A super high temperature resistant flat belt

A flat belt, high temperature resistant technology, applied in the field of belt transmission, can solve the problems of low heat resistance temperature, poor wear resistance, etc., achieve the effect of improving adhesion performance, regular internal structure, and overcoming performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

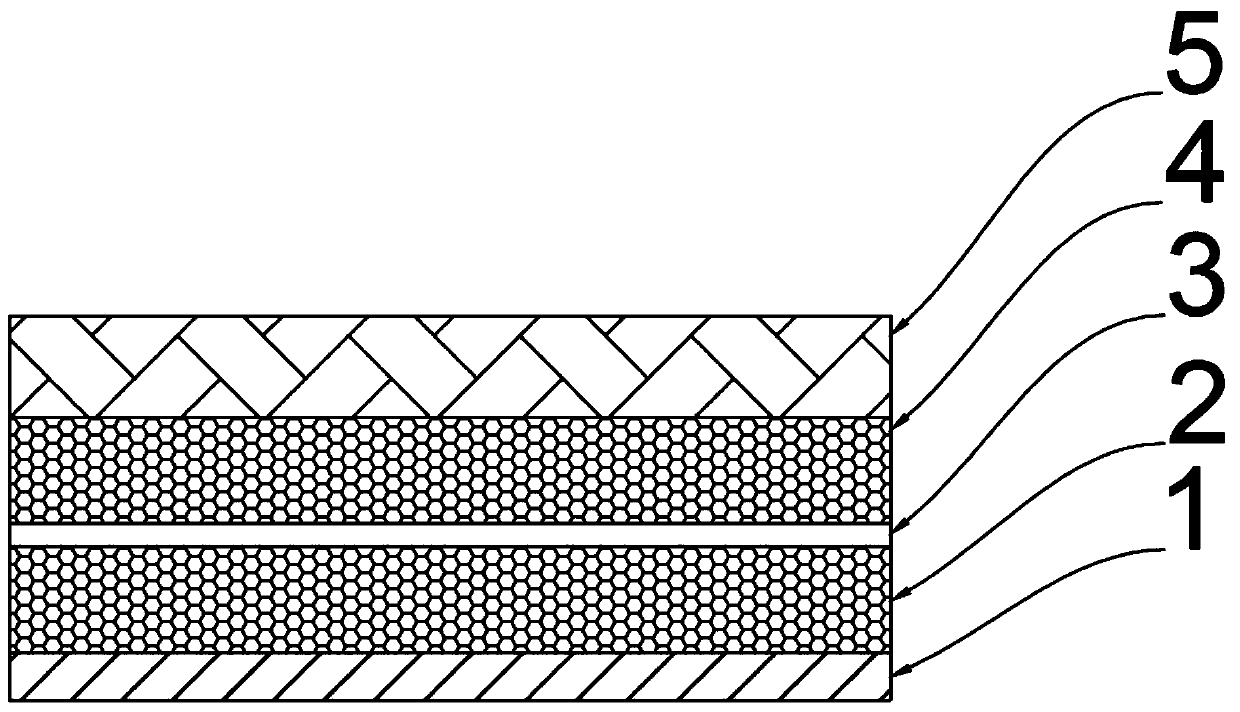

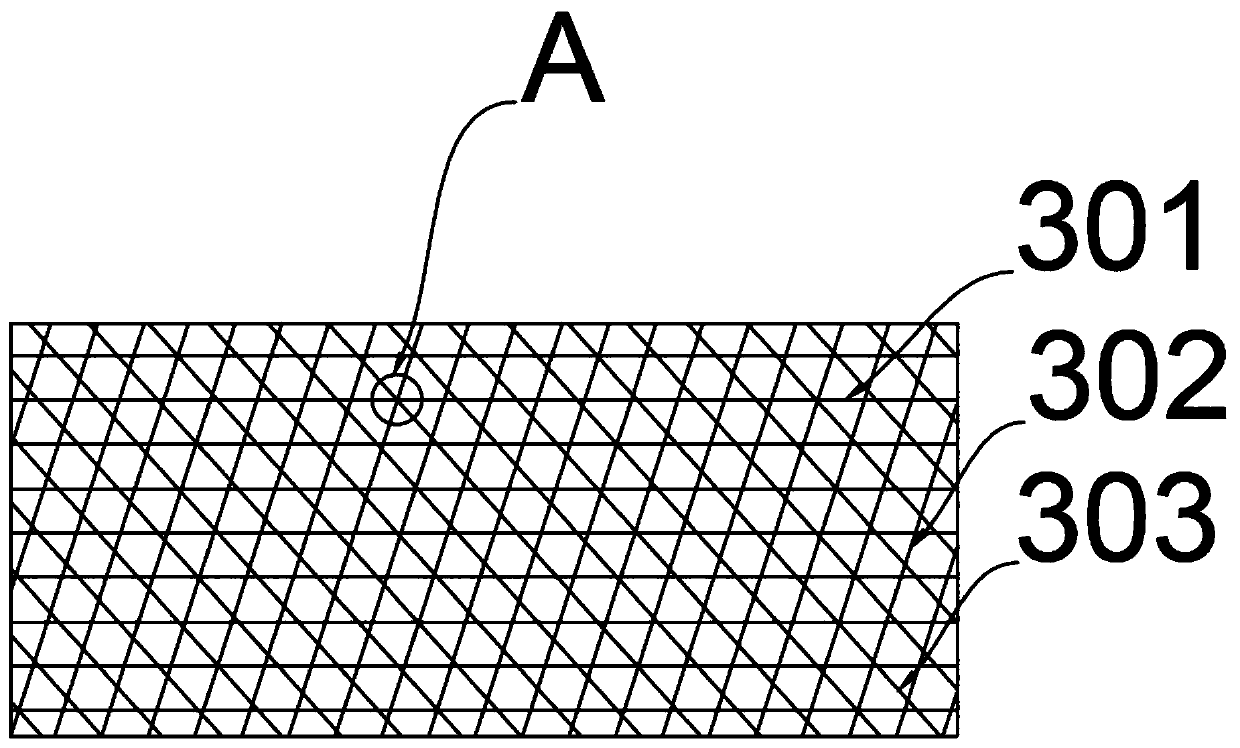

[0035] Such as figure 1 , figure 2 with image 3 As shown, a flat belt with super high temperature resistance includes a bottom surface, an intermediate reinforcement layer and a main body covering layer, and the flat belt also includes a first buffer rubber 2 and a second buffer rubber 4 processed by fluororubber, and the bottom surface is fluororubber rubber Aramid fiber cloth 1 treated with pulp, the middle reinforcing layer is an aramid fiber thread layer 3 composed of aramid fiber threads treated with fluororubber glue, and the subject covering layer 5 is fluororubber;

[0036] The aramid fiber cloth 1 is coated with the first buffer glue 2 on one side, and then the aramid fiber thread is wound on the first buffer glue 2 to form an aramid fiber thread layer 3, and then the aramid fiber A layer of second buffer glue 4 is coated on the line layer 3, and finally the main body covering layer 5 is coated on the second buffer glue 4 to obtain a plane belt skeleton, and the p...

Embodiment 2

[0051] A super high temperature resistant flat belt, including a bottom surface, an intermediate reinforcement layer and a main body covering layer, the flat belt also includes a first buffer rubber 2 and a second buffer rubber 4 processed by fluororubber, and the bottom surface is processed by fluororubber glue Aramid fiber cloth 1, the middle reinforcement layer is an aramid fiber line layer 3 composed of aramid fiber lines treated with fluororubber glue, and the subject covering layer 5 is fluororubber;

[0052] The aramid fiber cloth 1 is coated with the first buffer glue 2 on one side, and then the aramid fiber thread is wound on the first buffer glue 2 to form an aramid fiber thread layer 3, and then the aramid fiber A layer of second buffer glue 4 is coated on the line layer 3, and finally the main body covering layer 5 is coated on the second buffer glue 4 to obtain a plane belt skeleton, and the plane belt skeleton is trimmed and then placed in a hot The vulcanizing m...

Embodiment 3

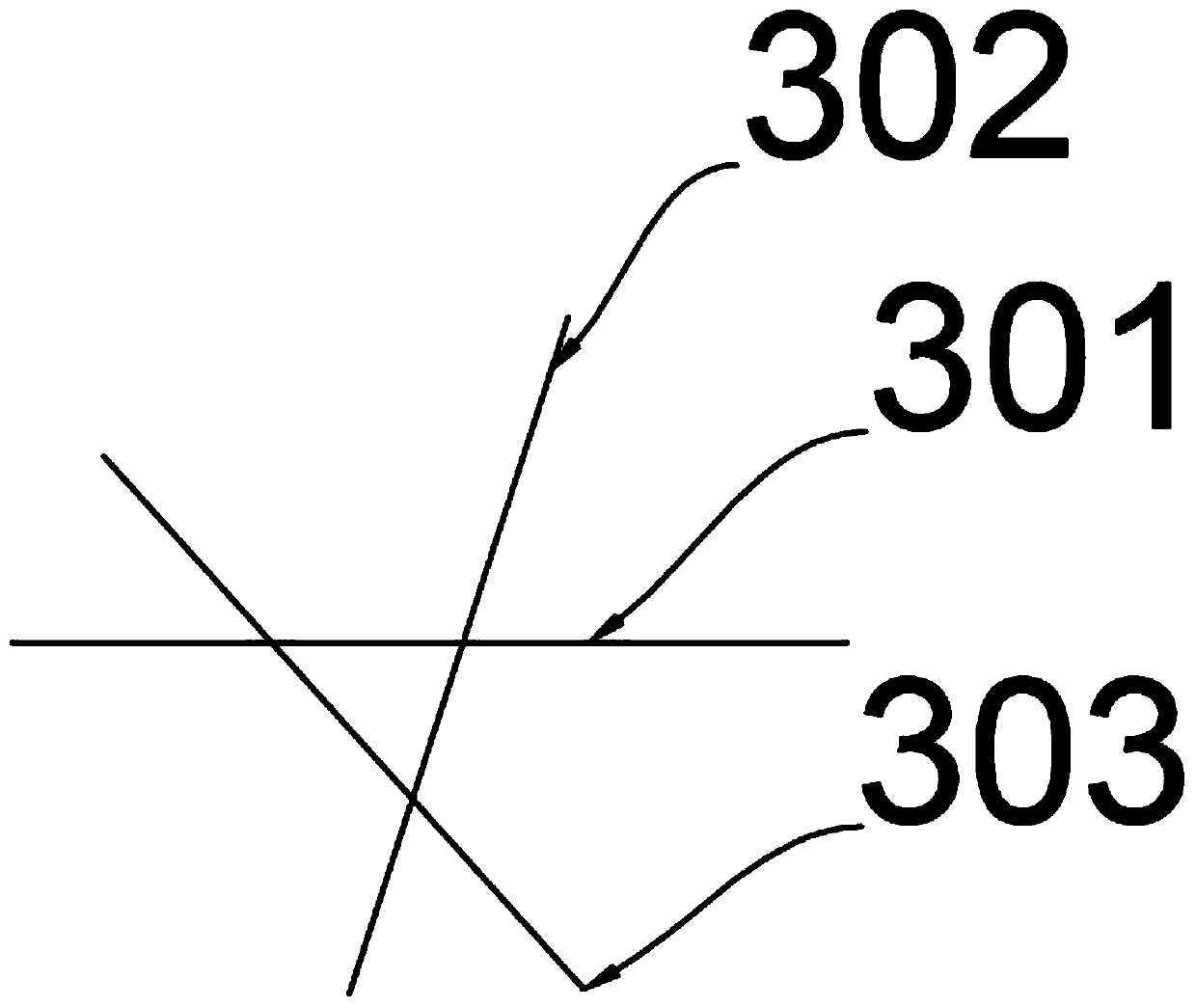

[0067] The ultra-high temperature resistant flat belt of this embodiment is basically the same as that of Embodiment 1, the main difference being that the angle range between the first aramid fiber line 301 and the second aramid fiber line 302 is 45 degrees, The included angle formed by the first aramid fiber line 301 and the third aramid fiber line 303 is 135 degrees.

[0068] The steps of the thermal vulcanization overlapping operation are as follows: firstly carry out the first-stage vulcanization at a temperature of 165° C. and a pressure of 10 MPa for 15 minutes, and then gradually raise the temperature to 230° C. for a second-stage vulcanization for 24 hours.

[0069] The aramid fiber cloth 1 processed by the fluororubber glue, in its specific processing method:

[0070] Preparation of S1 fluororubber mortar: Weigh 100 parts by weight of fluororubber and add it to an open mill with a roll distance of 0.4mm for 9 times of plasticizing; add the plasticized fluororubber to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com