Ultrahigh-pressure abrasive jet generating device based on ejector mechanism

A generating device and abrasive jet technology, which is applied in the direction of abrasive feeding device, used abrasive processing device, explosion generating device, etc., can solve the problem of acceleration of abrasive mixed liquid, replenishment of abrasive jet abrasive concentration, and inability to increase abrasive mixed liquid Problems such as the secondary mixing effect can be achieved to increase the striking force and solve the effect of uneven concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

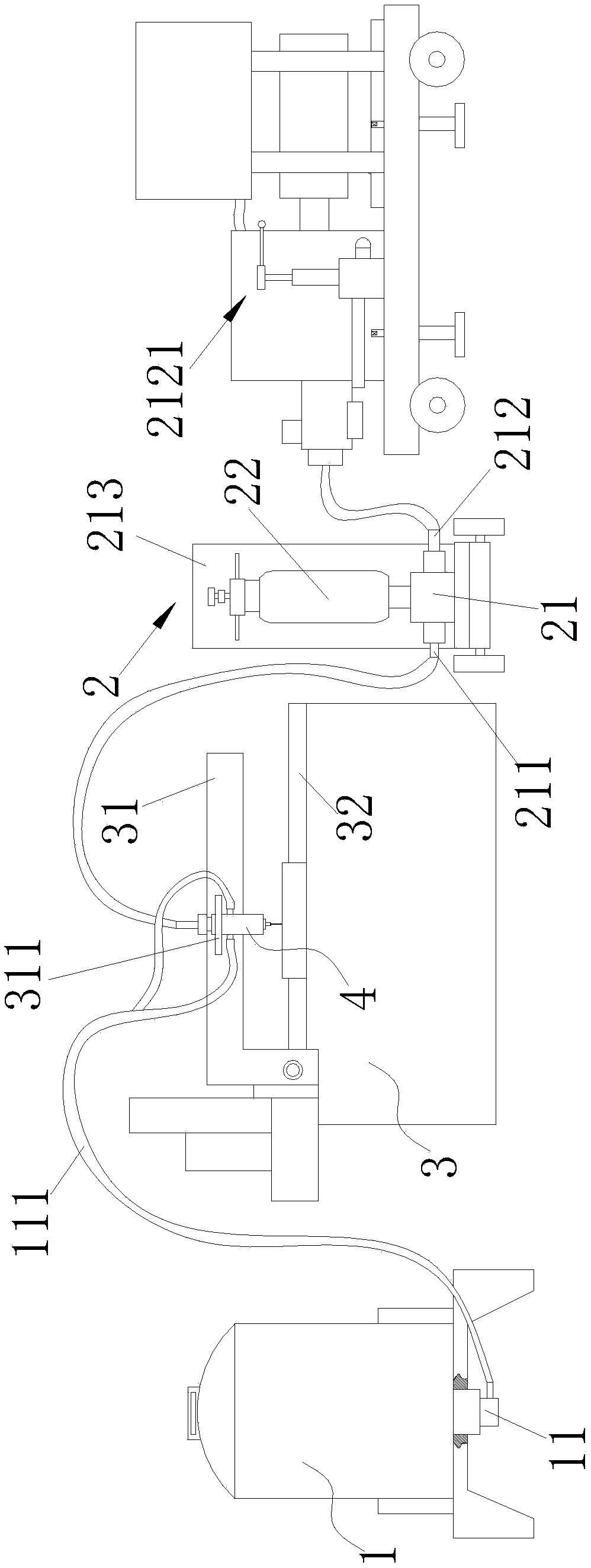

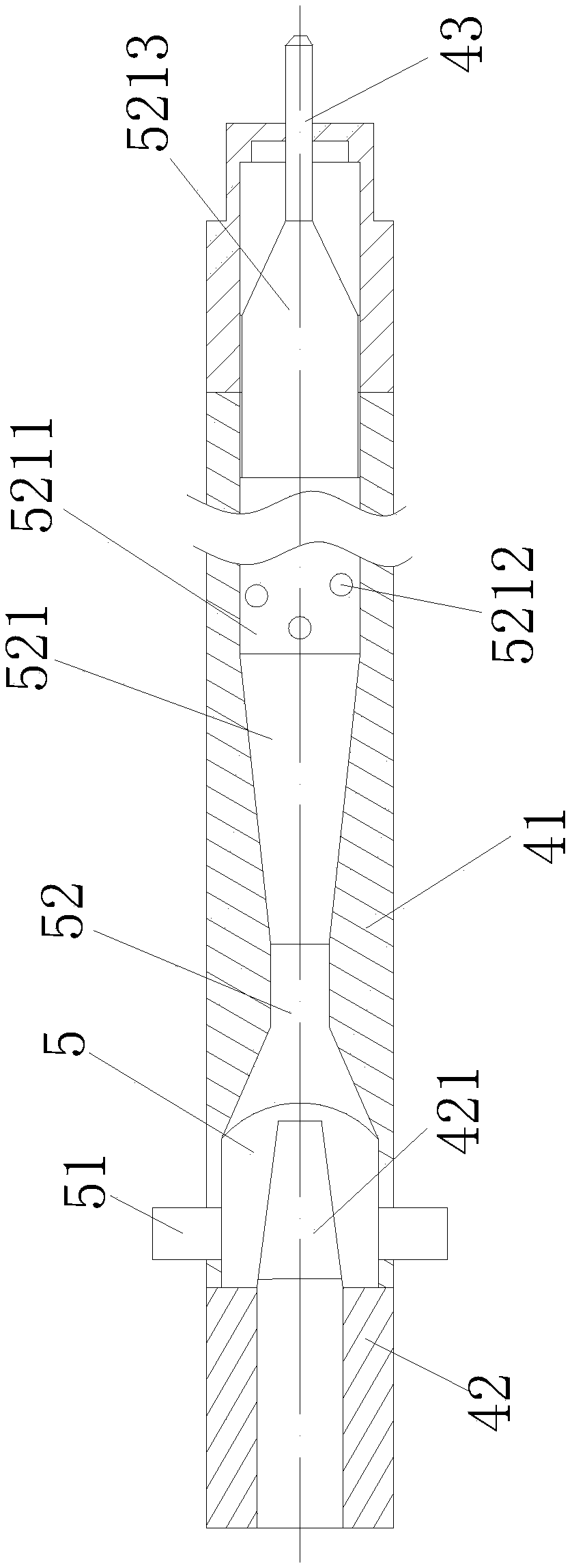

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the ultra-high-pressure abrasive jet generator based on the ejection mechanism includes an air-supplementing dry sand tank 1, a pre-mixed abrasive generator 2 and a numerically controlled machine tool 3, and also includes an ejector secondary sand mixing tube 4. The ejection secondary sand mixing pipe 4 includes an ejection pipe 41 and a main output pipe 42, the right end of the main output pipe 42 installed in the ejection pipe 41, and an ejection cavity 5 is provided in the ejection pipe 41 , the injection cavity 5 is also located at the left end of the injection tube 41, the end of the main output tube 42 is provided with a tapered port 421, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com