Preparation method and application of sodium-rich anhydrous prussian blue analogue material

A technology of Prussian blue and its analogues, which is applied in the field of anode materials for sodium ion secondary batteries, can solve the problems of Prussian analogues such as large difference in actual capacity and theoretical capacity, decrease in cycle stability and rate performance, and influence on ion redox reactions. Achieve the effect of excellent shape, good cycle performance and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

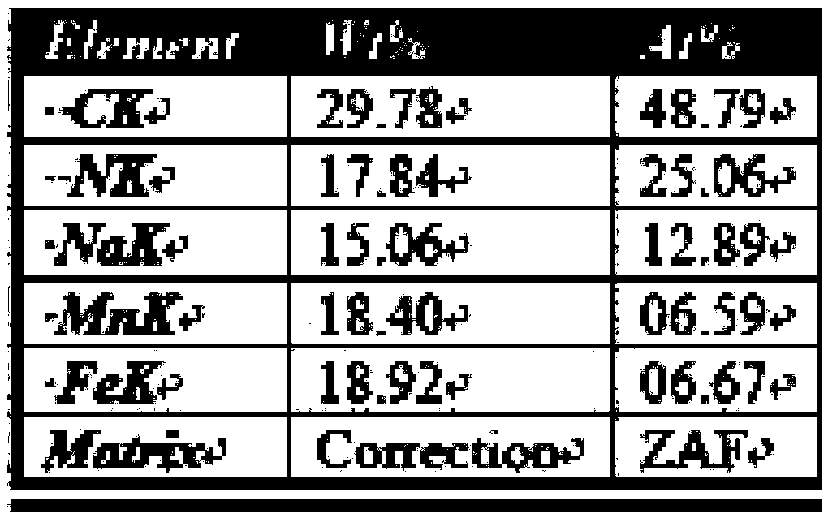

Image

Examples

Embodiment 1

[0025] Weigh 1.82g sodium ferrocyanide, 36g sodium chloride and 1.20g manganese chloride, add sodium ferrocyanide to 100ml deionized water, stir for 30min to form solution A, add sodium chloride to solution A to form Saturated solution B of sodium chloride, continue to stir for 30min. Dissolve manganese chloride in 100ml of deionized water, stir evenly, add dropwise to the above saturated solution B, stir for 24 hours to form a suspension.

[0026] The solid material in the suspension was collected by a centrifuge with a centrifugal speed of 8000r / min, washed 3 times with deionized water until there was no remaining sodium chloride in the product, and suction filtered to obtain a sodium-rich Prussian blue analog material. Dry in a vacuum oven at 100°C for 24 hours.

[0027] Grind the dried sodium-rich Prussian blue analogue into powder, spread it in the ark, and place it in the constant temperature zone of the tube furnace for calcination: with Ar as the inert gas source, fir...

Embodiment 2

[0030] Weigh 1.82g sodium ferrocyanide, 34g sodium chloride and 1.20g manganese chloride, add sodium ferrocyanide to 100ml deionized water, stir for 30min to form solution A, add sodium chloride to solution A to form Saturated solution B of sodium chloride, continue to stir for 30min. Dissolve manganese chloride in 100ml of deionized water, stir evenly, add dropwise to the above saturated solution B, stir for 24 hours to form a suspension. The solid material in the suspension was collected by a centrifuge with a centrifugal speed of 8000r / min, washed 3 times with deionized water until there was no remaining sodium chloride in the product, and suction filtered to obtain a sodium-rich Prussian blue analog material. Dry in a vacuum oven at 100°C for 24 hours. The dried sodium-rich Prussian blue analogue is ground into powder, spread in the ark, and placed in the constant temperature zone of the tube furnace for calcination: with N 2 As the source of inert gas, the inert gas was...

Embodiment 3

[0032] Weigh 1.82g sodium ferrocyanide, 36g sodium chloride and 1.20g manganese chloride, add sodium ferrocyanide to 100ml deionized water, stir for 20min to form solution A, add sodium chloride to solution A to form Saturated solution B of sodium chloride, continue to stir for 20min. Dissolve manganese chloride in 100ml of deionized water, stir well, then add dropwise into the above saturated solution B, stir for 24 hours to form a suspension. The solid material in the suspension was collected by a centrifuge with a centrifugal speed of 8000r / min, washed 3 times with deionized water until there was no remaining sodium chloride in the product, and suction filtered to obtain a sodium-rich Prussian blue analog material. Dry in a vacuum oven at 100°C for 24 hours. Grind the dried sodium-rich Prussian blue analogue into powder, spread it in the ark, and place it in the constant temperature zone of the tube furnace for calcination: with He as the inert gas source, first pass the ine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com