Button lithium battery adopting lithium-ion solid electrolytic sheet as diaphragm and preparation method of battery

A technology of solid electrolyte and lithium ion, which is applied in the field of button lithium battery and its preparation, and can solve the problem of low electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A kind of button lithium battery with lithium ion solid electrolyte sheet as diaphragm of the present invention, it comprises parts and is: lithium ion solid electrolyte sheet, positive electrode sheet (LiFePO 4 , aluminum foil, PVDF binder, acetylene black, NMP solvent), positive electrode casing, lithium sheet, negative electrode casing, electrolyte LiPF 6 , filter paper sheet, stainless steel sheet and shrapnel, the lithium ion solid electrolyte sheet is Li after sintering 0.2 La 0.6 TiO 3 Ceramics;

[0063] The model of the positive electrode casing, negative electrode casing, stainless steel sheet, and shrapnel is CR2032, the appearance size is 20mm in diameter, and the thickness is 3.2mm;

[0064] The positive plate is made of commercial product LiFePO 4 , aluminum foil, PVDF binder, acetylene black, NMP preparation, mass ratio LiFePO 4 : PVDF (dissolved in NMP, the mass ratio of PVDF and NMP is 1:19): acetylene black=8:20:1, the diameter of the positive elec...

Embodiment 2

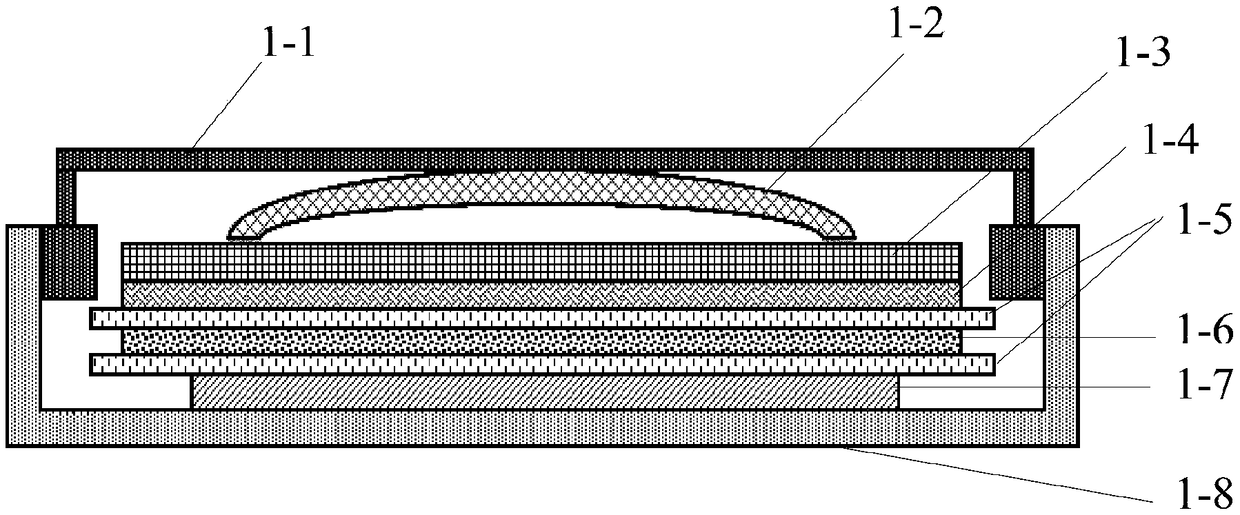

[0084] A kind of button lithium battery that uses lithium ion solid electrolyte sheet as separator of the present invention, its half-battery sectional view is as follows figure 1 As shown, 1-1 is the negative electrode shell; 1-2 is the shrapnel; 1-3 is the stainless steel sheet; 1-4 is the lithium sheet; 1-5 is the filter paper soaked in the electrolyte; 1-6 is the lithium ion solid electrolyte sheet; 1-7 is the positive electrode sheet; 1-8 is the positive electrode shell, and the lithium ion solid electrolyte sheet is sintered Li 0.25 La 0.583 TiO 3 Ceramics;

[0085] It includes components: lithium ion solid electrolyte sheet 1-6, positive electrode sheet (LiFePO 4 , aluminum foil, PVDF binder, acetylene black, NMP solvent) 1-7, positive electrode case 1-8, lithium sheet 1-4, negative electrode case 1-1, electrolyte LiPF 6 , filter paper 1-5, stainless steel 1-3, shrapnel 1-2;

[0086] The model of the positive electrode casing 1-8, the negative electrode casing 1-1,...

Embodiment 3

[0107]A kind of button lithium battery with lithium ion solid electrolyte sheet as diaphragm of the present invention, it comprises parts and is: lithium ion solid electrolyte sheet, positive electrode sheet (LiFePO 4 , aluminum foil, PVDF binder, acetylene black, NMP solvent), positive electrode casing, lithium sheet, negative electrode casing, electrolyte LiPF 6 , filter paper sheet, stainless steel sheet, shrapnel, described lithium ion solid electrolyte sheet is Li after sintering 0.33 La 0.557 TiO 3 Ceramics;

[0108] The model of the positive electrode casing, negative electrode casing, stainless steel sheet, and shrapnel is CR2032, the appearance size is 20mm in diameter, and the thickness is 3.2mm;

[0109] The positive plate is made of commercial product LiFePO 4 , aluminum foil, PVDF binder, acetylene black, NMP preparation, mass ratio LiFePO 4 : PVDF (dissolved in NMP, the mass ratio of PVDF and NMP is 1:19): acetylene black=8:20:1, the diameter of the positive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Li-ion conductivity | aaaaa | aaaaa |

| Electronic conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com