottle b, at 0°C, the light source is white light, the organic phase in bottle a is pumped from pump A at a rate of 0.3ml / min, and the alkaline solution in bottle b is pumped from pump B at a rate of The flow rate of oxygen into C is 0.3ml / min, the flow rate of oxygen is 1ml / min, and the residence time is about 1.5min. The conversion rate of the reaction reaches 99.9%, the selectivity of α-hydroxylation product is more than 95%, and the ee value is 84%.

Embodiment 2

[0031]

[0032] Take by weighing 0.05mmol 1-indanone-2-carboxylate adamantyl (Ia-1), 10% PTC-2, 1% tetraphenylporphyrin, put into 10ml test tube, add 5ml toluene, solid dissolves completely, and is recorded as bottle a; another 0.5% potassium carbonate solution is prepared, which is recorded as bottle b, at 0°C, the light source is white light, the organic phase in bottle a is pumped from pump A at a rate of 1.5ml / min, and the alkaline solution in bottle b is pumped from pump B at a rate of The flow rate of oxygen into C is 1.5ml / min, the flow rate of oxygen is 2ml / min, and the residence time is about 1.5min. The conversion rate of the reaction reaches 99.9%, the selectivity of α-hydroxylation product is more than 95%, and the ee value is 80%.

Embodiment 3

[0034]

[0035] Take by weighing 0.05mmol 1-indanone-2-carboxylate adamantyl (Ia-1), 10% PTC-3, 1% tetraphenylporphyrin, put into 10ml test tube, add 5ml toluene, solid dissolves completely, and is recorded as bottle a; another 0.5% potassium carbonate solution is prepared, which is recorded as bottle b, at 0°C, the light source is white light, the organic phase in bottle a is pumped from pump A at a rate of 1.5ml / min, and the alkaline solution in bottle b is pumped from pump B at a rate of The flow rate of oxygen into C is 1.5ml / min, the flow rate of oxygen is 2ml / min, and the residence time is about 1.5min. The conversion rate of the reaction reaches 99.9%, the selectivity of α-hydroxylation product is more than 95%, and the ee value is 84%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com