Double-crosslinked gel-based micro-fluidic chip and manufacturing method thereof

A microfluidic chip and secondary cross-linking technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problem that the bonding interface is easy to break, the bonding process is not strong enough, and cannot be realized Bifurcated structure flow channel structure and other issues to achieve the effect of good biocompatibility, easy operation and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Taking the fabrication of a gelatin-GelMA-based microfluidic chip with a bifurcated flow channel and the construction of a blood vessel chip as examples, the manufacturing process mentioned in the present invention is further described.

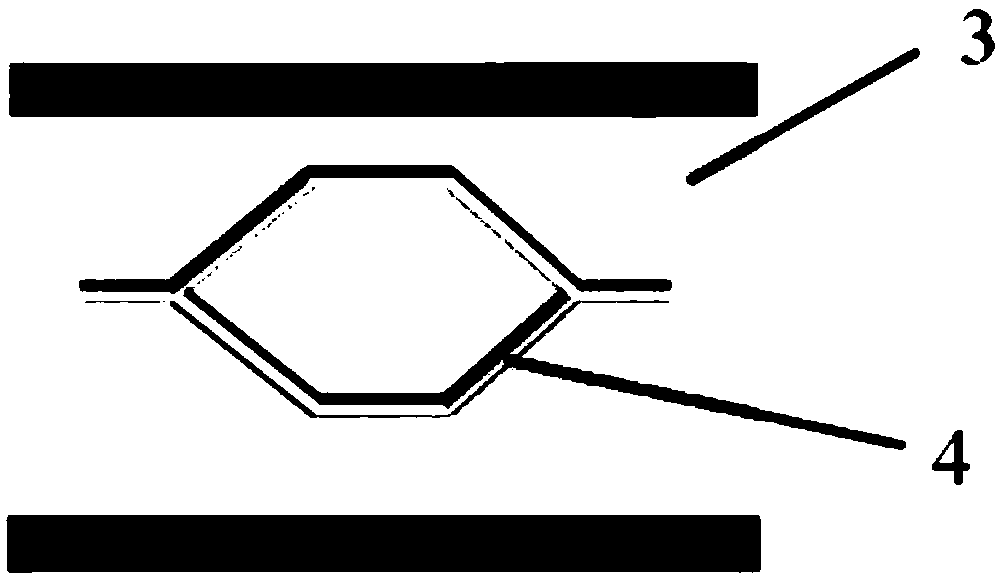

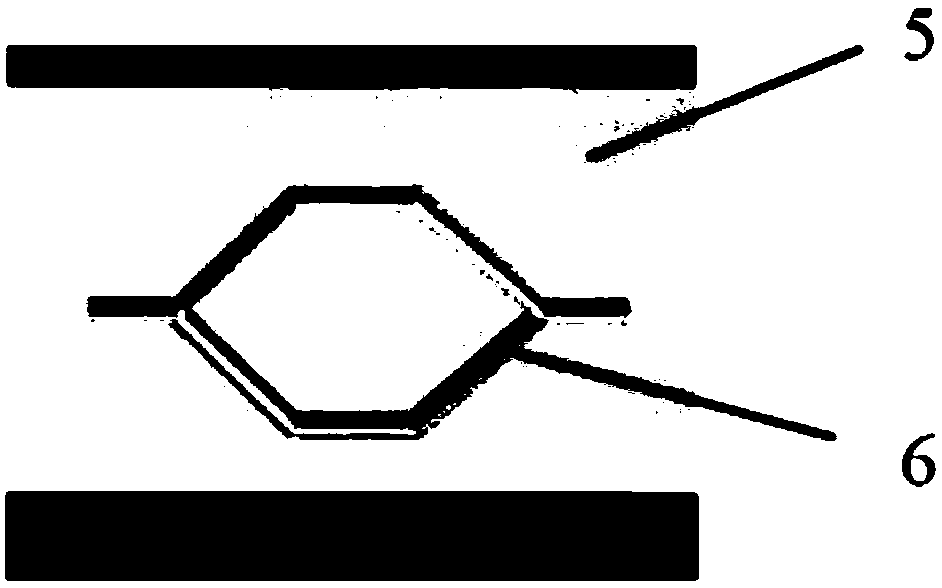

[0070] figure 1 The 3D model of the mold showing the designed bifurcated runners starts the mold manufacturing process. Existing printing materials can be selected, and corresponding 3D printing methods can be used, such as polylactic acid, photosensitive resin, etc., FDM 3D printing, photocuring printing, etc. can be used, and existing micro-manufacturing processes or traditional machining processes can also be used. , In this embodiment, a photosensitive resin is selected, and a photocuring printing method is used. After the printing is completed, the photosensitive resin mold 1 is removed from the printer, and the inner cavity of the photosensitive resin mold 1 has a mold convex groove 2 for forming a bifurcated groove structure an...

Embodiment 2

[0081] Taking the manufacture of a gelatin-sodium alginate-based microfluidic chip as an example, the manufacturing process mentioned in the present invention is further described.

[0082] Weigh a certain amount of gelatin and sodium alginate particles, and dissolve the gelatin and sodium alginate with deionized water through constant temperature magnetic stirring at 37 degrees to obtain a composite hydrogel precursor solution of 2% sodium alginate and 9% w / v gelatin , placed in a 37-degree water bath for later use.

[0083] The prepared composite hydrogel precursor solution was poured into the assembled mold.

[0084] Put it in a 4-degree refrigerator and take it out after standing for 10 minutes;

[0085] The mold is disassembled, and the partially cross-linked composite hydrogel is released from the mold to obtain a hydrogel sheet with bifurcation-shaped grooves on the surface;

[0086] The grooved surfaces of two such hydrogel sheets are closely attached, soaked in 4% c...

Embodiment 3

[0088] Taking the manufacture of a sodium alginate-GelMA-based microfluidic chip as an example, the manufacturing process mentioned in the present invention is further described.

[0089] Prepare 1% w / v (gram / ml) LAP solution with basic medium and LAP powder, weigh a certain amount of GelMA material, dissolve GelMA by vortex oscillation with LAP solution, and obtain 10% w / v (gram / ml) ) GelMA precursor solution, filtered through a 220nm filter; weigh a certain amount of sodium alginate particles, and use the GelMA precursor solution to dissolve sodium alginate through 37-degree constant temperature magnetic stirring to obtain 2% w / v (g / ml) Sodium alginate, 10% GelMA w / v (g / ml) composite hydrogel precursor solution, placed in a 37 degree water bath for use.

[0090] The prepared composite hydrogel precursor solution was poured into the assembled mold.

[0091] Soak it in 4% calcium chloride solution, let it stand for 10 minutes and take it out;

[0092] The mold is disassembled,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com